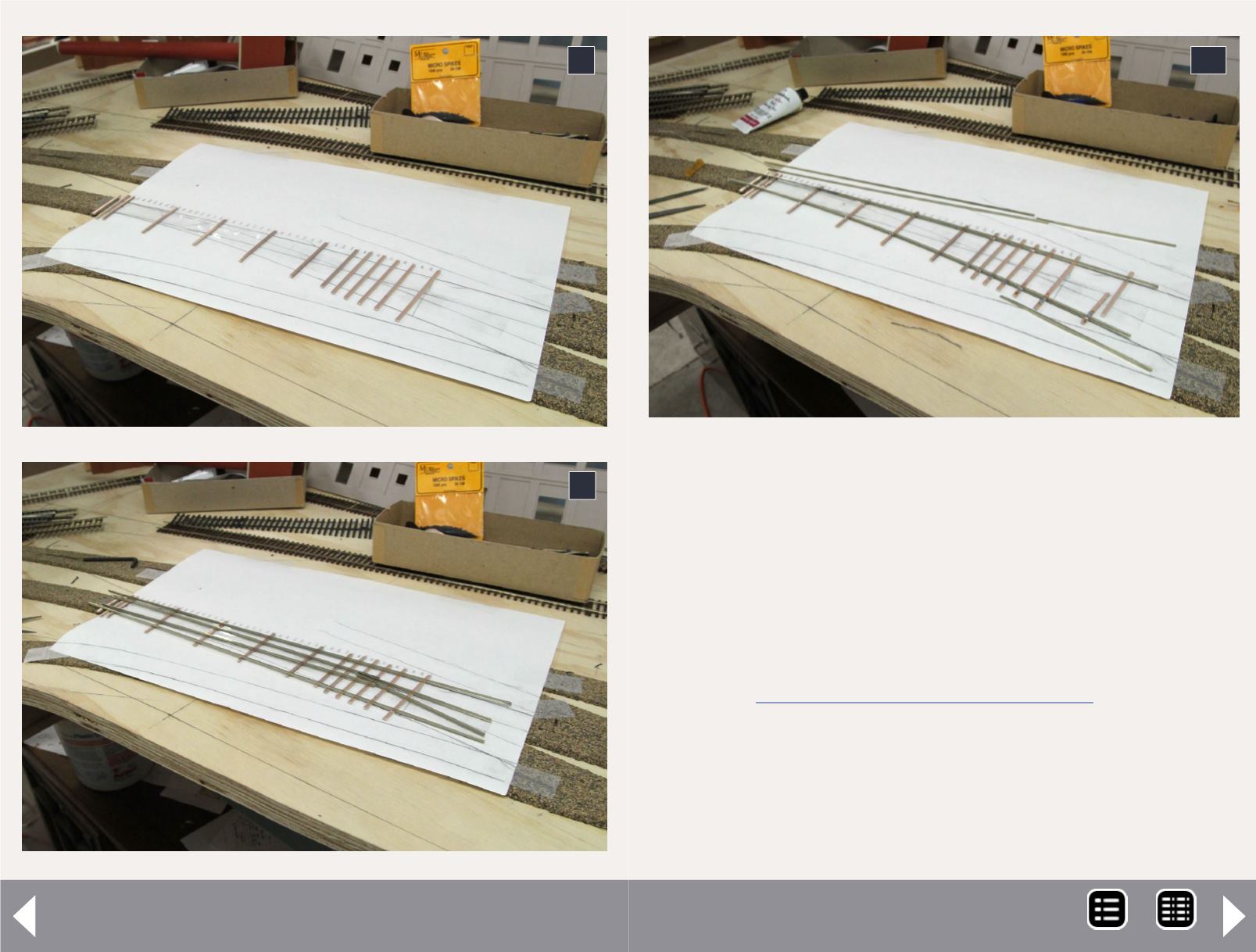

8

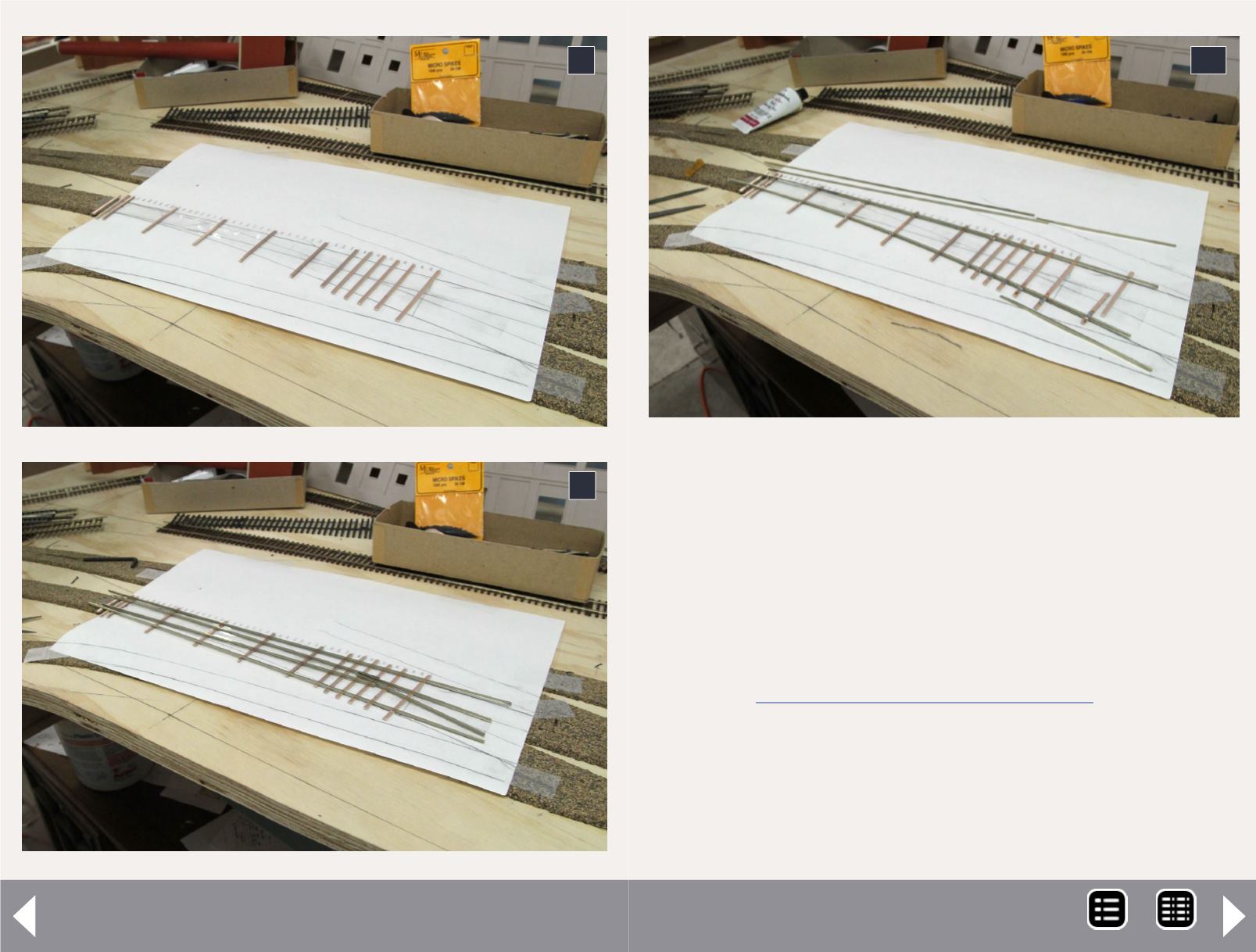

9

Up the Creek Column - 4

8: All the PC ties for the curved turnout are stuck in

place. Note how there are more ties where the frog will

be located. This helps stabilize this location and also

provide extra support when insulating gaps are cut in

the rails on either side of the frog.

9: Pieces of rail, cut out and ready for soldering to the

PC ties. I use a 5” disk / 1” belt benchtop sander to

“machine” the frog points, points, and stock rails. I

cover grinding the rails and assembling them in detail

in the companion video to the June 2012 Up the Creek

column

) where I

show how I build standard (straight leg) turnouts.

10: The first step in attaching the rails is soldering

the two stock rails in place. Be sure the notches cut

in them face the inside of the turnout where they’ll

accommodate the points and are lined up appropriately

for the location of the throwbar.

10

MRH-Feb 2013