The Lite and Narrow Column - 9

to the processing plant; from photos of other larry cars in use,

it wasn’t common practice. Instead, the cars moved coal from

a hopper to the trunnel head (opening) and dumped.

There were two methods of moving the larry cars atop the

beehives. The first used a trolley pole and a power line

erected over the tracks. A wooden roof covered the operator’s

platform. The other method used a small steam locomotive to

move the cars. The tracks were mounted on brick and concrete

columns built at the same time as the beehives. These columns

were 12’10” x 2’6” and placed at 14’ intervals. The rails

centered on concrete pads 2’6” x 2’6”x 1’3”. The center of the

fill hole for the beehive was located 5’3” from the front wall,

while the center of the larry track was an additional 7’3” from

the center of the fill hole. Three cross ties were equally spaced

between the columns.

These measurements are taken from Historical American

engineering Record (HAER)

, drawing for the beehive coke ovens at

Connellsville, PA and there is a disclaimer stating “topography

and operating costs determined the configuration of beehive

coke works. Coke ovens were always built in rows, and a single

row built into the hillside was called a ‘bank’.” This is a factor to

be considered when building your models.

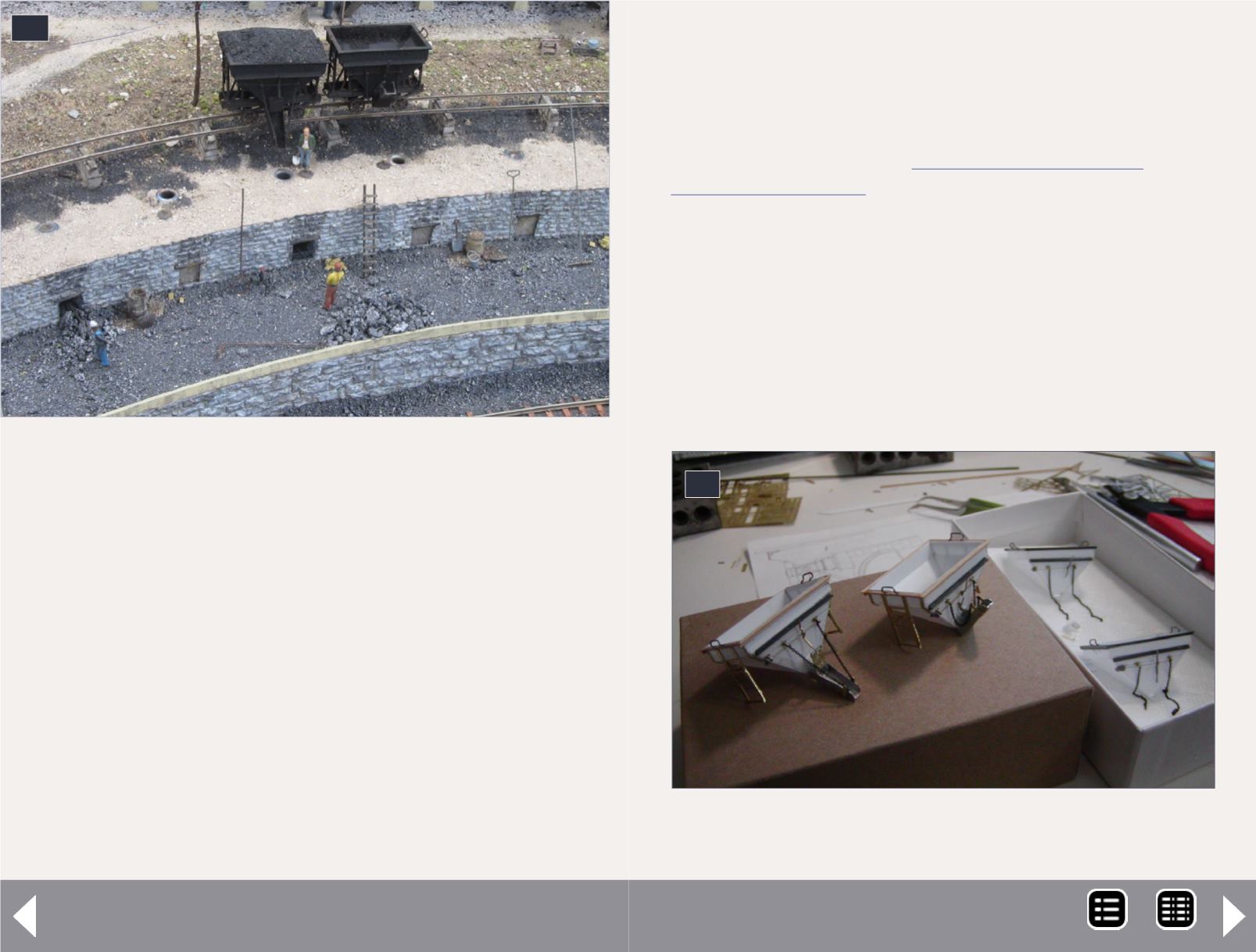

Modeling larry cars

Thomas Maule, a narrow gauge friend of mine, is modeling the

Mann’s Creek Railway and built larry cars for his coke ovens

11

11: The bodies of two small larry cars under construction

by Tom Maule. Tom Maule photo.

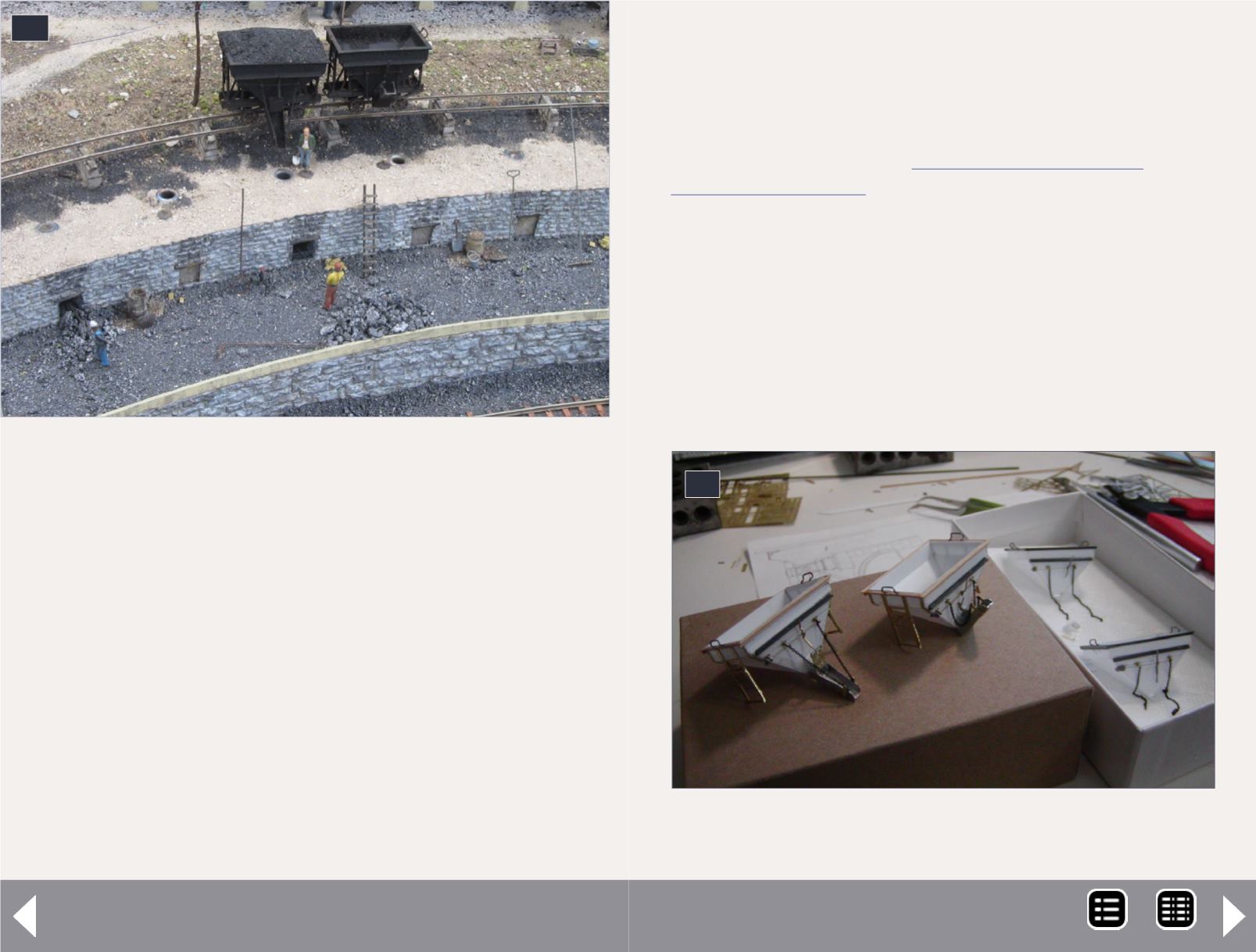

10

10: Larry cars in position for charging the ovens at

Sewell, WV on the Mann’s Creek Railway. Ron Lane

photo.

MRH-Dec 2013