Shoofly free-moN module - 7

7

8

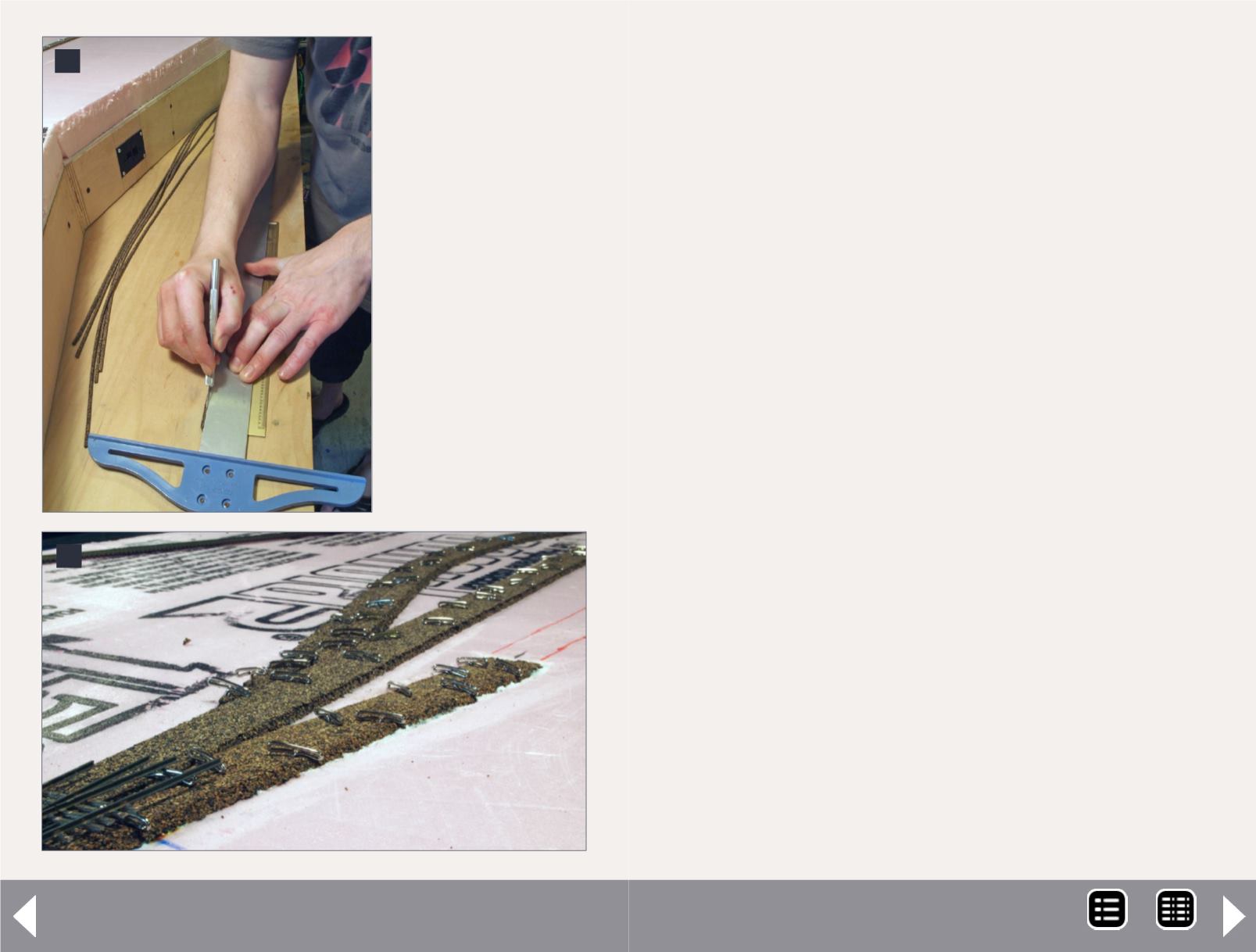

7-8: Trimming

about 1/8” off of

the center of the

cork roadbed strips

gives the track a

more branchline

appearance. T-pins

hold the cork in

place while the

caulk cures. The

transition from

roadbed down to

ground was made

by sanding down

the pink foam into

a sloping channel.

through holes in both cross-support and leg-plate, but secur-

ing the bolts to the cross-support with Gorilla Glue and cut-

ting the channel in the leg plate allows for a much quicker

“slip-on” system, the ease of which proves invaluable during

setup and take down (5).

As the two module sections are clamped securely before

legs are attached, only two sets of legs are necessary for the

entire module.

At first, because I was building the basics of this module in

a month to participate in a show, I used ¼” bolts secured by

t-nuts to level the legs. Adjusting those small bolt-heads under

the 2”x2” legs, over and over again, is hard on the fingers, so

after nine months of use I replaced the bolts with Rockler leg

levelers. The Rockler leg levelers take up 4” more space length-

wise, and a true 2”x2” width-wise, but they are heavy-duty,

easy to adjust, (especially when the weight of the whole mod-

ule is on them) and make set-up 20 kabillion times easier. (6)

Track & Turnout Control

The module required only a couple lengths of Atlas code 55

flex track and cork roadbed. As N scale cork roadbed is still very

wide, I like to trim about 1/8” off from the center side on each

piece (7).

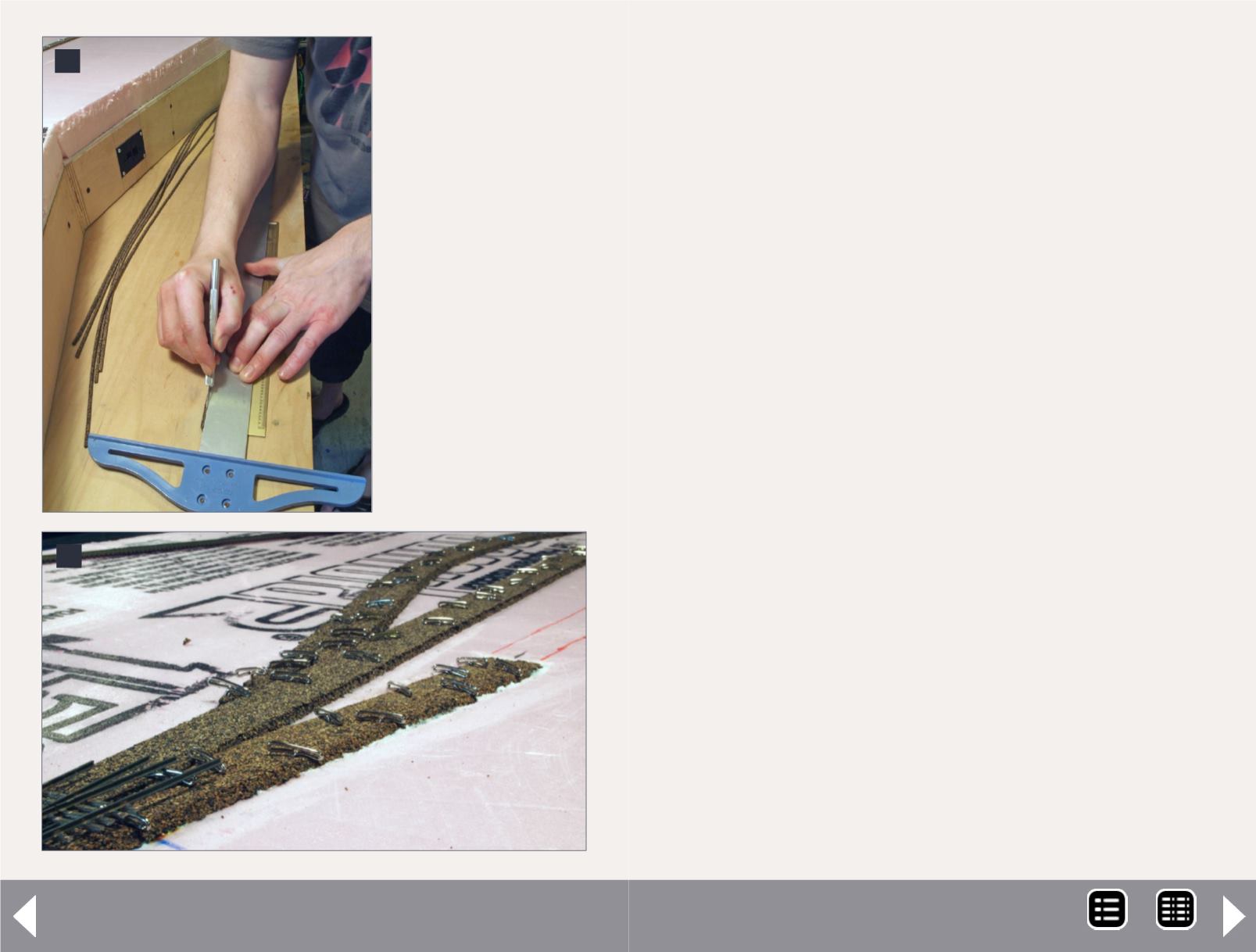

I used clear silicone caulk to secure both the cork to the pink

foam, and the flex track to the cork. T-pins keep everything

in place while the caulk cures. (8) The trick for laying track on

Free-moN modules comes at the module and section ends.

“I used clear silicone caulk to secure both the

cork to the pink foam, and the flex track to

the cork. ”

MRH-Nov 2013