The Lite and Narrow Column - 5

a fuel for use for smelting ores and manufacturing of met-

als, and 1627, for removing the coal smell or smoke for use in

heating houses.

In 1709, Abraham Darby developed a blast furnace using coke

for firing. Because of coke’s superior resistance to crushing,

blast furnaces could become taller and larger. This one devel-

opment made iron less expensive and was one of the factors

leading to the Industrial Revolution.

Charcoal was the primary source of coke; however the rapidly

dwindling forests created the need to find a better source for

coke. Early coke, from coal, was produced by burning coal in

heaps on the ground so that only the outer layer burned, leav-

ing the insides free of the gases and oils; in other words baking

the coal. This wasn’t very efficient.

A similar situation occurred in the United States changing from

wood to coal because of depletion of the forests for fuel in the

salt brining industry. In this instance the development of the

coal mining industry in West Virginia started.

Beginning in the late 1700s beehive ovens were developed to

allow better control over the burning of the coal. They consist-

ed of a chimney constructed of loose bricks, and several open-

ings for the combustion gases to enter. As more experience de-

veloped with these ovens, the yield became better, from about

35% to 65% of usable coke by the mid-1800s.

distinction of building the world’s longest coke battery, with

475 ovens over 1.25 miles. The output from these ovens

reached 22,000 tons per month.

Modeling a coke battery

Flexibility is the key word when modeling a coke battery. I

built my coke battery one way, but there other options. I used

castings by Scale Model Masterpieces, the former Tom Yorke

castings. The prototype for these castings is the ovens of the

Cascade Coal and Coke Company, at Cascade in Preston County,

WV. The ovens were built in 1903.

The castings come with the doors bricked closed and have to be

opened to indicate an oven that is being charged or just pulled.

They are cast in LabStone so the material is easy to remove using

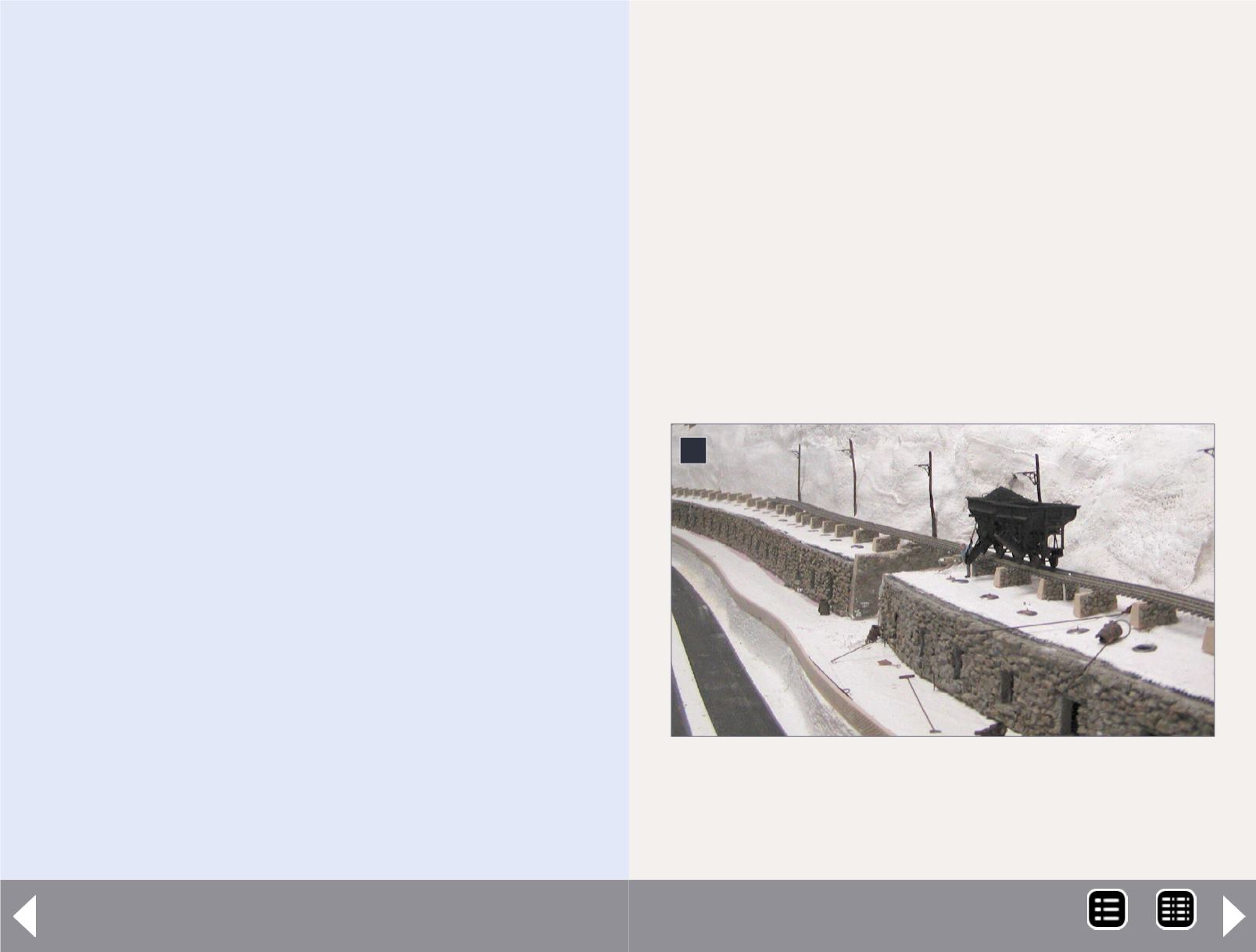

4: Tom Maule’s coke ovens under construction on his

Mann’s Creek Railway give an excellent view of the trol-

ley system used at the Sewell beehives.

Tom Maule photo.

4

MRH-Dec 2013