ductwork for the two HVAC systems that are above the ceiling in

the hallway. He also was the main carpenter on this project, doing

the stud walls, framing and finishing the woodwork.

Now it was time to hang the T-bar ceiling. Again we had some

good luck. Another hobbyist who does this work as a profes-

sion volunteered his time, and the T-bar went in quickly. As

this was being done, others erected a skyboard that wrapped

around the entire room matching the one at the old location.

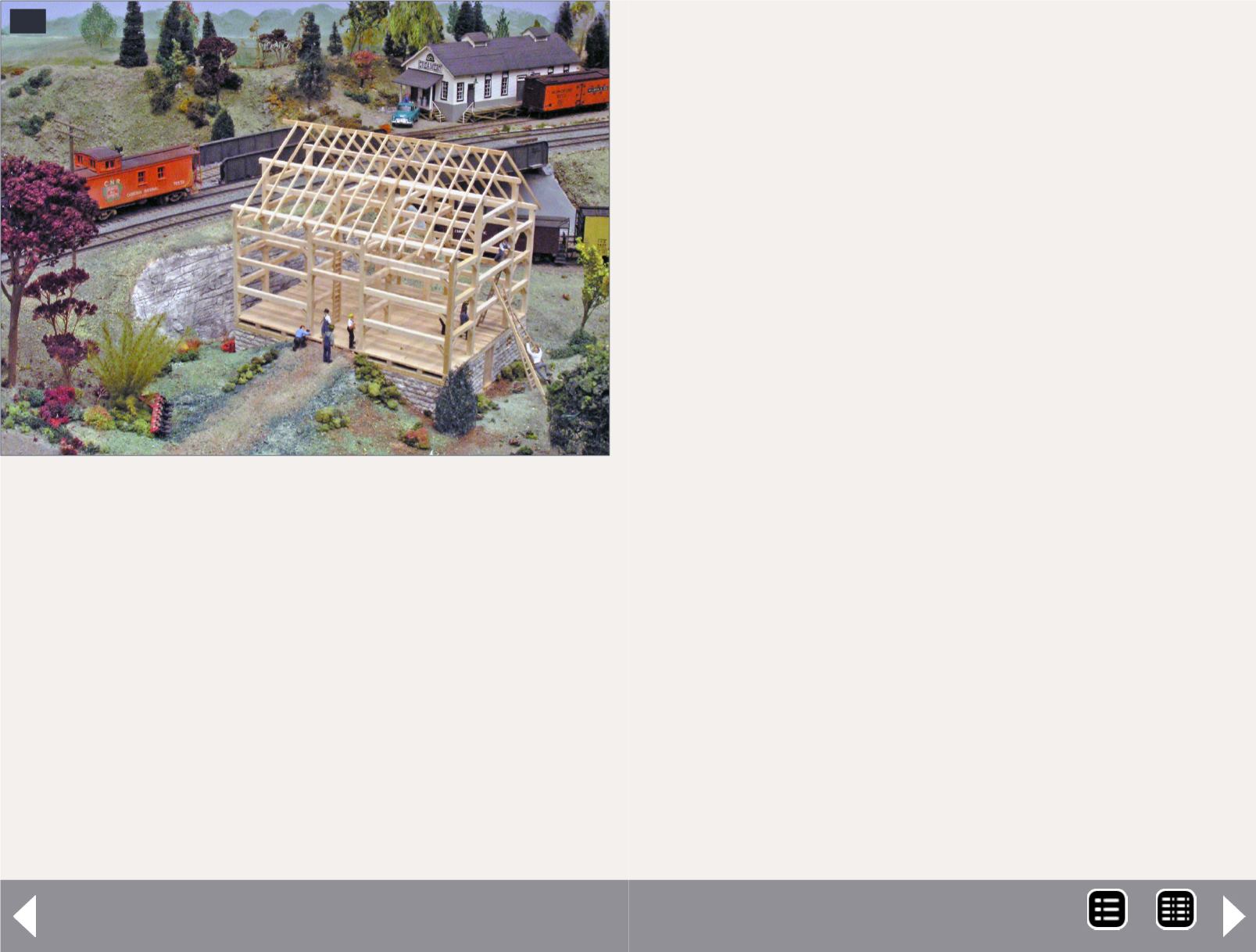

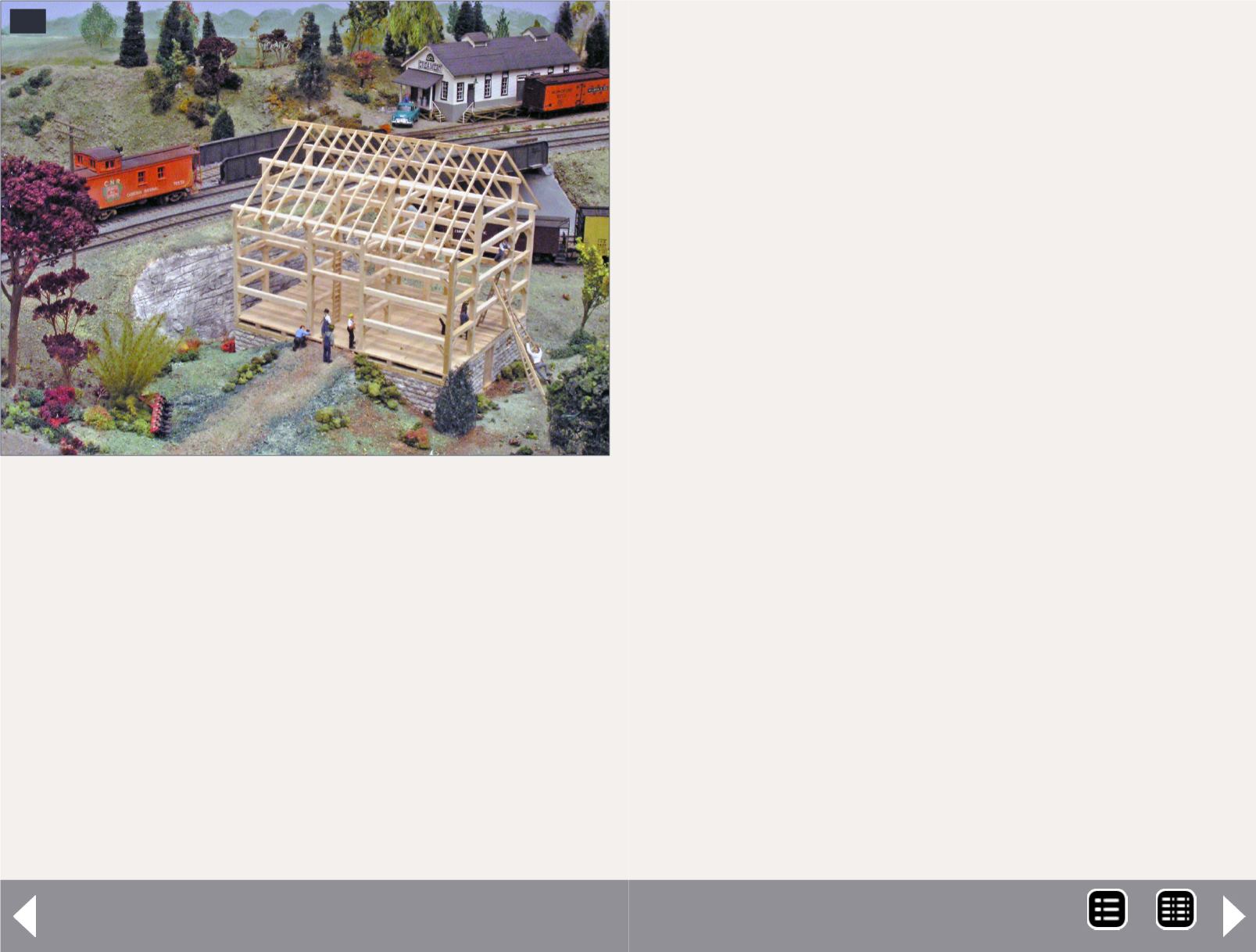

13. Continuing the Mennonite theme, there is a barn-

raising just down the road from the meeting house. In

behind, one of Chuck’s scratchbuilt CNR cabooses

brings up the rear of a freight, which has just passed a

local creamery.

13

Thought had been given to operating the layout. At the old

location, the central control tower gave a good view of the

whole layout. In this place, all the operators would be on the

balcony at one end of the layout. The solution to viewing areas

close up was to mount cameras in the ceiling, feeding moni-

tors mounted above each control panel. Chuck planned this

by using the ceiling at Aberfoyle as a grid to plot positions on

the layout. The new ceiling became the new grid. This made it

possible to install the lighting fixtures and the cameras while

the room was empty, much easier than trying to work over

the layout later. It also allowed Gwen to paint the backdrop at

that time, knowing the scenes would match up with the layout

when it was installed. While all of this was going on, other vol-

unteers framed up the balcony.

By mid-September the room was complete. It was time to

bring the layout over. This was done in four days over two

weekends. Each trip took roughly three hours. It was grunt

work, but went efficiently, thanks to the previous planning.

Eleven round trips involving 51 layout pieces got the job done.

Now the rebuilding could begin.

Putting the puzzle back together

As the layout pieces came off the truck, they were placed in

roughly the position where they would be re-erected. The

pieces closest to the skyboard were set first. This required

going through the stack of legs, to identify which went where.

As each section was set on its legs, it was attached to its neigh-

bor with gussets joining the sawed roadbed back together.

Then the pieces of rail that had been removed were re-

installed. Care was taken to make sure each section was level,

and joined the adjacent pieces exactly. Track switches were

Aberfoyle Junction - 10

MRH-Dec 2014