2

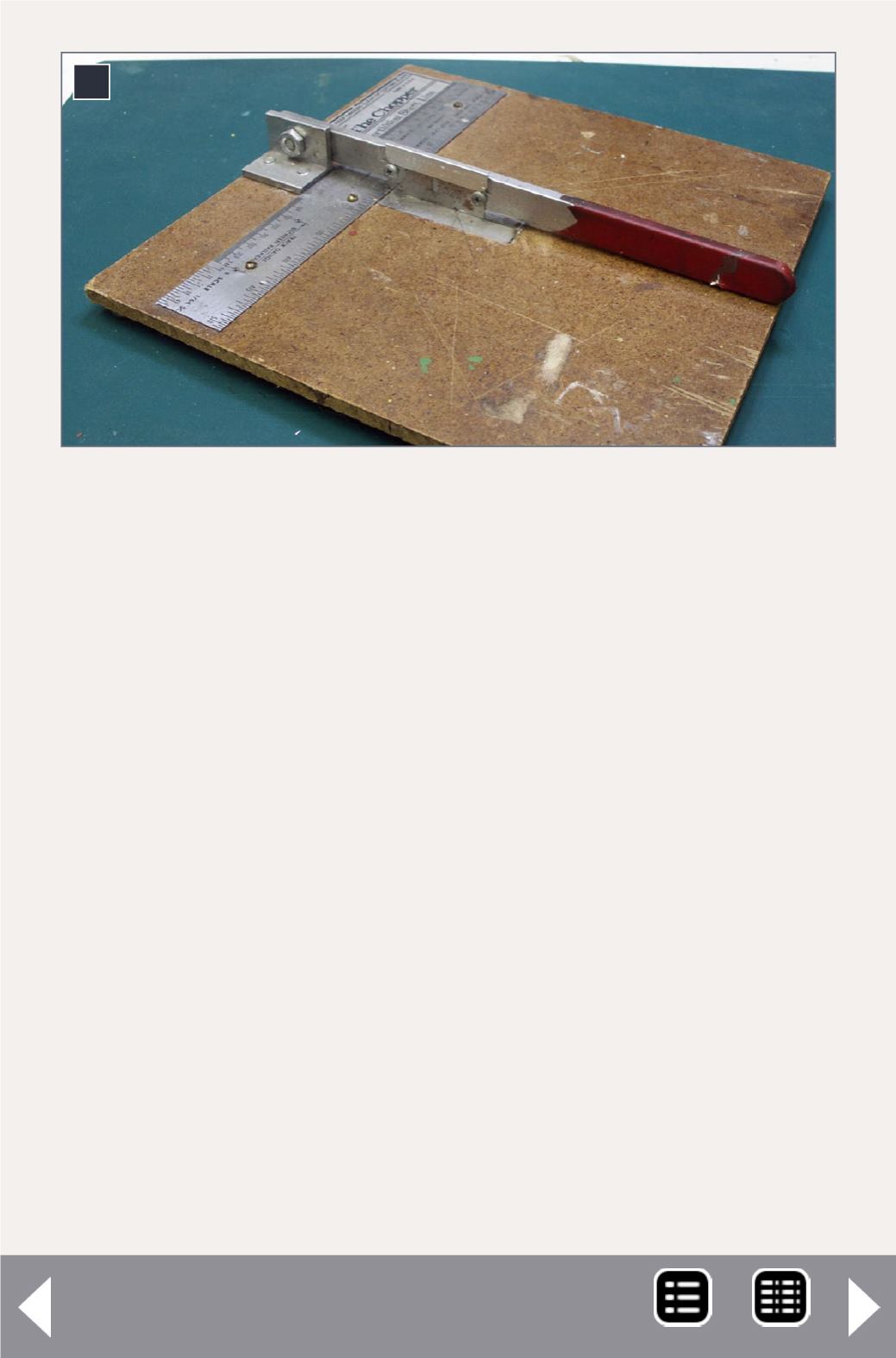

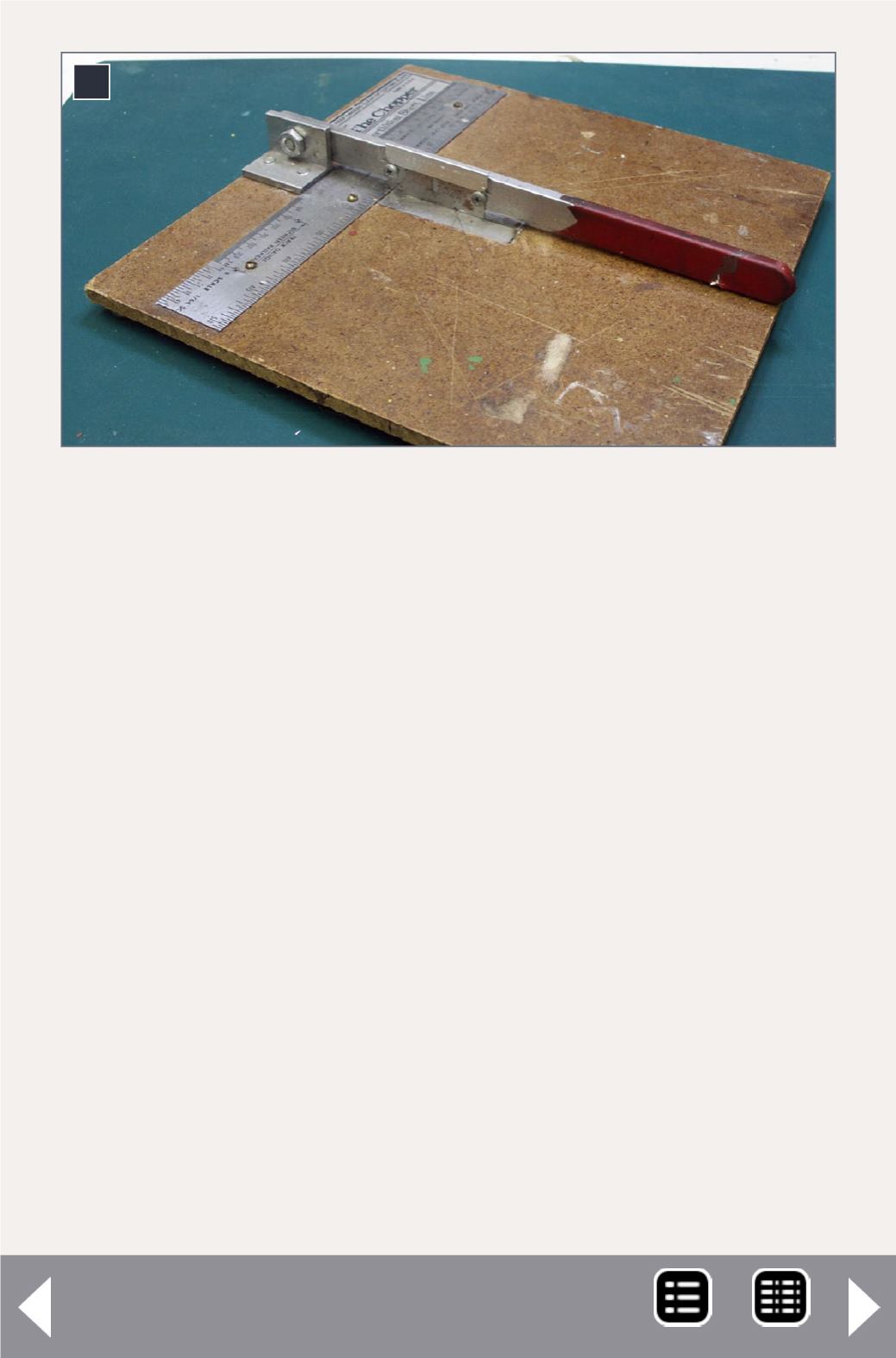

2. Here is my Chopper in the closed position. The slot

created between the lengths of tool steel allows the

blade to pass completely through the material being cut.

everything was correctly aligned, I used five-minute epoxy to

secure the steel pieces to the base, making sure that they were

flush with the top of the base. Since this causes the steel to

protrude below the base, I epoxied four steel nuts to the bot-

tom of the base, so the base would sit level again.

Since the cutting edge of the razor blade is now between the

edges of the tool steel, I no longer have any problem with

the base material wearing out as I use the tool. My modified

Chopper tool has served me very well over the last 30 years,

and shows no sign of deterioration.

Making the jigs

Next I had to determine how to make jigs so I could construct

all my windows and doors in them, and they would turn out

square and true. I wanted to be able to make different sizes

of doors and windows using these jigs in such a way that the