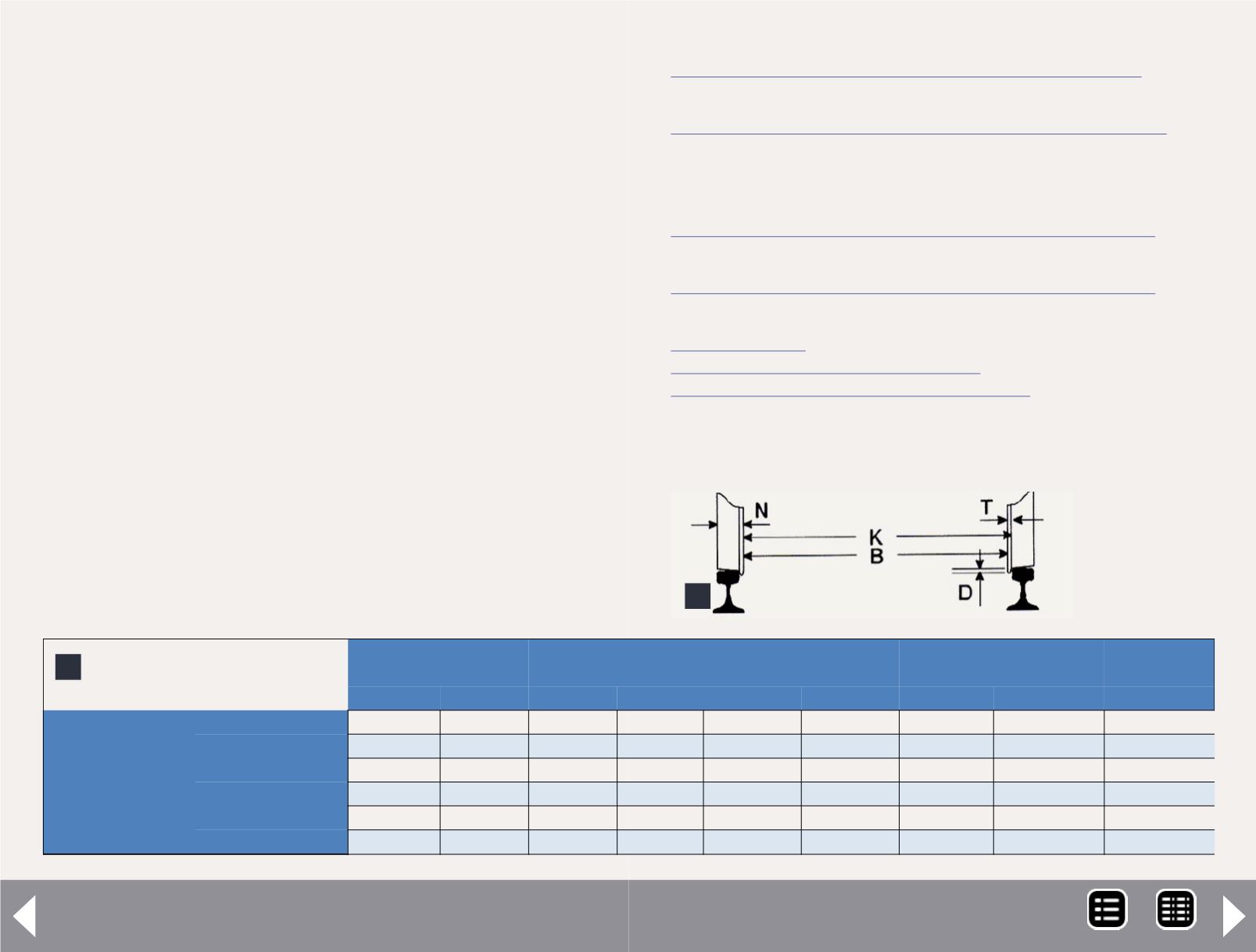

Back to Back (B) Tire Width (N) Flange Width (F)

Flange Depth(D)

Wheel

Check (K)

Min Max Min Max Min Max

Min Max

Max

Prototype inches

0.611 0.611 0.063 0.063 0.013 0.016 0.016 0.016

millimeters

15.52 15.52 1.610 1.610 0.340 0.400 0.400 0.400

Proto:87.1 inches

0.610 0.613 0.064 0.069 0.012 0.014 0.012 0.014 0.623

millimeters

15.48 15.55 1.620 1.750 0.310 0.350 0.310 0.350 15.84

Standard HO inches

0.566

0.108

0.030 0.028 0.028

millimeters

14.40

2.740

0.710 0.700 0.700

Proto:87 SIG

The catch: NMRA S-3.2 calls for a minimum flangeway width

of .050”, and allows a track gauge from .649” to .672”

(16.5mm to 17.1mm). If the tolerances are toward the wide

side, a Code 88 wheel can be a problem. Ideally, the Code 88

wheel would be used with a flangeway a little less than half

the tread width. S-3.2 is written for best operation with .110”

wide wheels.

A lot of manufactured track switches and crossovers don’t even

match up well with the NMRA RP-25 .110” wheels. The switch

dimensions and clearances don’t match the basic NMRA stan-

dard. So, even if track is gauged correctly, you can still encoun-

ter flangeways that are the wrong width and guard rails in the

wrong places. People using Micro Engineering switches and

switches built from Central Valley, P87 Stores, and Fast Tracks

materials report few problems, if any.

People who widen their track gauge on tight curves to accom-

modate long-wheelbase locomotives may find that wheels with

treads narrower than .110” drop between the rails and hang up

because the wheel assembly is narrower overall. People model-

ing bumpy, twisting track also need to be a little more careful.

Code 88 wheels won’t run well on Proto:87 track. That has an

even closer to prototype set of standards.

Questions, Answers & Tips - 2

3

The NMRA categorizes Code 88 wheels as “Fine:HO”:

Fine: HO track tolerances are closer to Proto:87 than standard HO:

Recommendations and standards

RP-25 wheel contour:

S-3 track standards:

Proto87:

2

MRH-Feb 2013