STEP 1: Creating a bending template

Continued ...

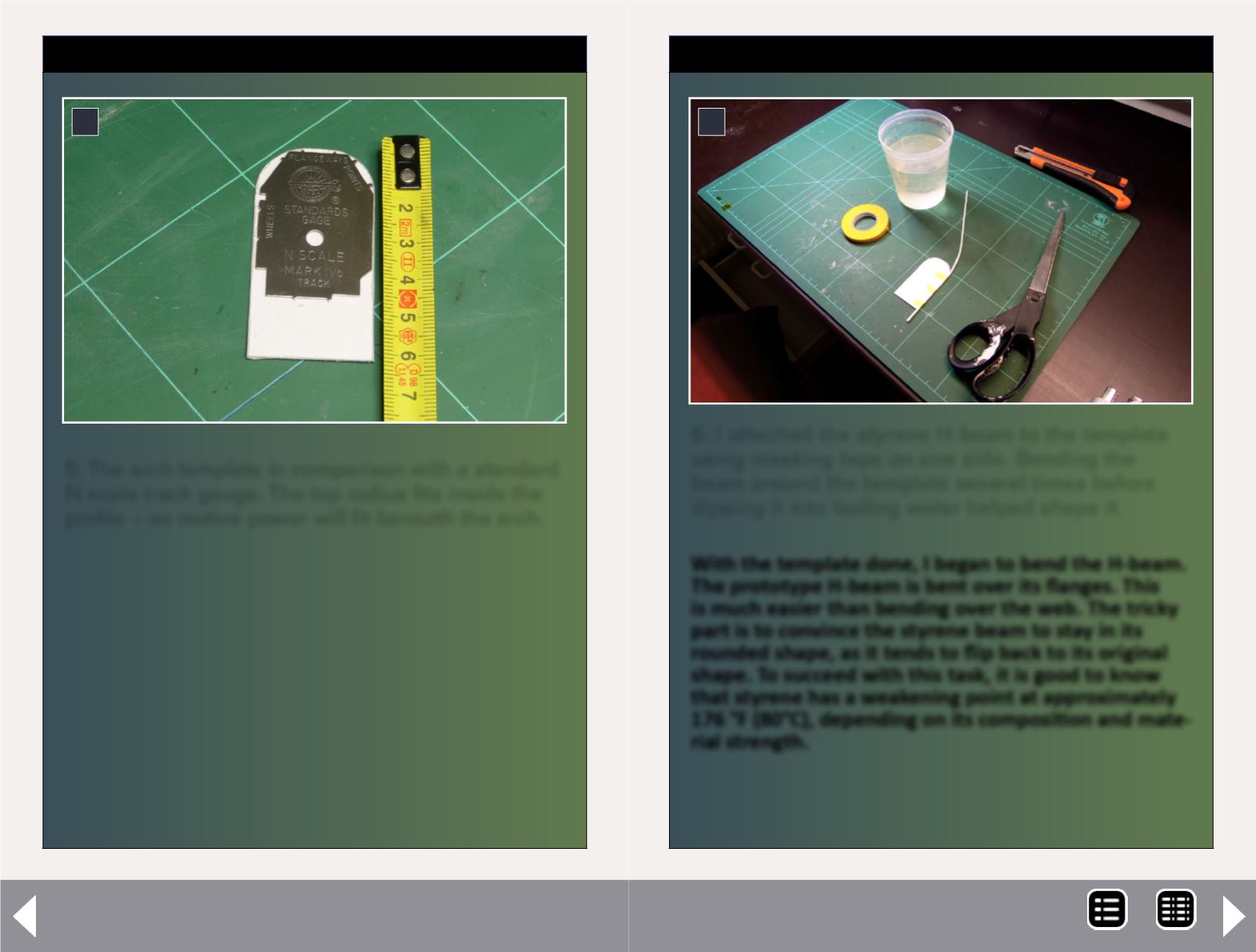

5. The arch template in comparison with a standard

N scale track gauge. The top radius fits inside the

profile – so motive power will fit beneath the arch.

5

Turntable bridge - 4

STEP 2: Pumping iron – bending styrene

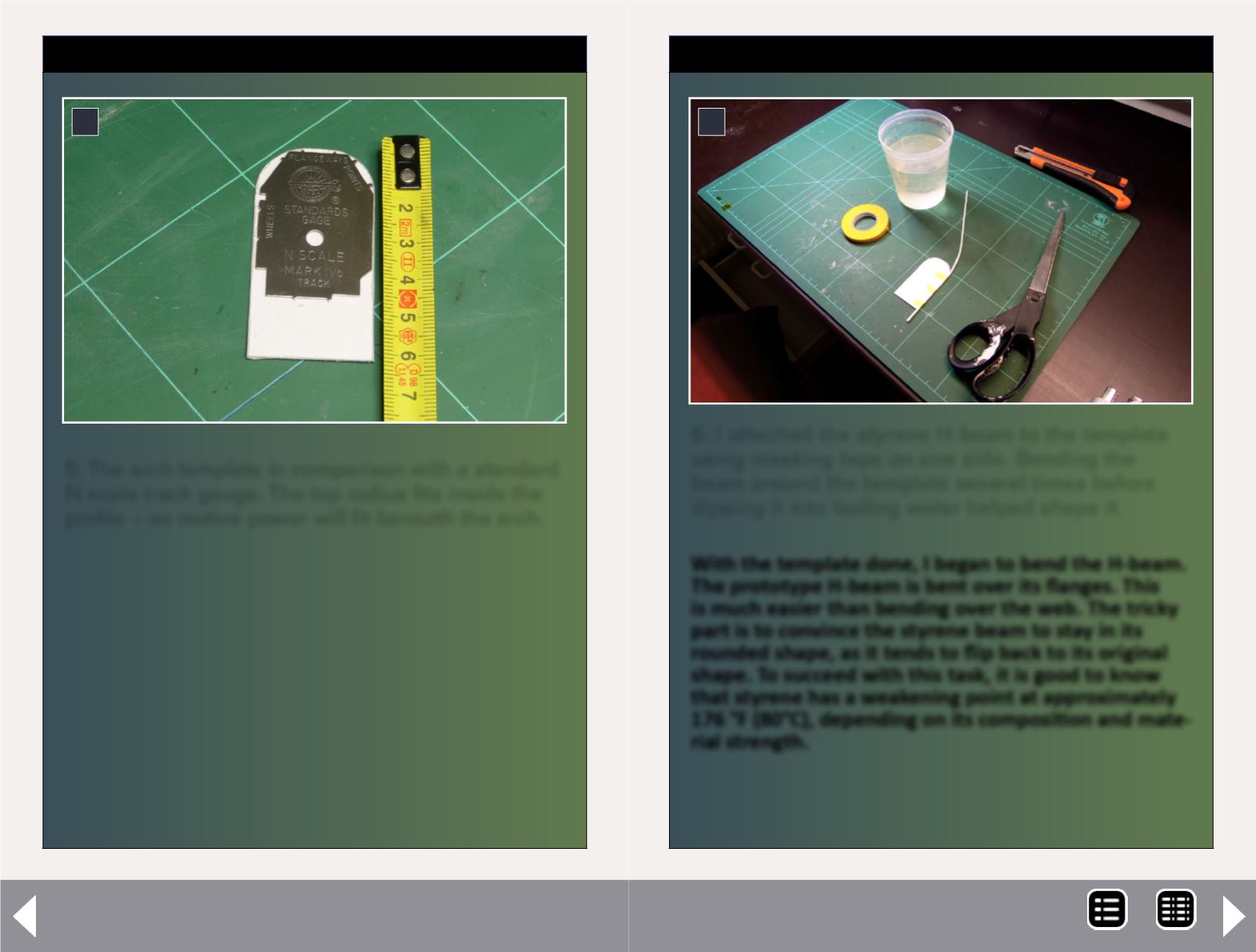

6. I attached the styrene H-beam to the template

using masking tape on one side. Bending the

beam around the template several times before

dipping it into boiling water helped shape it.

6

With the template done, I began to bend the H-beam.

The prototype H-beam is bent over its flanges. This

is much easier than bending over the web. The tricky

part is to convince the styrene beam to stay in its

rounded shape, as it tends to flip back to its original

shape. To succeed with this task, it is good to know

that styrene has a weakening point at approximately

176 °F (80°C), depending on its composition and mate-

rial strength.

MRH-Sep 2014