necessity and desperation inspired yet another approach. I had

been working on a model waterfront pier, and realized that the

piling reinforcement often found with hemp rope might work

here. I had a spool of very fine, strong thread on hand, and

decided that pilings and axle gears are close enough!

After removing and cleaning the gear, I verified that the crack

had not progressed to the center of the gear. The axle gears

are made of a slippery plastic, much like Delrin which typically

does not glue well at all. I applied a thin coat of CA glue sur-

rounding the end of each side of the gear and wound several

turns of thread through the glue. It is imperative that you make

this as thin and strong as possible, as clearances in the motor

truck are tight. So far, the reassembled trucks have worked

fine and the crack did not progress to the gears.

Considering that power might be at a premium in this loco,

other variations were tried to reduce the current draw. First,

the motor and truck gears were removed completely, leaving

only the two freely turning axles in one truck. This obviously

reduced the tractive force available, but also halved the total

power. On another truck I removed the intermediary gears

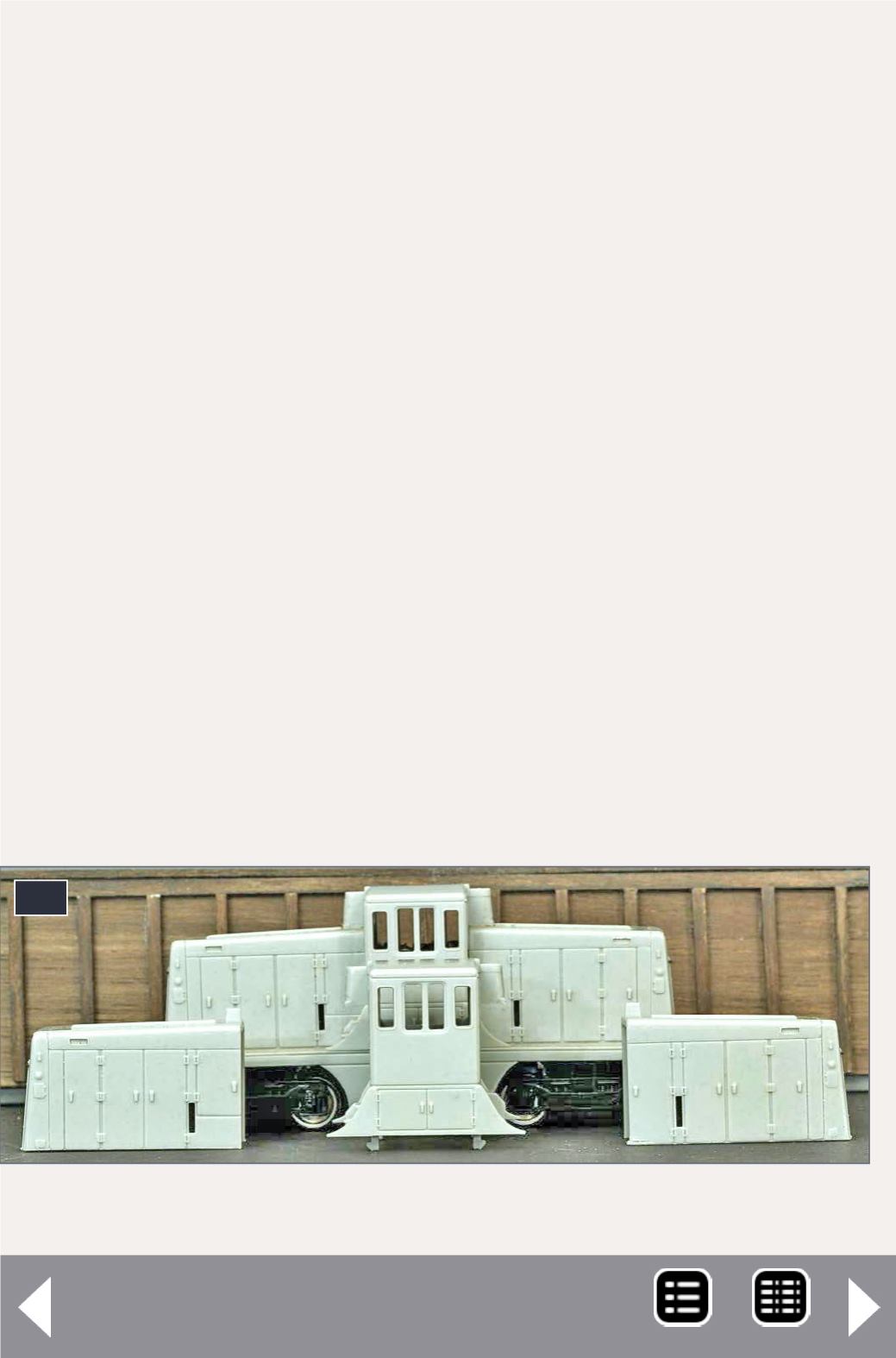

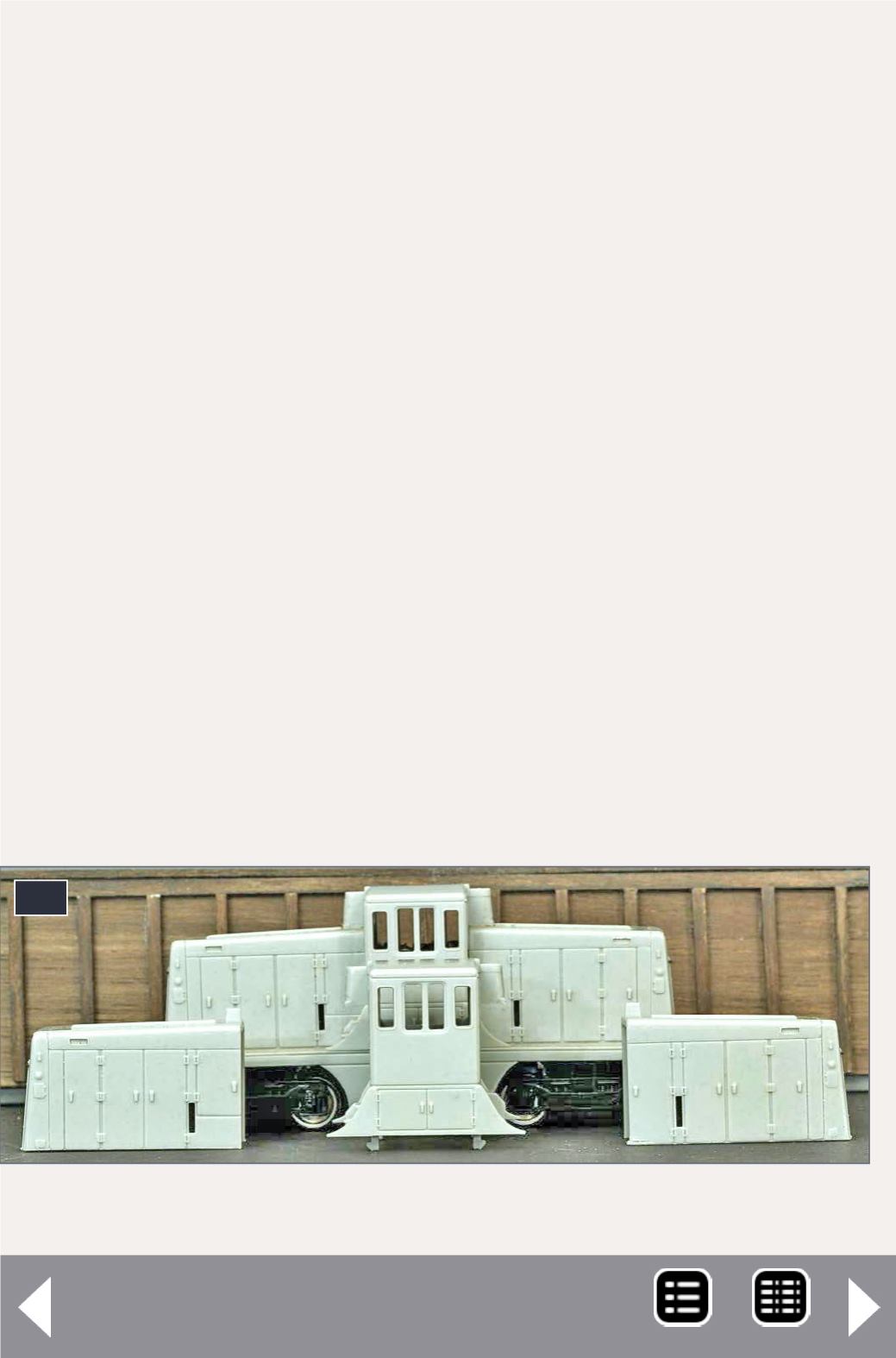

17. Bachmann 44-ton switcher, in sections.

17

Battery-powered models - 8

MRH-Nov 2014