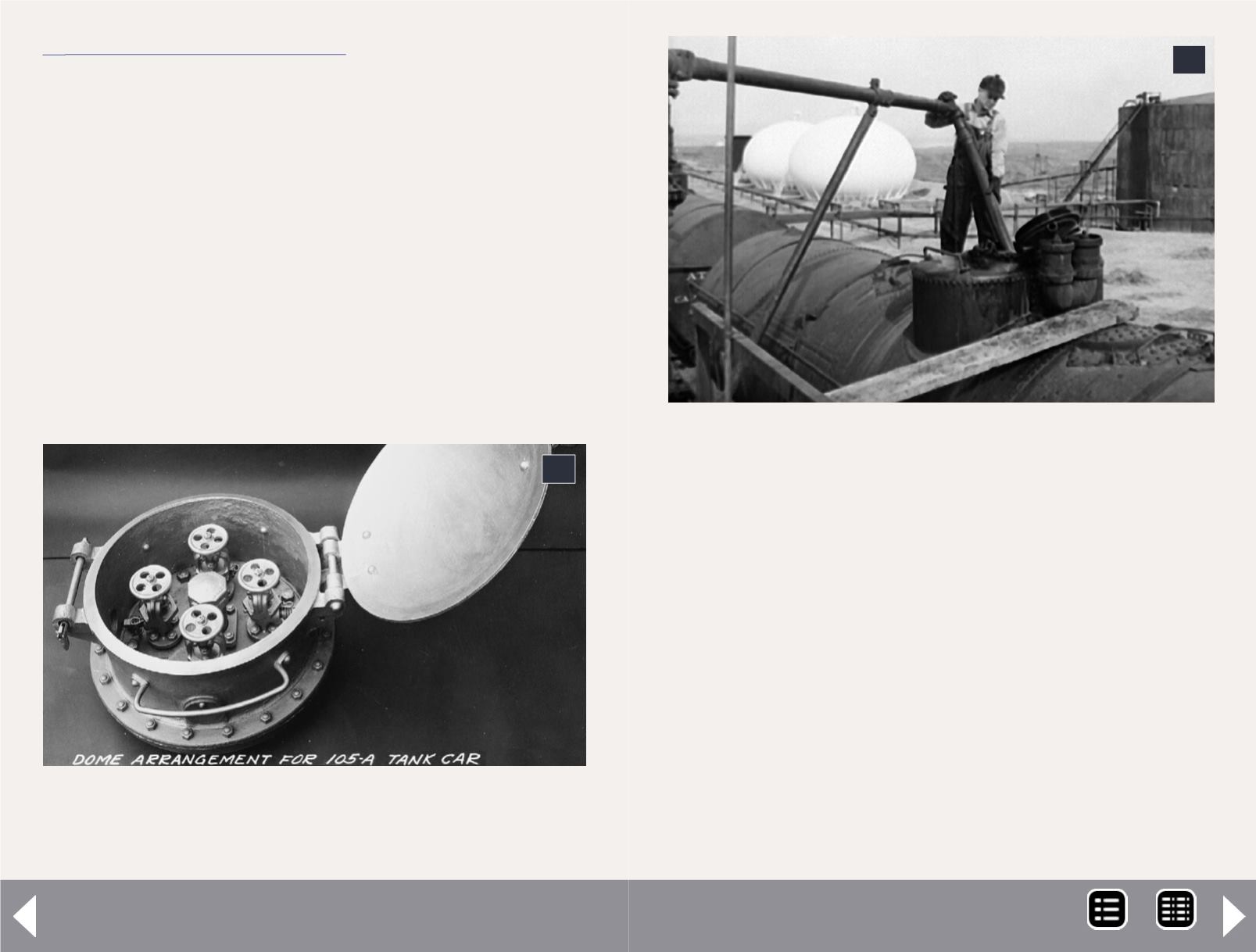

23: The interior of the valve casing on a high-pressure

tank car (ICC 105). – American Car & Foundry photo,

courtesy Ed Kaminski.

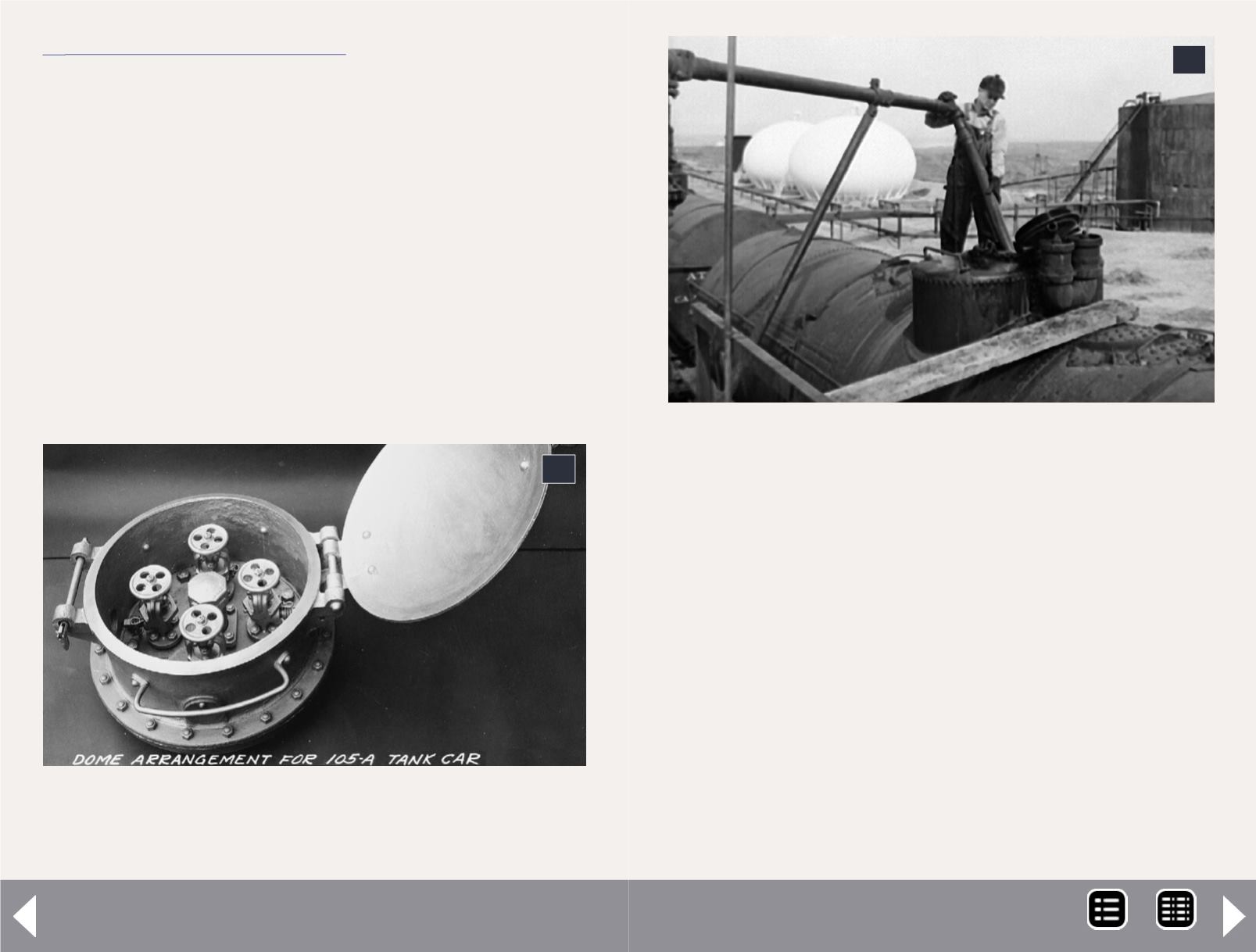

24: Loading oil at the Phillips refinery in Borger, Texas

in November 1942. The boom with rotating pipe joints

is fed from the platform. The workman has crossed to

the tank from the platform at left with a length of lum-

ber. – John Vachon photo, Library of Congress, no.

LC-USW3-011638.

for loading and unloading the cargo, and appropriate valves.

23 shows the interior of such a housing.

A workman would climb the car’s side ladder to the walkway,

or step across from a platform. Either way, he had to work

safely around the high-pressure fittings for the car’s cargo.

It was common to provide some sort of elevated platform,

roughly 10' off the ground, to make it easier to do this work.

24 shows a workman loading a tank car, but you can see that

he has used a plank to reach the tank top from the platform,

and he is simply standing atop the tank. This might be not be

satisfactory if he had to make pipe connections and manipu-

late the valves and fittings of a high-pressure car as part of

the job.

I decided to make a small platform for this purpose. It only

needs four legs, a top, and a ladder or stairway for access. I

first cut the four legs from scale 4" x 4" styrene and braced

them across the ends with scale 1" x 6" styrene, 25. I also

added some brass ladder stock. The piping and the railing are

taken from the McGraw Oil kit. The resulting structure is quite

simple, (26).

The warehouse

For my available space, I designed a building which is 18' x 31' in

size. I decided to model it with Evergreen clapboard siding, their

23

24

Getting Real Column - 14

MRH-Mar 2014