Getting Real Column - 7

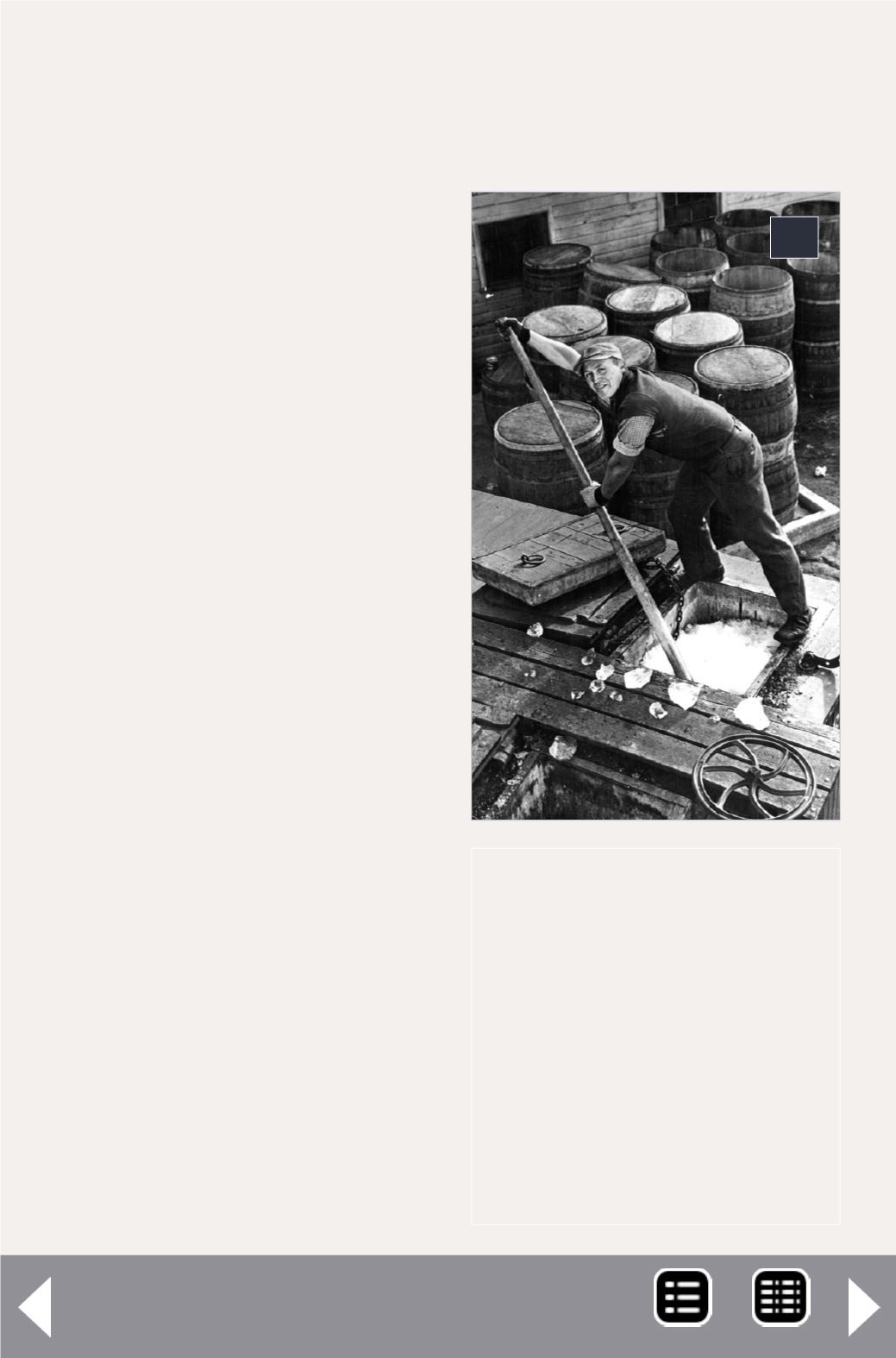

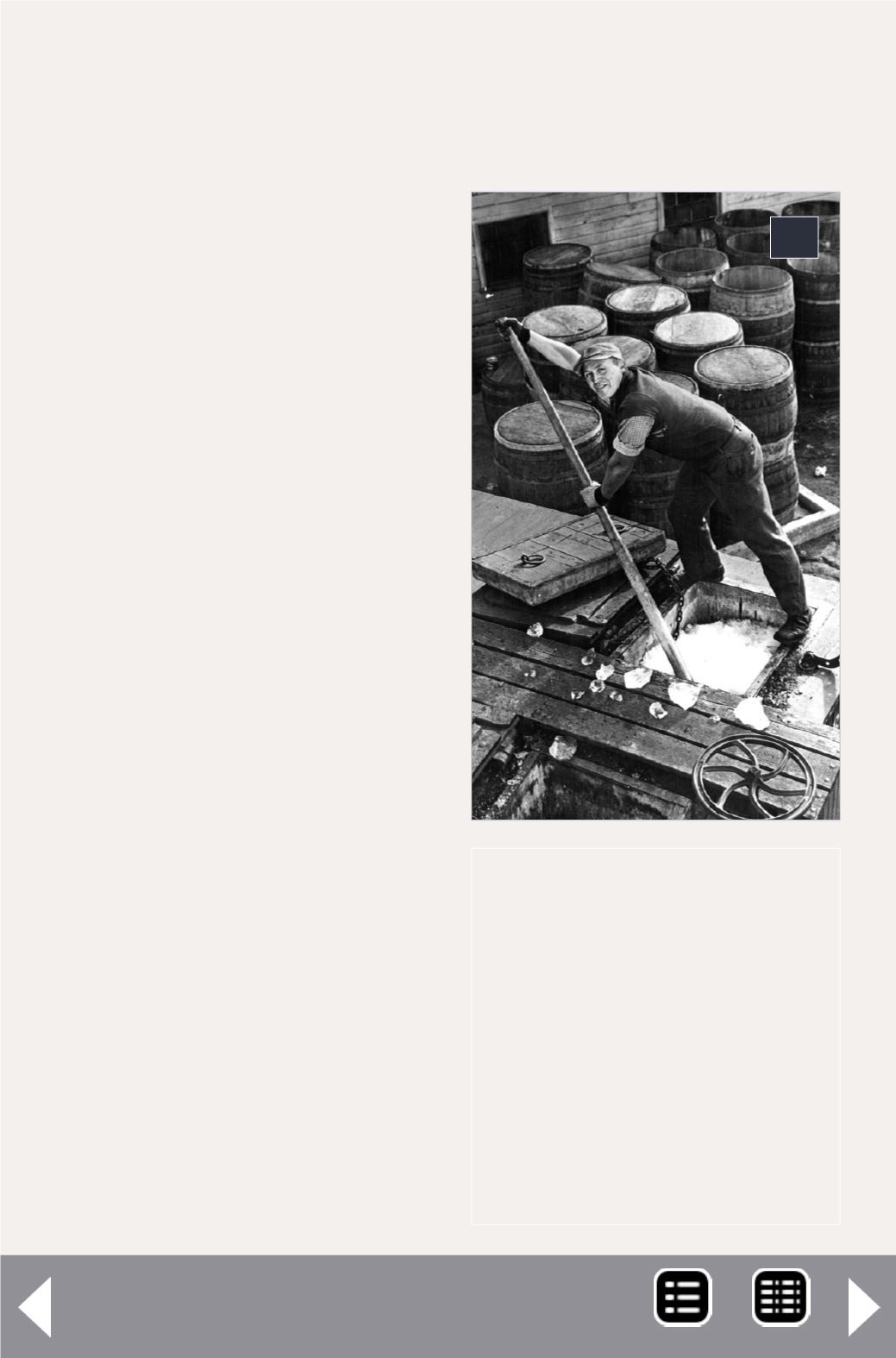

11: This workman is “bar-

ring” the ice in the bun-

ker. Ice size appears to be

“crushed.” This is a Union

Refrigerator Transit (URTX)

car. Note the separate

hatch plug, of canvas-cov-

ered wood construction,

lying atop the hatch cover.

– Arnold Menke collection.

11

It was up to the shipper to choose how they wanted the cars

set up for Protective Services, as the tariff term was. They

could choose (and pay) to have a car pre-iced, with ice bunkers

filled with ice prior to spotting

the car for loading. This would

ensure a cool car interior, and

would hasten the en-route

cooling. Or they could simply

have an un-iced empty spotted

at their dock. For shippers that

had their own precooling facili-

ties for produce, there was less

need for pre-icing.

Note the tariff language: cars

are pre-iced, and loads are

precooled, not the other way

around.

Then any loaded car was nor-

mally fully iced after being

picked up by the local freight.

This was called “initial icing.”

Whether any salt would be

added to the ice, to hasten

melting and increase heat

absorption, was up to the

shipper, for an additional fee.

The shipper also chose how

the in-transit icing was to be

conducted, for example to fill

the bunkers every 24 hours, or

to fill them at predetermined

MRH-Sep 2013