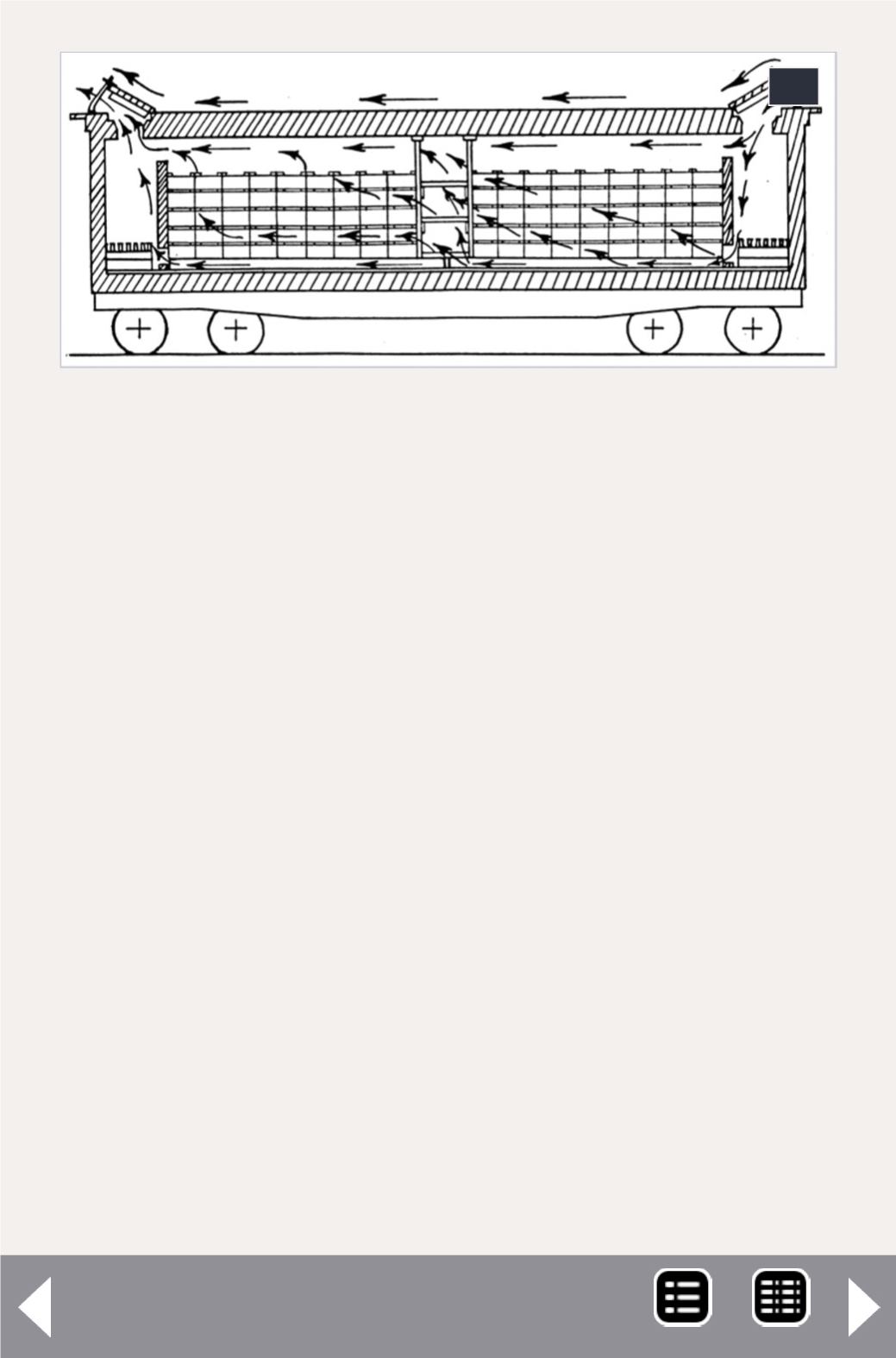

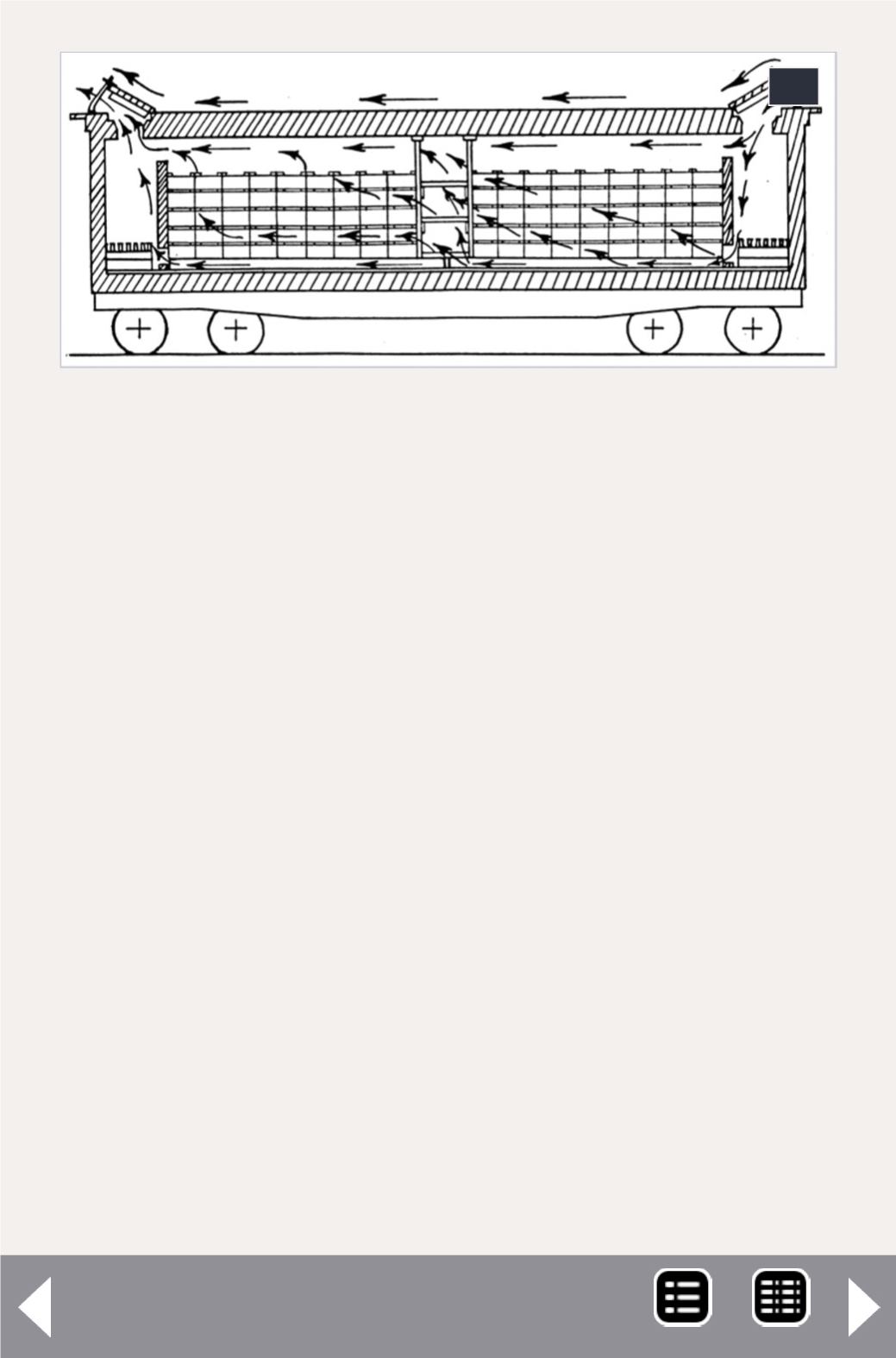

12: This SP diagram shows air flow through a car set

up for ventilation service. Note that the load does not

reach to the car ceiling, to help with air flow, and that

dunnage at the car center will allow easier unloading.

– Author’s collection.

12

locations only, or any other of a variety arrangements. In cooler

weather, when less ice would be consumed, stage icing could

be chosen. This meant setting ice grates at half height in the

bunker, so that filling to the top with ice would leave the bot-

tom half of the bunker empty (see Figure 2). This maintained

good air circulation, while allowing all cars to be re-iced the

same way: filling the bunkers to the top.

At an icing deck, foremen would go down the string of cars,

opening ice hatches and estimating by eye the amount of ice

needed to fill the bunker to the top. They noted this on a clip-

board as they went from car to car. The ice usage for each car

was charged to the freight bill for the car. Occasionally the

ICC would conduct a field test, checking how accurate these

foreman’s estimates were, and they were usually found to be

quite accurate.

The process would continue all the way to the car’s desti-

nation. Many cars were directed to eastern or midwestern

contents