push pieces together, squeezing out a little plastic that is eas-

ily removed later. This makes a super tight and secure joint.

If I need things to set up quickly I switch to Ambroid ProWeld

“plastic welder” which is exactly what it does, quickly.

Once again the walls went into the squaring jig and were

cemented together. Before adding the roof, I made the inte-

rior loading docks and a few interior walls of plain styrene. The

building was painted with Floquil ATSF Mineral Red, and later

grouted with spackle carefully rubbed on, then lightly rubbed

off, so just enough sticks inside the cracks. It is possible to

remove the dry paint if you rub or push too hard. Weathering

washes were added later, as were those little Grandt Line

12

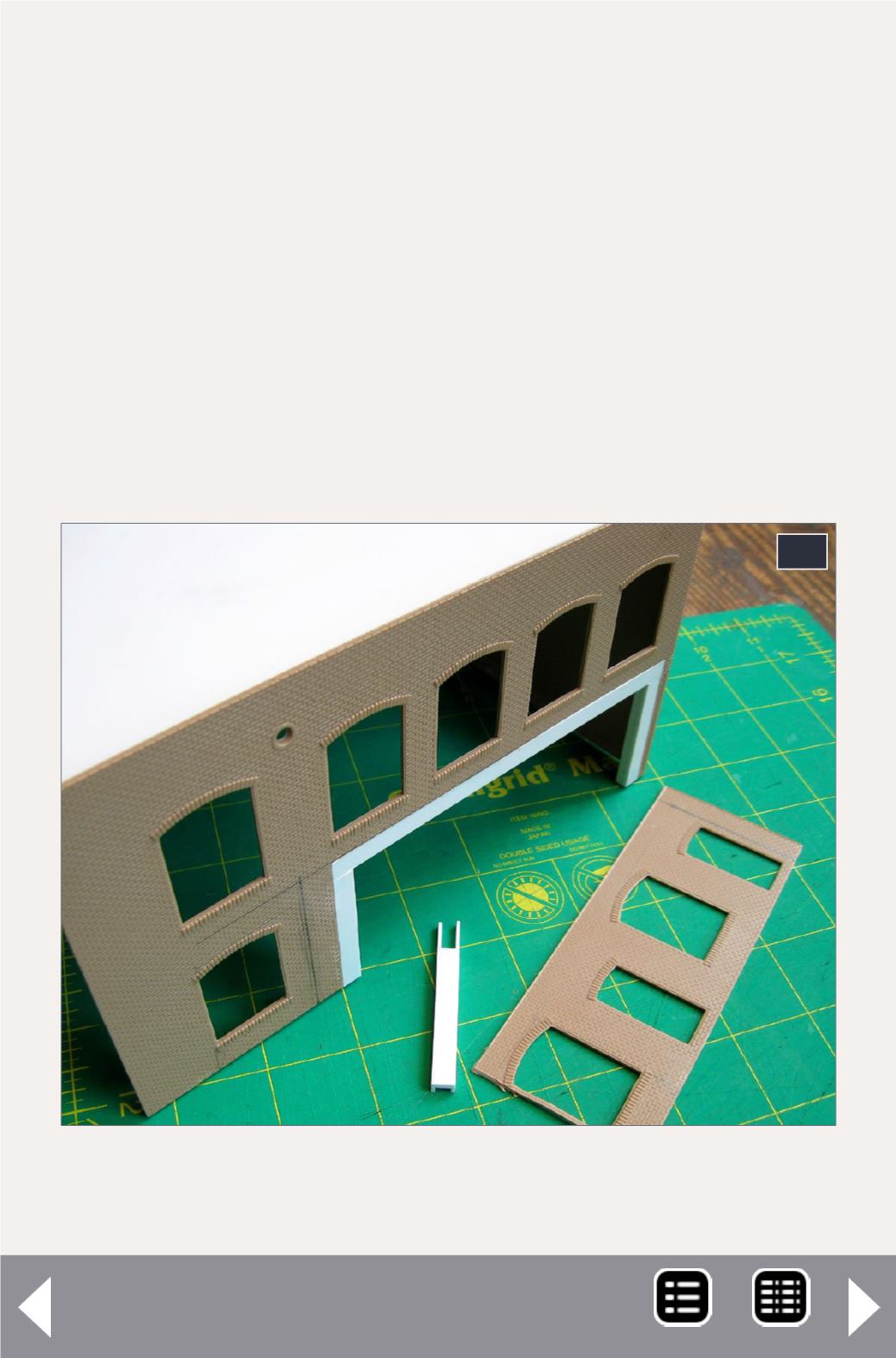

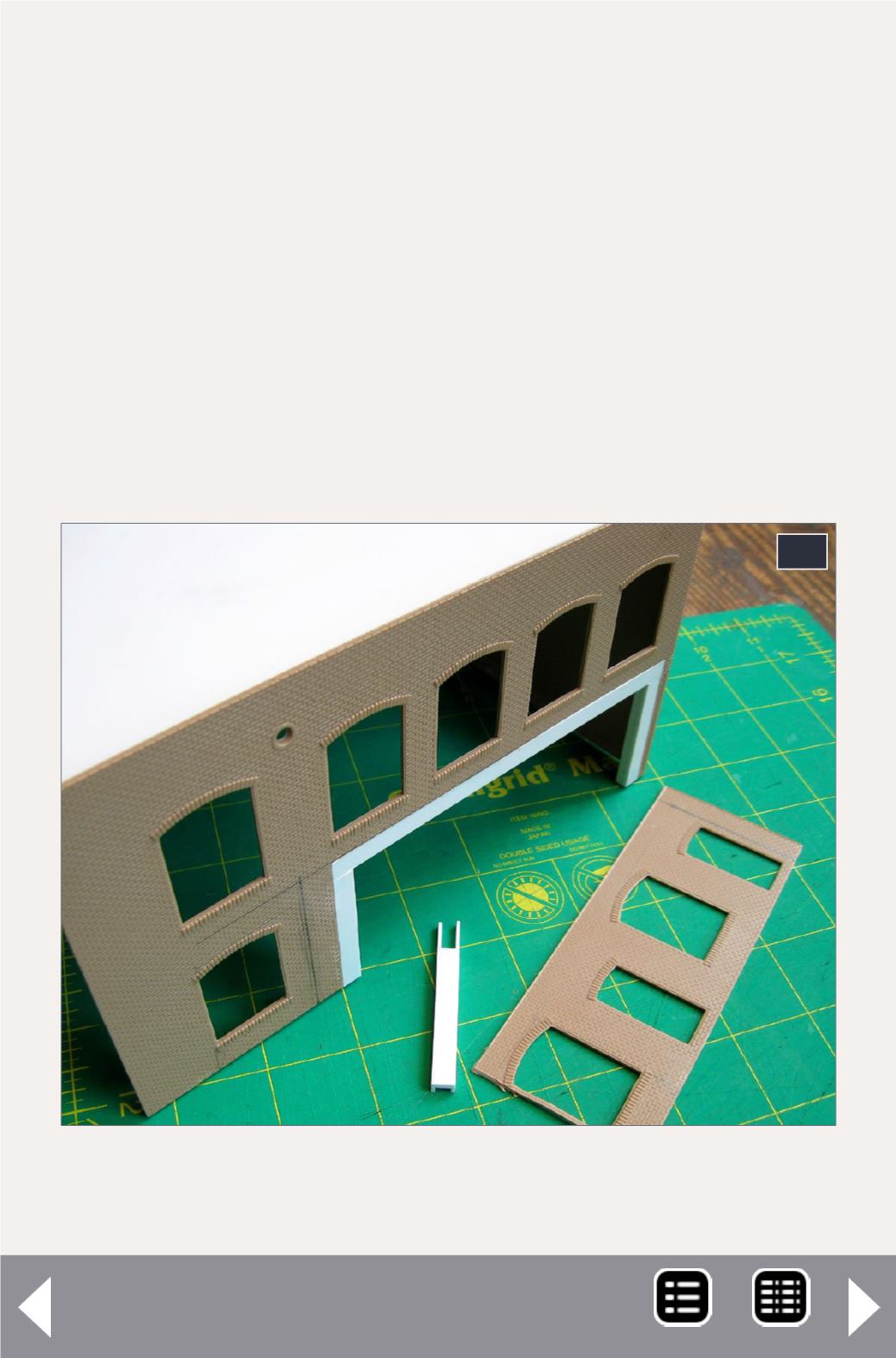

12: The cutout with styrene columns and beam for the

loading docks on Merchant’s Row III.

Structures in tight places - 7

MRH-Feb 2013