build it using open steel construction, like the prototype, and

with nailing strips.

Based on the measurements of 9” H-beams taken at the site

of the Jollar tipple, I used 1/8” Evergreen styrene H-beams

for the steel work. I added gussets from .020” sheet styrene

to the corners and at the junctions of the H-beams, which

strengthened the joints.

The cross-bracing in panel is 1/8” Evergreen styrene with

.020” plates at the junction. For those center plates, I added

Archer rivet decals for the X. The nailing strips are scale 2” x

8” Evergreen styrene strips glued in place at 8’ intervals.

2

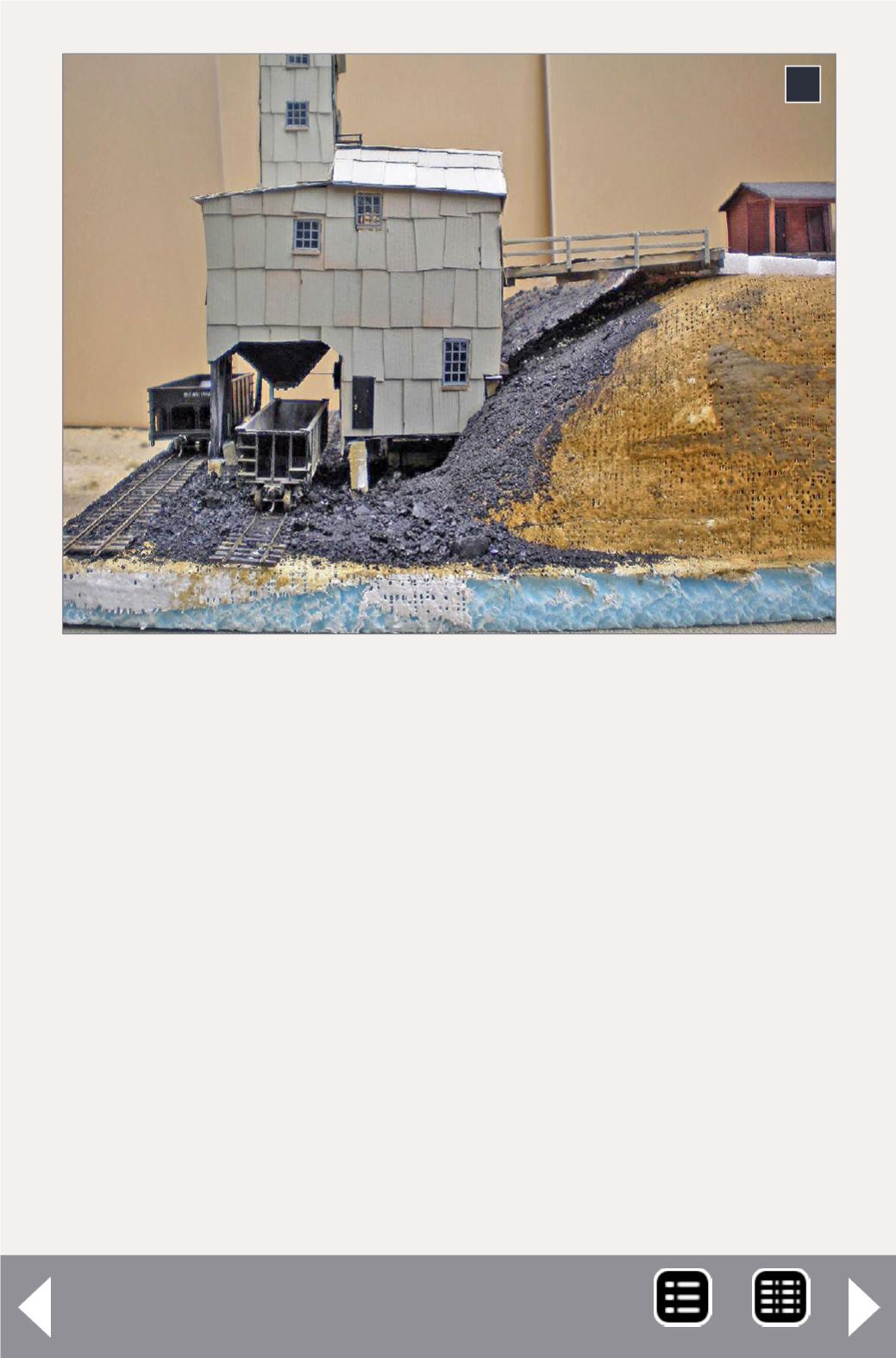

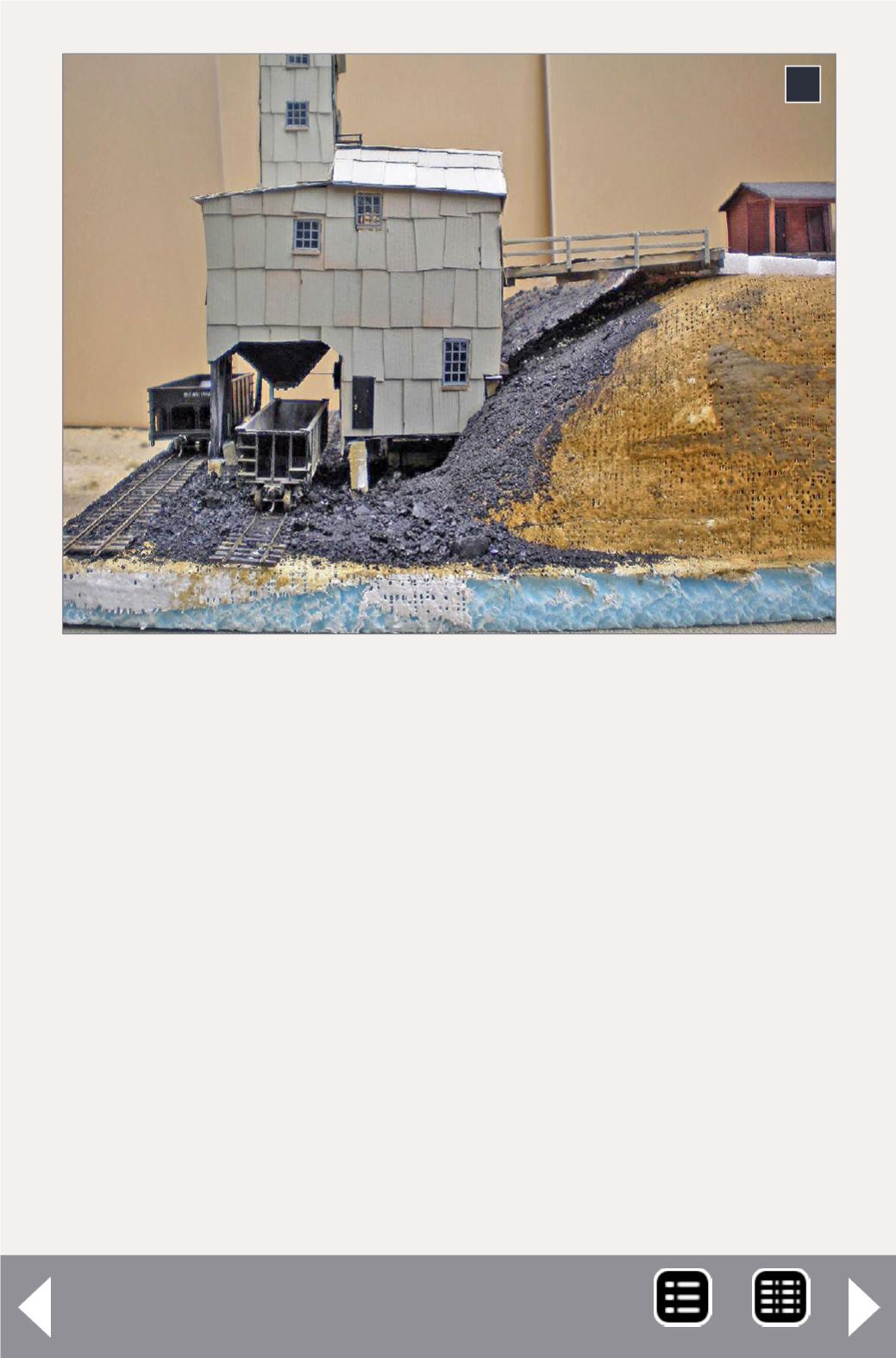

2. West side of the miller tipple showing the ramp to the

top of the embankment and the loading chute under the

main tipple.