Questions, Answers & Tips - 2

“Being the tightwad that I am, I don’t like paying $15+shipping for

a chisel. I have had excellent results with a good old X-Acto #17

chisel blade,” said Ken Rickman. “The key to getting good results is

to have it sharp! … I lay a sheet of 600 grit wet/dry sandpaper on

a flat surface, and hone the blade, back first to flatten it, then the

bevel. A drop of water or light oil like kerosene helps a lot. With

this technique, I’ve been using the same chisel blade for many

months now, maybe years. Hand sharpening does tend to round

the corners a little, which is good for preventing gouging.”

A good sharpening stone also works.

“If I needed to get into a really tight space,” Ken said, “I’d care-

fully grind away part of the width of the blade with a Dremel

tool, or buy a narrower blade. After shaping, I’d re-sharpen the

1

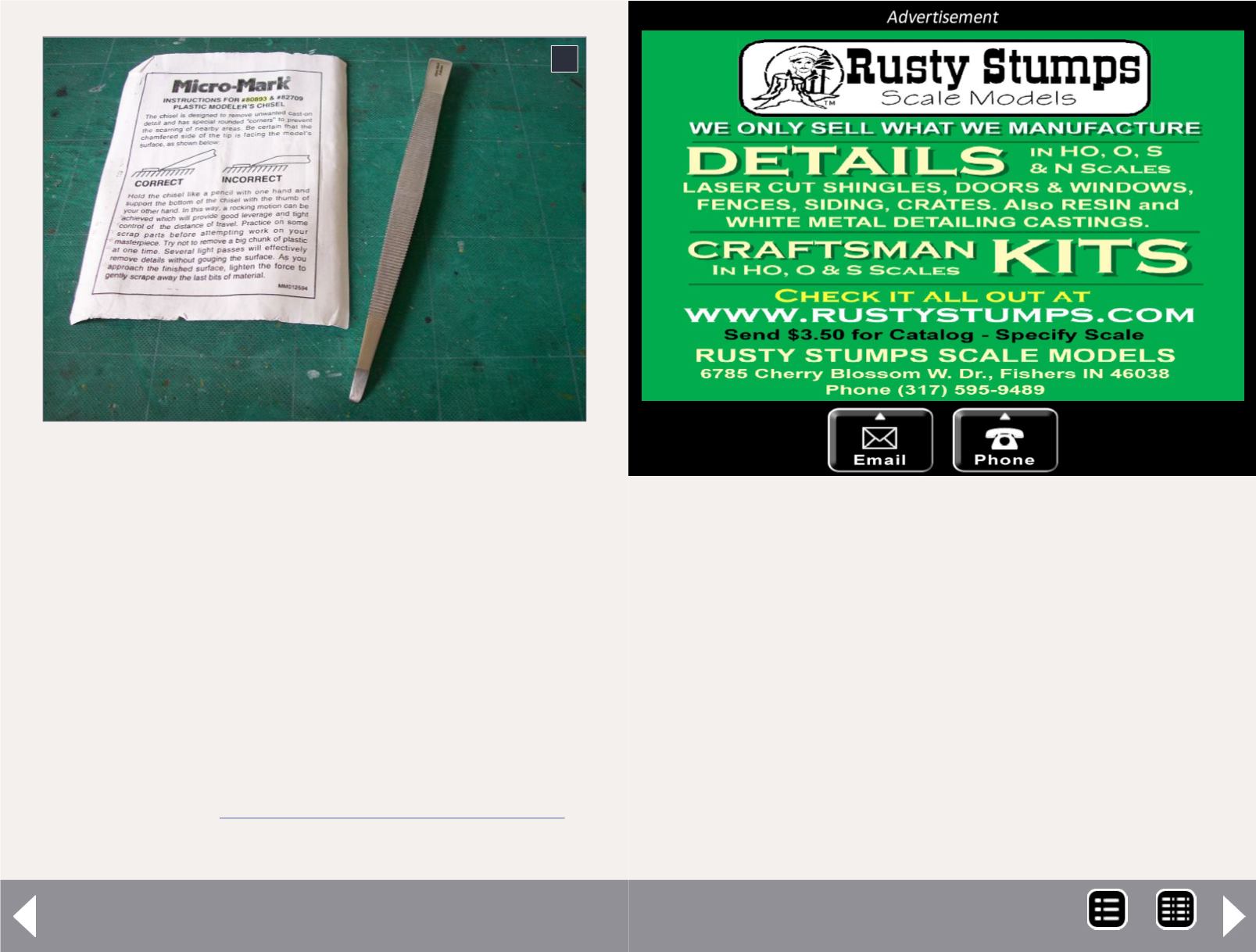

1. The 4mm Micro-Mark #80893, complete with advice

for use.

Several readers, including Choo Chuck, Brent, and OKGraeme,

report success with Micro-Mark “plastic modeler’s chisels.”

The 4mm one is part #80893 and the 2mm one is part number

82709. Each lists for $20.55.

“Just make sure you use it the right way around [1]. It seems

counter-intuitive, but you use it with the ground side down.

That way, if you slip it goes up and away from the surface

rather than digging into it,” Brent explained.

OKGraeme also uses sprue cutters. “I trim off most of the mass

first with #11 blades, then finish with the sprue cutters … I

use the B&B Hobby Supplies sprue cutters available through

Intermountain.” See

.

No matter which tool is used, a dull tool can be dangerous.

MRH-Aug 2014