Building the actual track lay-

out causes some adjustments

and creates some opportunities. I solder about foot-long sec-

tions of electrical wire to the bottom of each metal rail joiner

prior to using them to connect track. In some cases, I need to

connect wires to the rails. Practice is needed to minimize dam-

age to the track. Peco does show some connection clips which

might be interesting to try.

The DPDT switch will control the polarity of the tight curved

reversing section of the wye. Some temporary method of fas-

tening this switch (e.g., tape, glue, or a small board) will be used

until a control panel is made at a later time. The electrical wires

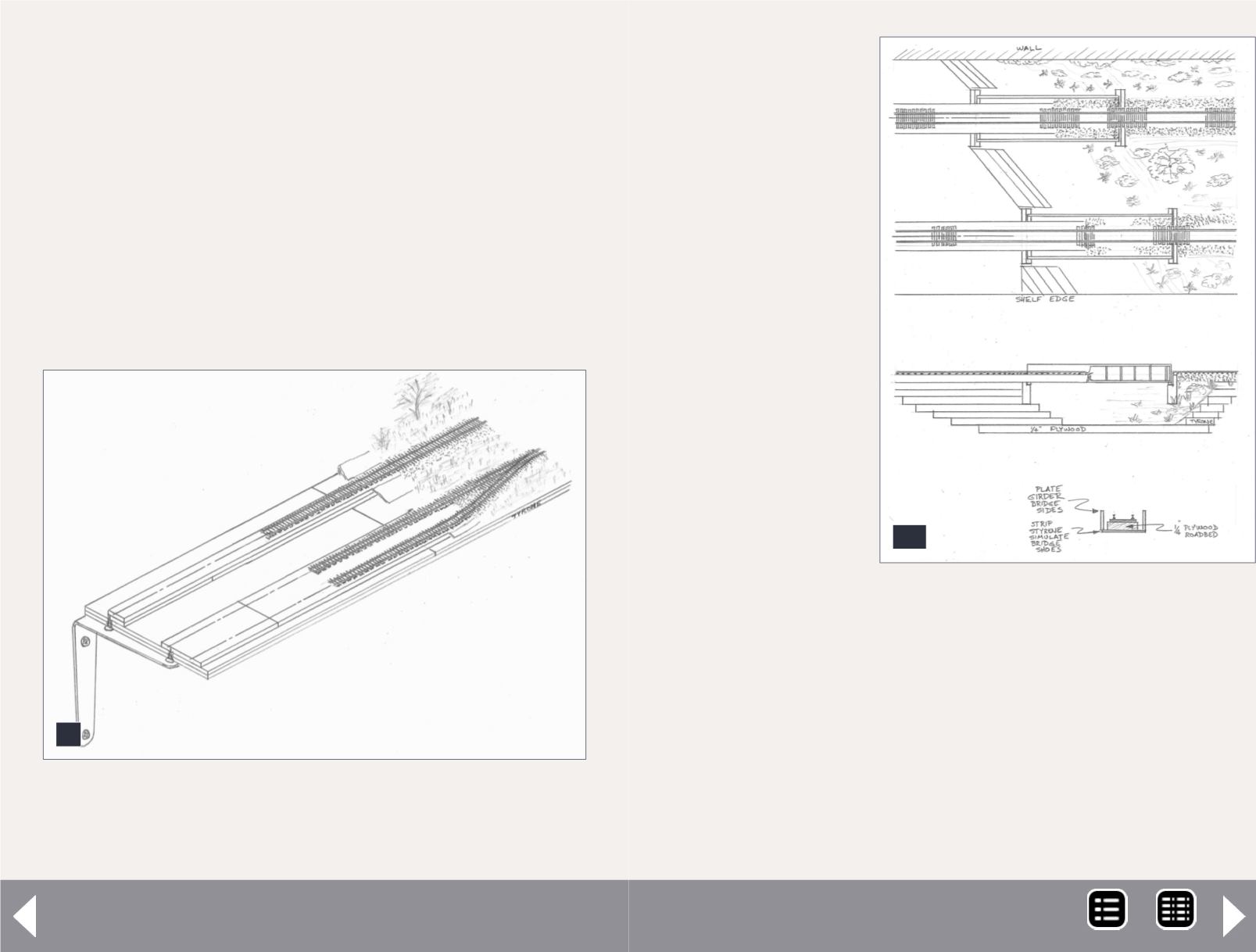

9. This sketch shows my proposed construction of

the shelf layout portion. I plan to use “L” brackets to

support the shelf.

9

$500 layout grand prize - 9

from the rails and rail

joiners are generally

run above the board,

eliminating the prob-

lem of drilling through

the door panel. The

wires are held in place

with quick-tack glue,

and will be eventu-

ally hidden with both

paint and ballast ,and

other scenery.

Layout

construction

I cut some of the ply-

wood into 8”-wide

strips, six of them 4’

long each. Cutting off

the 4’ ends is easier

for me to work with

and to cut with my

hand saw. I also cut

one 4’ strip 2.25”

wide and three at 1”

wide. The first set will

become the shelves

when laminated to double thickness. The last narrower strips

are the roadbed. The wider roadbed is for the double-track

sections, and the narrower is for the single track.

These are then laminated in an overlapping fashion over the

previously laminated shelves. The shelf brackets are attached

through the drywall into each stud, such that the resulting

roadbed surface was level with the door panel top surface.

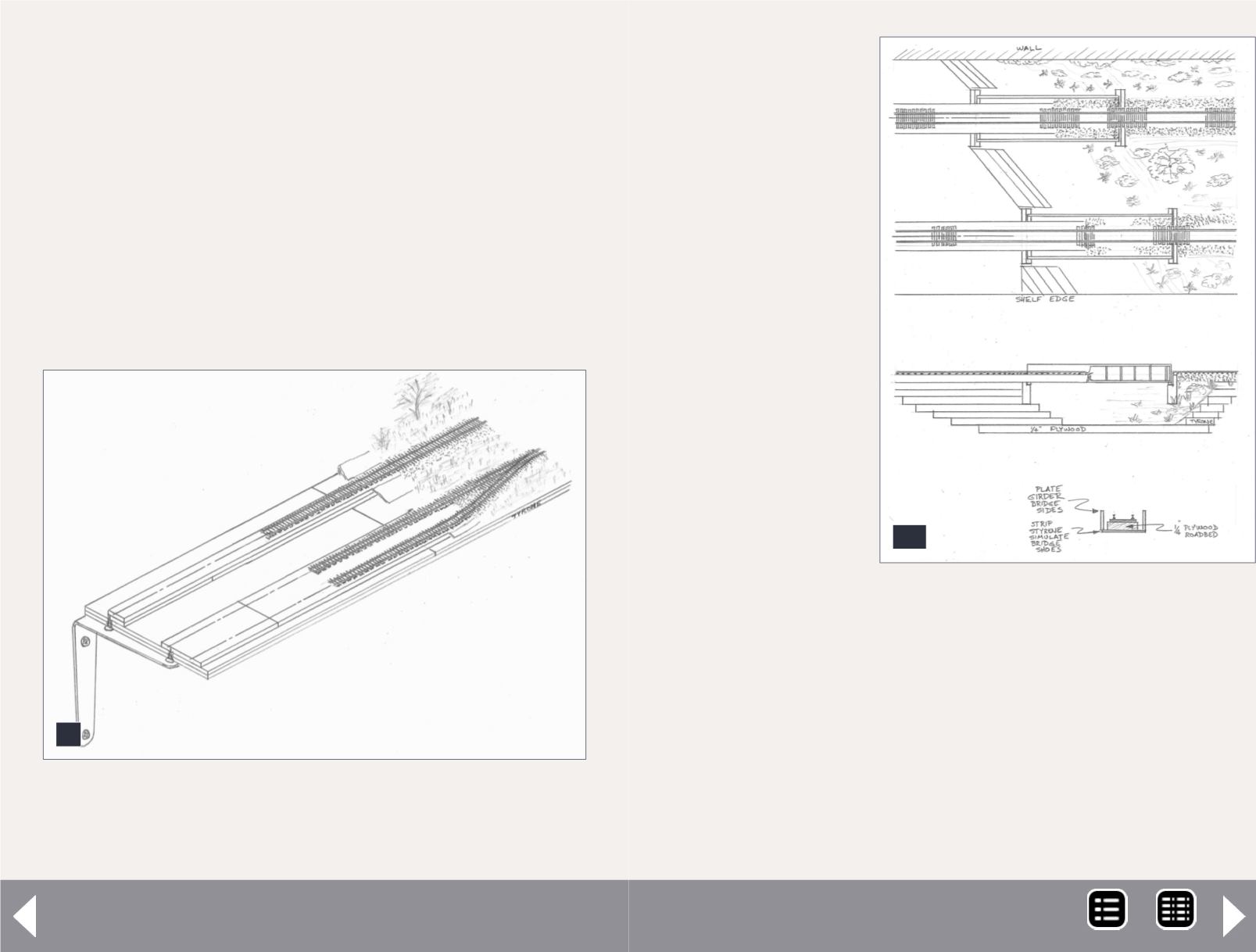

10. This sketch shows

construction details of the

bridge.

10

MRH-May 2014