13: Hold own pieces in place.

13

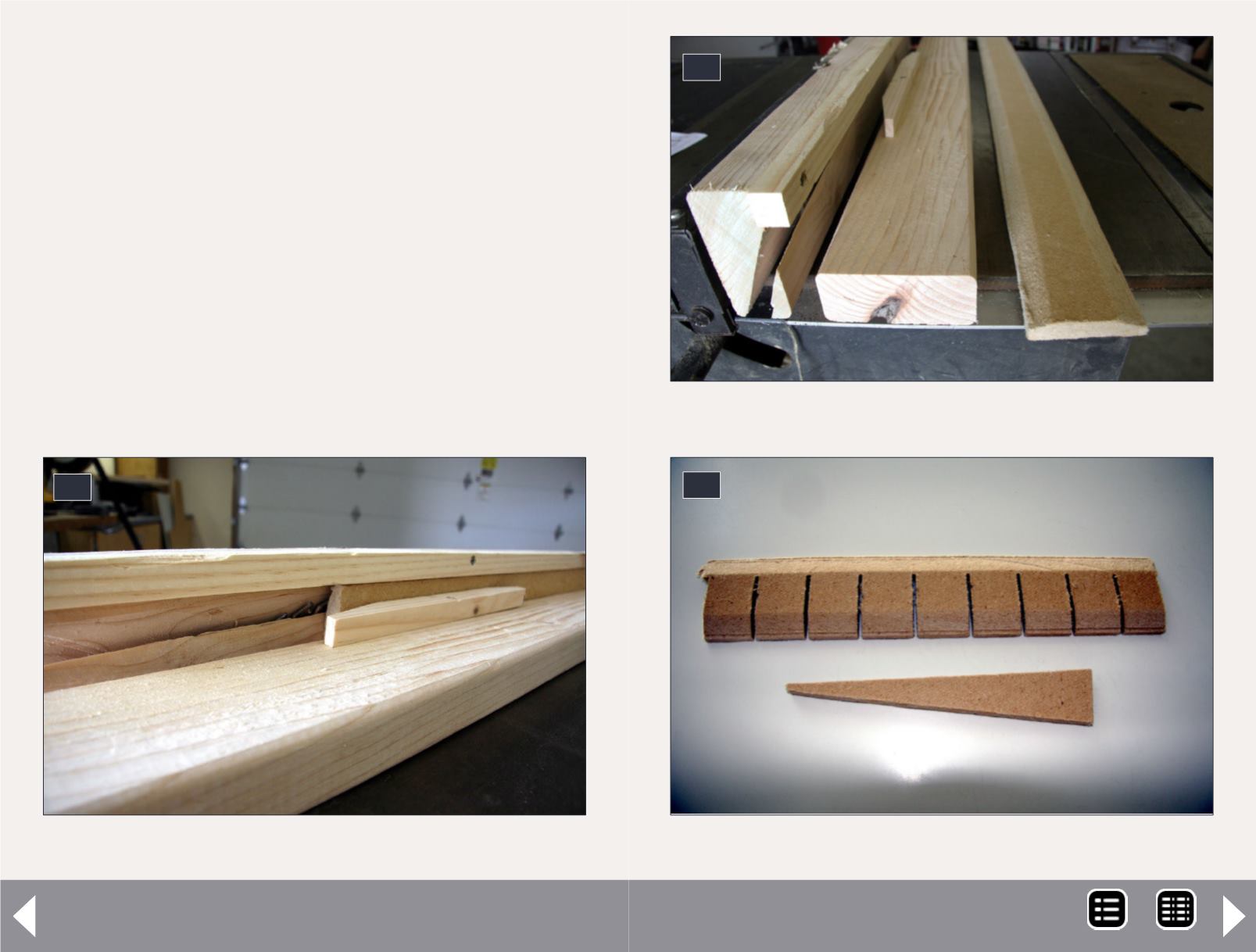

14: Roadbed cut for curving and switch insert.

14

Getting Real column - 6

table. This keeps the work in accurate position and provides

protection for the operator (12).

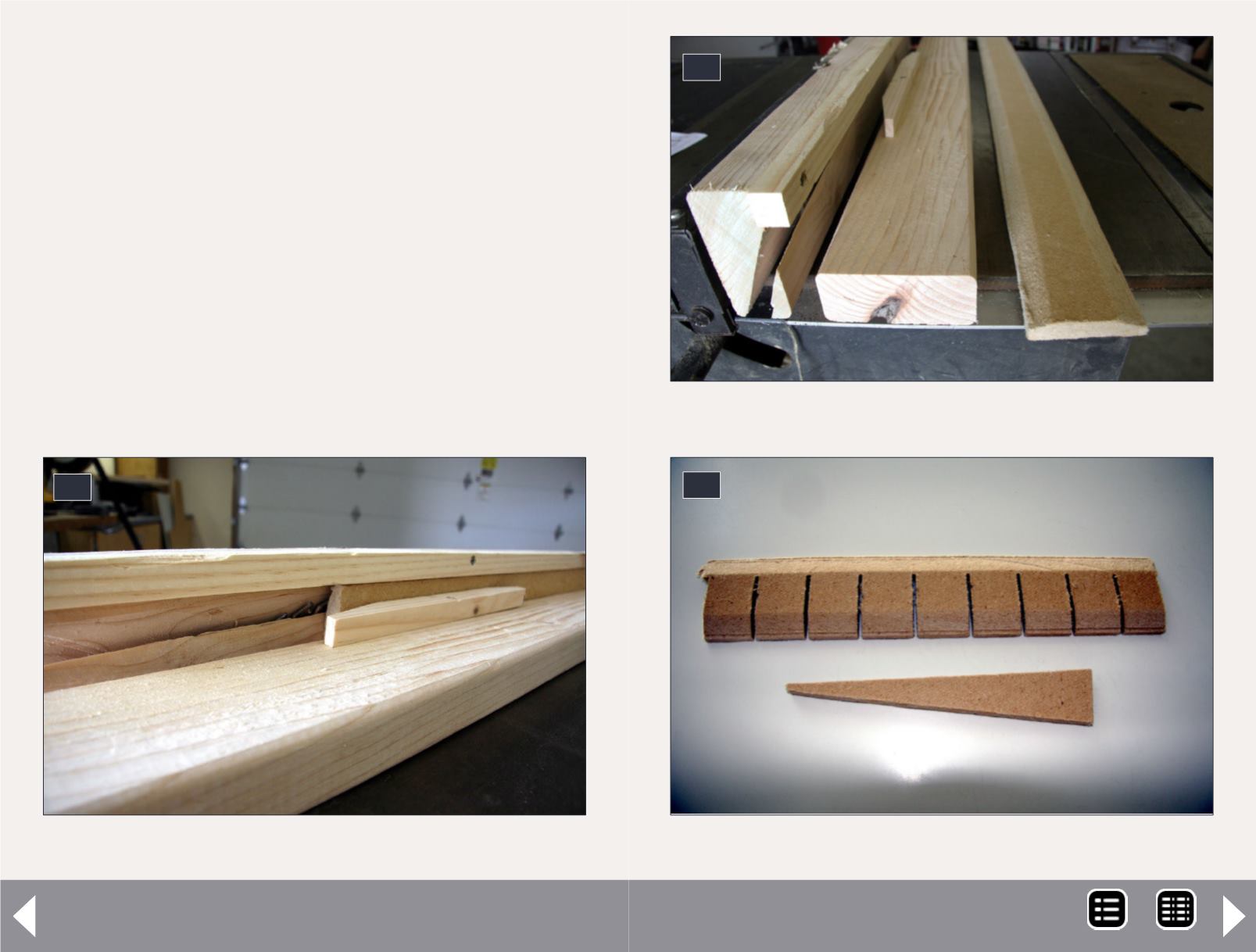

A completed length of finished roadbed is shown, on the saw

table to the right of cutting jig, in figure 13. To lay curved sec-

tions, slots are cut about ¾ of the way through the roadbed to

allow it to bend. The spacing for the slots is roughly the radius

of the curve divided by 12. For a 30” radius R/12 = 30/12 = 2.5”

spacing between the slots. Lay the slots on the inside of the

curve so that the slots tend to close as the roadbed is bent.

A word of caution, cutting the Celotex generates a lot of fine

dust! Work outside if you can. I call it clean dust, because it

blows down and vacuums up readily. Save half a shopping bag

full of the dust; it will be useful later!

For switches, a wedge-shaped section of Celotex is cut to

match the number of the switch. For example, the wedge

12: Note the small amount of exposed blade.

12

MRH-Jan 2013