nonperfed and unclad prototype board. The prototype board

was a little stiffer than other materials, withstood heat (good

when cutting the excess thread from the Tortoise mounting

screws flush), and held the screw thread a bit better than sty-

rene or wood. Installing the Tortoise "top down" had a very

nice low profile, with very little of it exposed to damage while

module transported.

It is imperative that you know the exact location of each

turnout and throwbar actuator hole. Take your time and lay

out your track exactly where it is to be located, and make all

adjustments to angles and track centers ahead of time. It is

MUCH more difficult to adjust this once the foamboard is cut

and switch machine is installed.

Maintenance is

a consideration.

Simply cut the

area around the

Tortoise a little bit

larger than neces-

sary to give room

for a screwdriver

to reach the ful-

crum and mount-

ing screws. If the

Tortoise needs

to be replaced,

unscrew the four

2-56 mounting

screws and the

Tortoise drops

from the board.

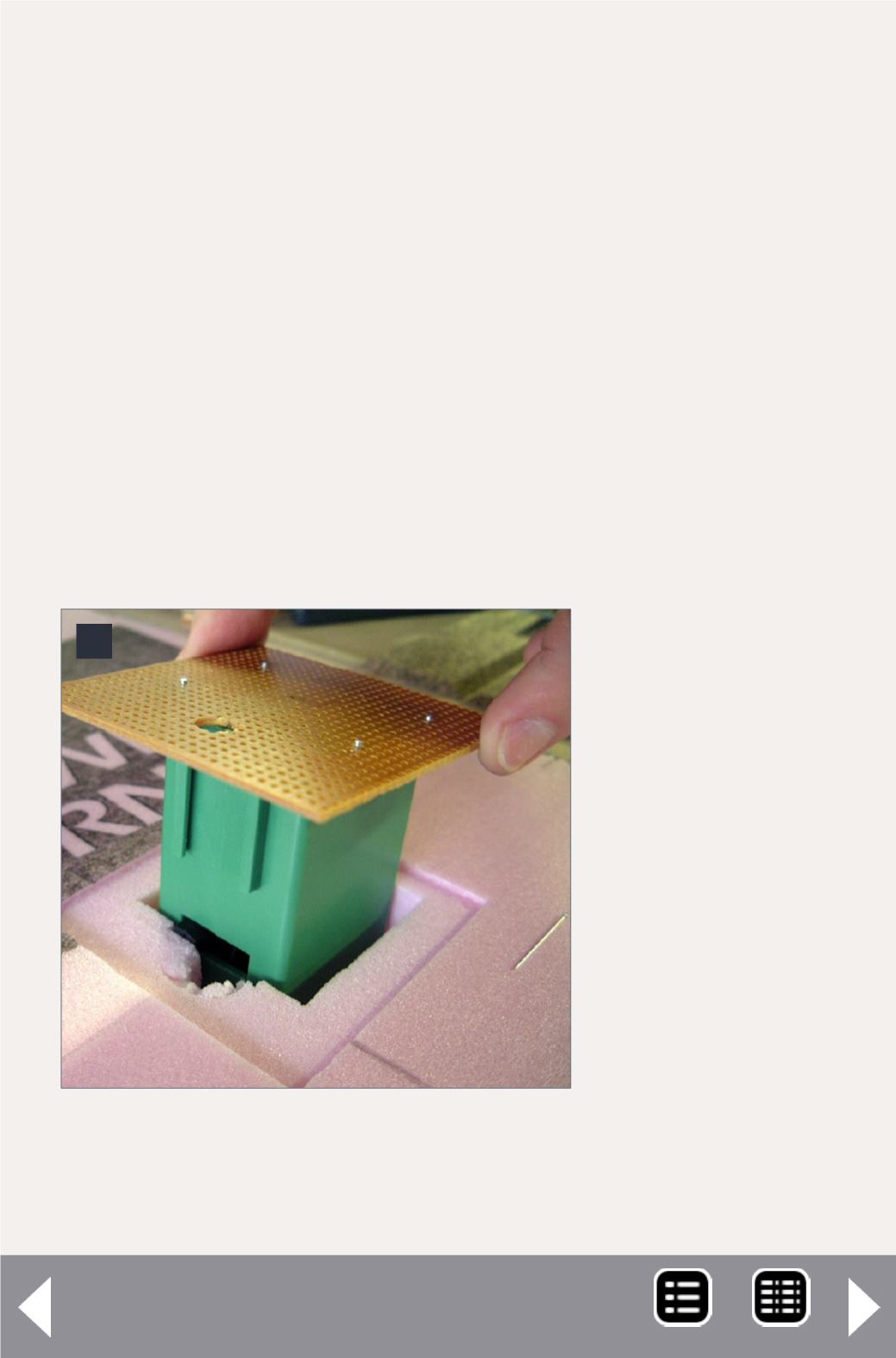

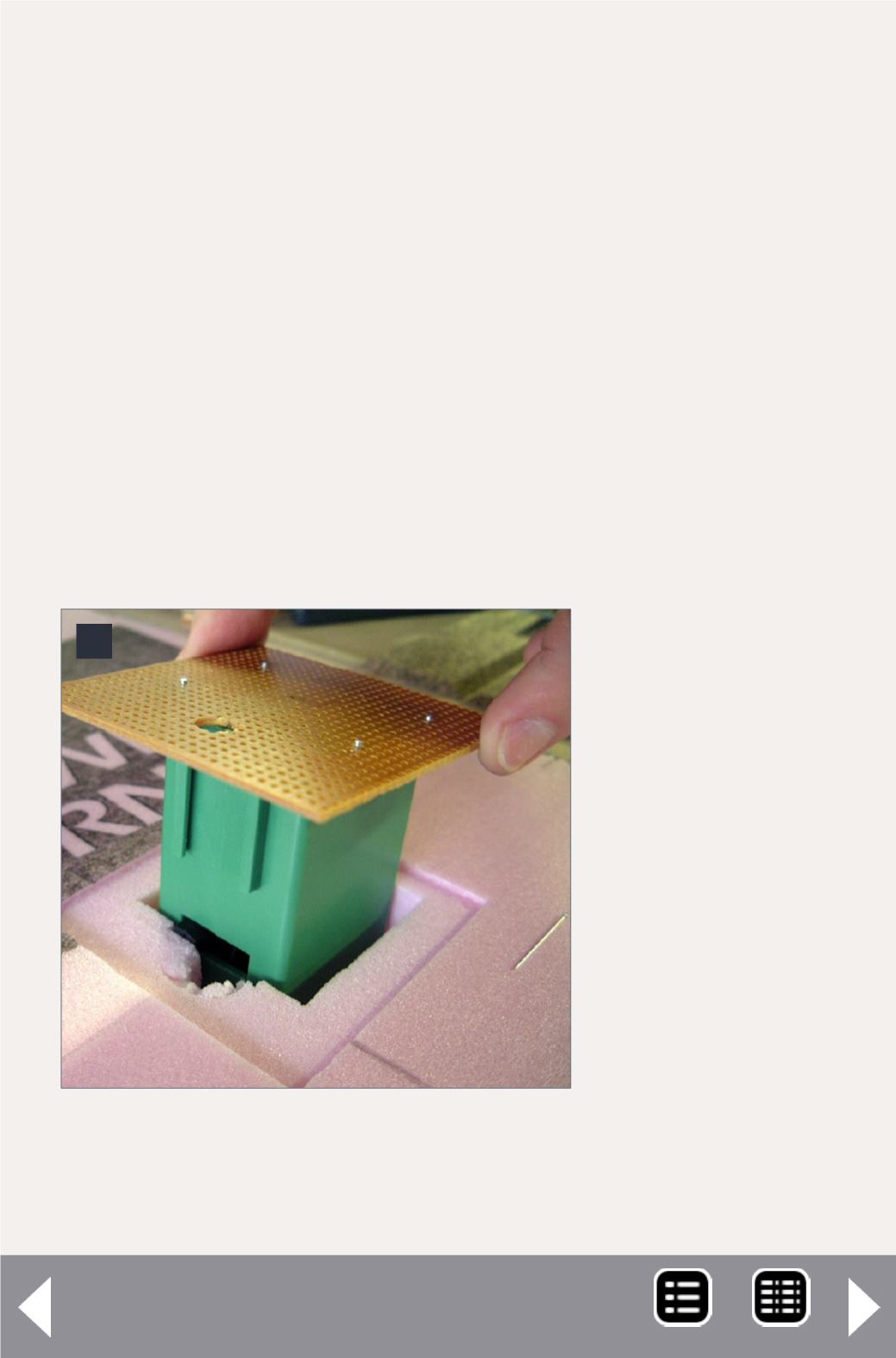

2: A Tortoise switch machine is

attached to a piece of perfboard with

2-56 screws and dropped into place.

2

Switch machines on foam - 2

MRH-Feb 2013