large space for model building; to have adequate storage for

modeling materials, parts, photos, and research materials; and

to be segregated into functional areas for things like assembly,

machining, soldering, etc. Just as important, and since I spend

a lot of time in my workshop, I wanted it to also be a bright,

relaxing, and pleasant place to work.

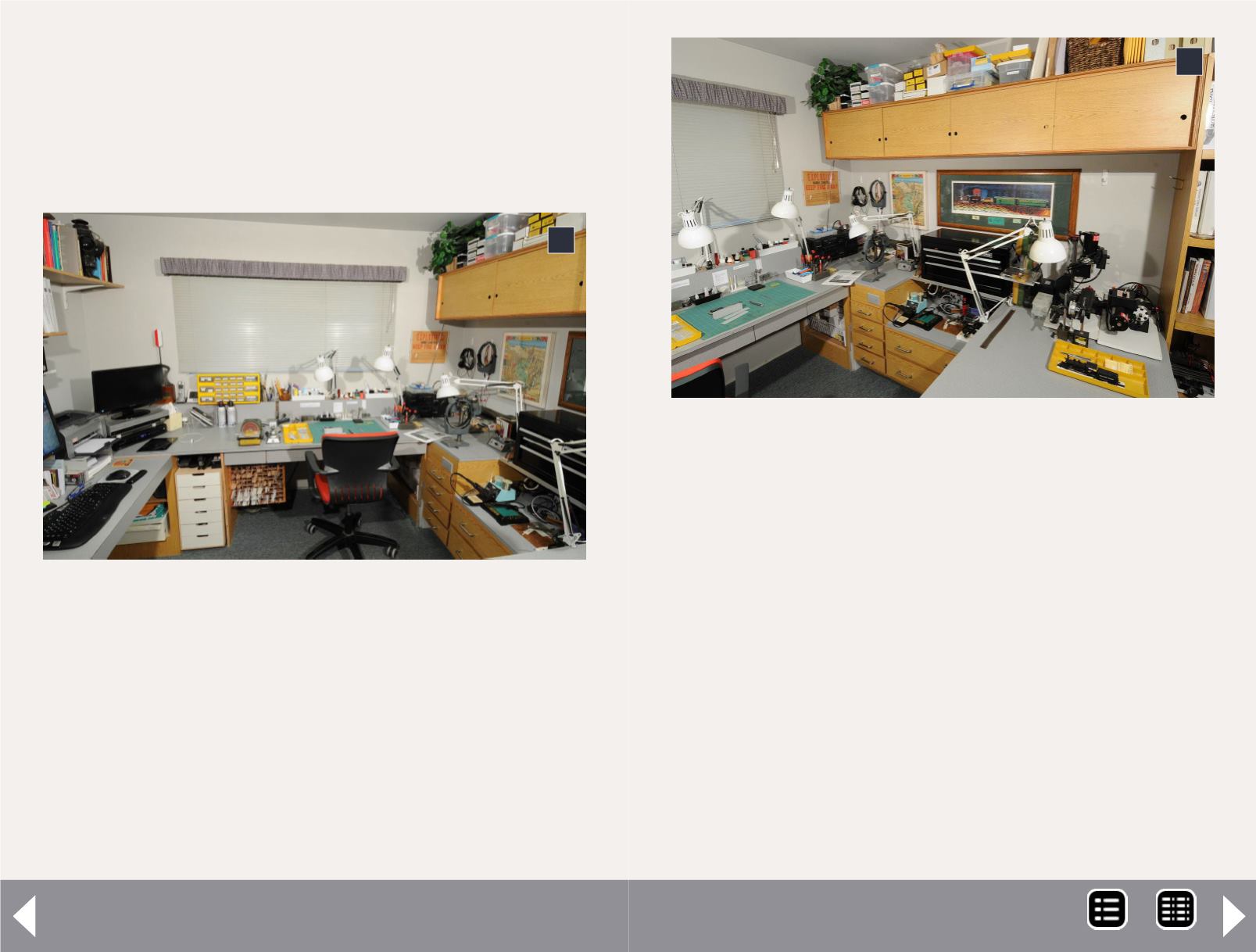

1: An 18”x24” green self-healing cutting mat defines

the main model building space. To the left of the mat

is a yellow drawer organizer for holding parts for my

current project, a vacuum base vise, and a power disc

sander. The white Ikea drawer unit on the far left pro-

vides space for pens, scratchpads, and other statio-

nery items. Along the back edge of the workbench is

a 7” high by 5” wide boxed-in shelf. This raised shelf

keeps items stored on it out of my working area. The

primary task light is also attached to the top shelf.

Electrical outlets along the face of it provide power for

the disc sander and other power tools.

1

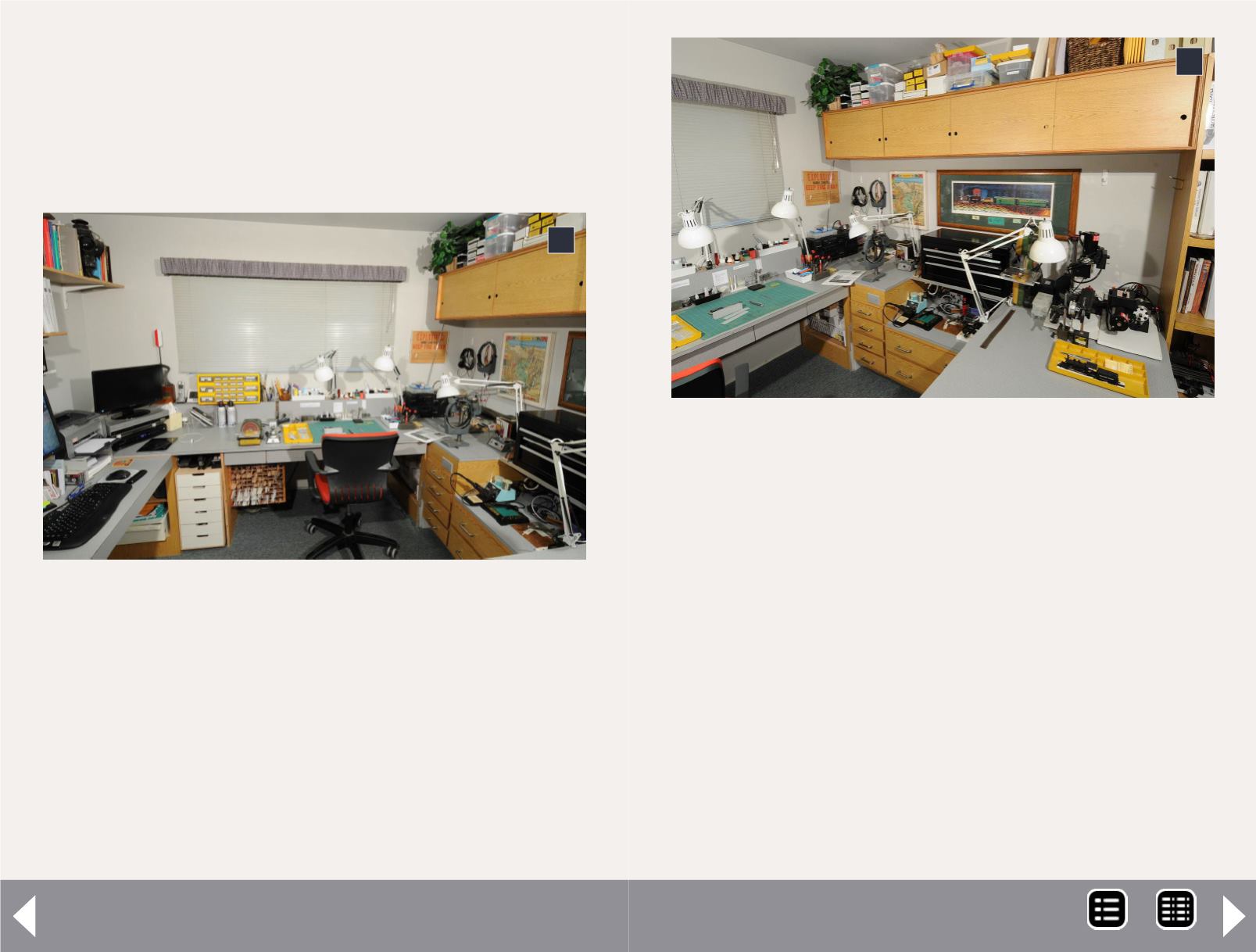

2: This is the view turning to the right from Photo 1. I am

right-handed so my precision drill press is immediately to

my right when I’m at the modeling bench. It has its own

task light. Under the drill press is a roll-out storage bin

which holds about 60 stockpiled resin freight car kits. The

lowered area to the right of the drill press was designed

for a full-size belt sander. (Lowering this area put the belt

sander table at the same elevation as my workbench.) I

eventually transferred that tool to my woodworking shed

and now use this area for a soldering station, resistance

soldering unit, and small table saw. The black 3-drawer

tool box on the shelf above these tools provides storage

for the mills, chucks, collets, etc. for my lathe and milling

machine. Those power tools, and a band saw are stored

to the right of this area. The lathe and milling machine are

mounted to boards so that they can be moved onto the

peninsula for use.

2

Getting Real Column - 2

MRH-Feb 2013