Lite and Narrow Column - 6

pillars sit on top of both concrete walls at the ends of the lower

wall. They are positioned 3’ in from the right end of the tall wall,

and line up with the two pillars on the front wall. For these three

molds, I constructed boxes from scale 12” x 12” lumber stacked

two-high, to get the proper thickness. Making sure they were

square and dry, I glued them onto scrap styrene sheet with air-

plane canopy glue. When dry, I glued scale 1”x 12” boards into

the bottom of the boxes to simulate the concrete forms.

The four pillars were made by building a box using the 12” x 12”

scale lumber 13’ long and 2’ wide. I also glued this to the scrap sty-

rene. The last pillars to be cast were 18” square and 2’ and 3’ long.

I needed two 2’ pillars and four 3’ pillars. Using the same tech-

niques as with the large pillars, I tried to cast them individually. It

didn’t work. I built a long box, 18” wide, of scale 6” x 18” lumber,

and glued it to the styrene. The most difficult mold to build was

for the sand pit. This is a box 11’ square with a center opening.

The outside walls were constructed of 12” x 24” scale lumber,

24” tall, and with an inside dimension of 11”. Make sure the

angles are square, and glue the box to the scrap styrene. Take

a 6” x 16” piece of scale lumber and lay the 16” flat, butting up

against outside wall. Then build the inner wall from the 12” x

24” scale lumber using the 16” board as a spacer. Glue the inner

wall into place and remove the spacer board. Using Hydrocal,

I poured all of the castings and let them dry. For the small col-

umns, I removed them from the mold and used a very fine-

tooth saw to cut them to length. I painted all the columns and

walls weathered concrete.

Diorama base

I began construction of the diorama base with ¾” foam board

cut to 24½” x 16”. This can be expanded later, as needed. I cut

and temporarily attached two lengths of Code 55 flex track to

the foam board to get the proper spacing.

I glued the walls and columns in place with white scenery glue,

according to the footprint plan. Finally, I adjusted and marked

the track spacing.

6

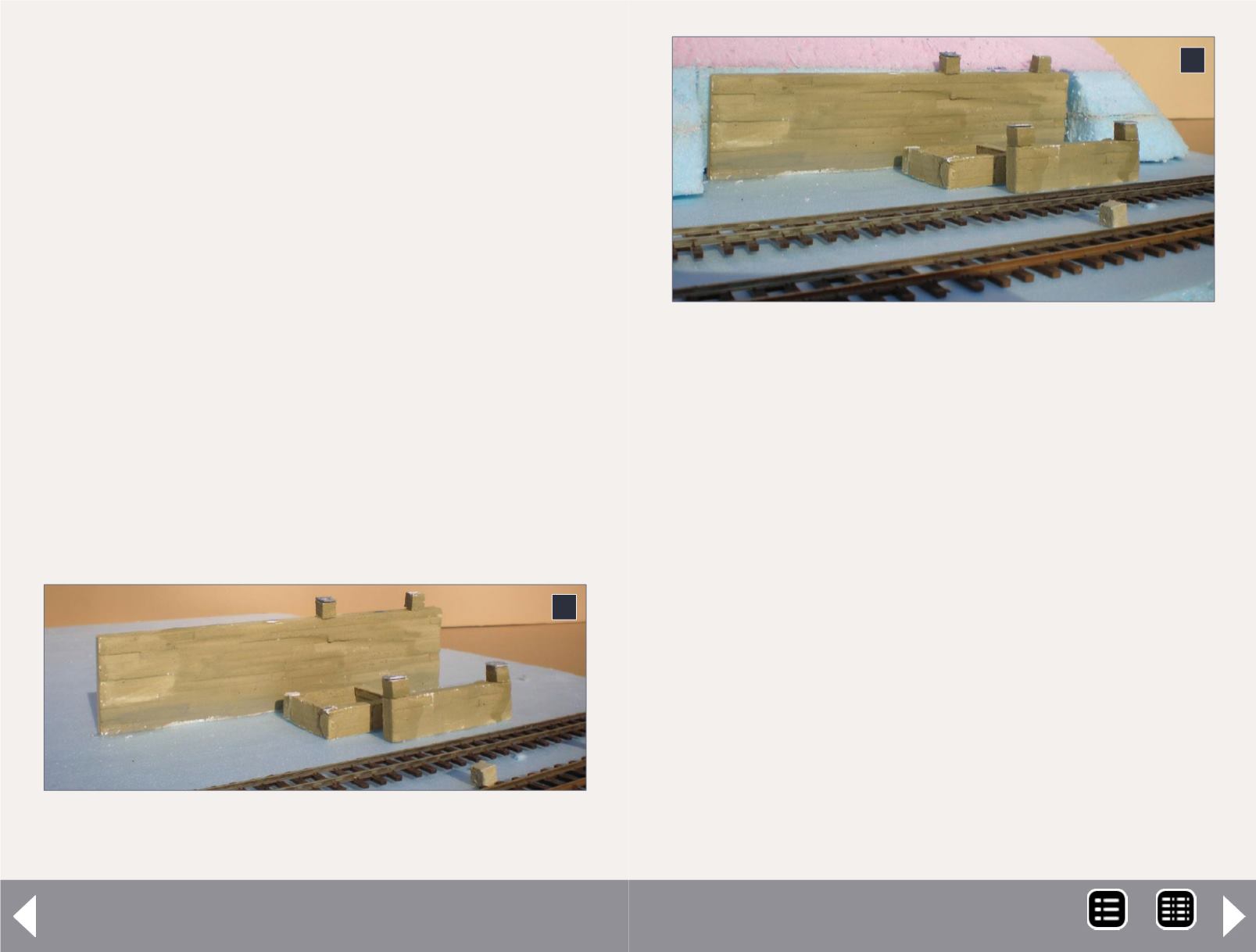

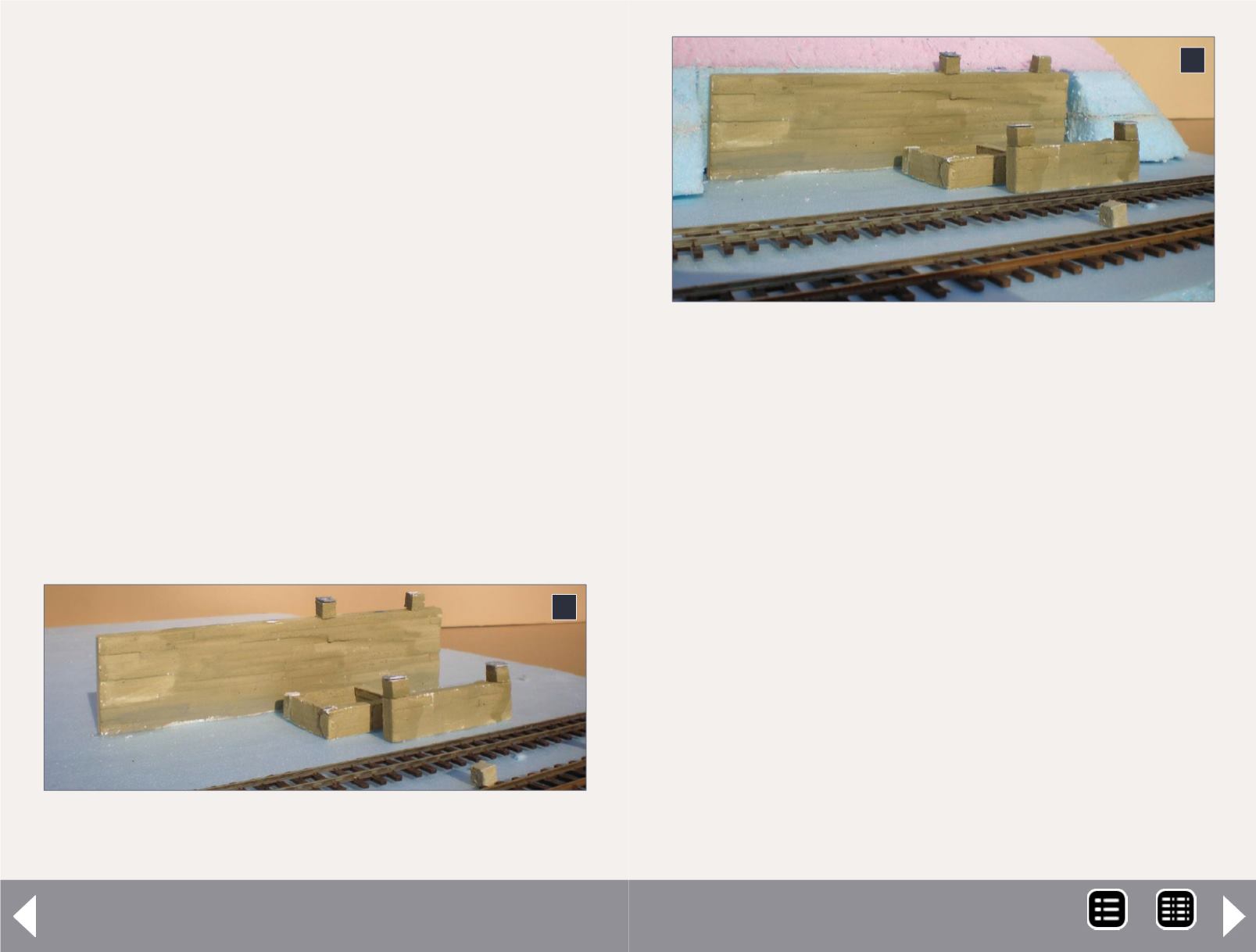

6. Retaining walls and support piers glued in place on the

Styrofoam base according to the plan.

7

7. Hillside built up to mine level using various sizes of

Styrofoam sheets. Track is laid temporarily to check

clearances.

MRH-Jun 2014