Build a laser kit prt 1 - 7

STEP 4: Building the walls

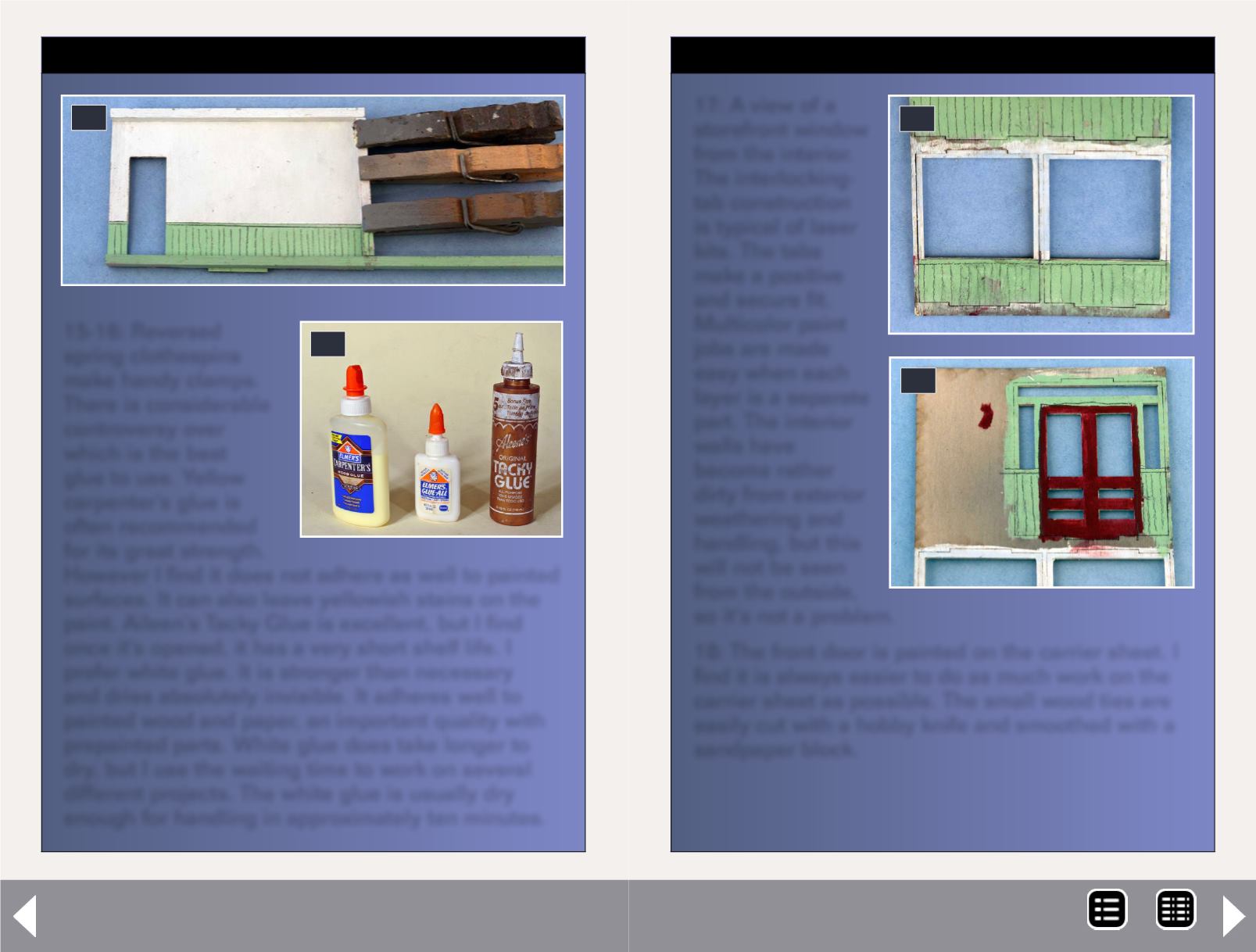

15-16: Reversed

spring clothespins

make handy clamps.

There is considerable

controversy over

which is the best

glue to use. Yellow

carpenter’s glue is

often recommended

for its great strength.

However I find it does not adhere as well to painted

surfaces. It can also leave yellowish stains on the

paint. Aileen’s Tacky Glue is excellent, but I find

once it's opened, it has a very short shelf life. I

prefer white glue. It is stronger than necessary

and dries absolutely invisible. It adheres well to

painted wood and paper, an important quality with

prepainted parts. White glue does take longer to

dry, but I use the waiting time to work on several

different projects. The white glue is usually dry

enough for handling in approximately ten minutes.

15

16

STEP 4: Building the walls

Continued ...

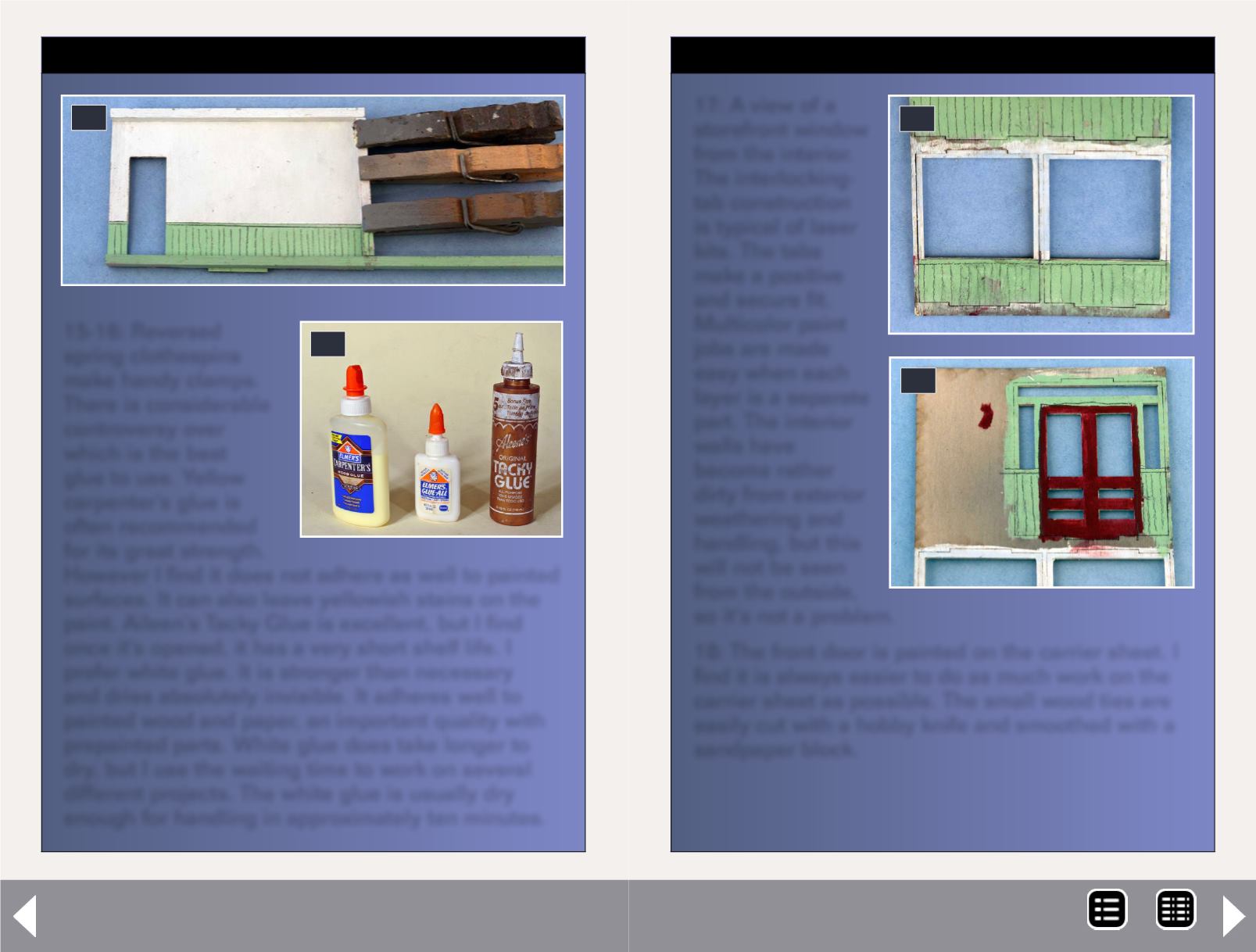

17: A view of a

storefront window

from the interior.

The interlocking-

tab construction

is typical of laser

kits. The tabs

make a positive

and secure fit.

Multicolor paint

jobs are made

easy when each

layer is a separate

part. The interior

walls have

become rather

dirty from exterior

weathering and

handling, but this

will not be seen

from the outside,

so it's not a problem.

18: The front door is painted on the carrier sheet. I

find it is always easier to do as much work on the

carrier sheet as possible. The small wood ties are

easily cut with a hobby knife and smoothed with a

sandpaper block.

17

18

MRH-Sep 2013