Aisle Swing Gate - 4

make sure the trackwork fit with the fixed roadbed on either

side, I laid a continuous piece of plywood sub-roadbed

across the entire aisle gate area, and secured it to the fixed

benchwork on both sides. I placed supports under it and

secured it in place with glue and screws. I only cut the mov-

ing parts of the sub-roadbed free after ensuring that all sup-

ports were in place.

To eliminate the possibility of interference of wood on wood, or

rail on rail, I used a cam action when cutting the sub-roadbed.

Instead of having an arc centered on the hinge pins, I placed a

tripod 3” out in the aisle and marked a circle at the open end

with the circle center offset by that 3”. I used a jigsaw to cut the

plywood sub-roadbed in a straight line at the hinged end, and on

the cam action curved line on the open end. Once these cuts are

made, the gate can be opened, closed, and checked that nothing

binds or interferes with smooth operation.

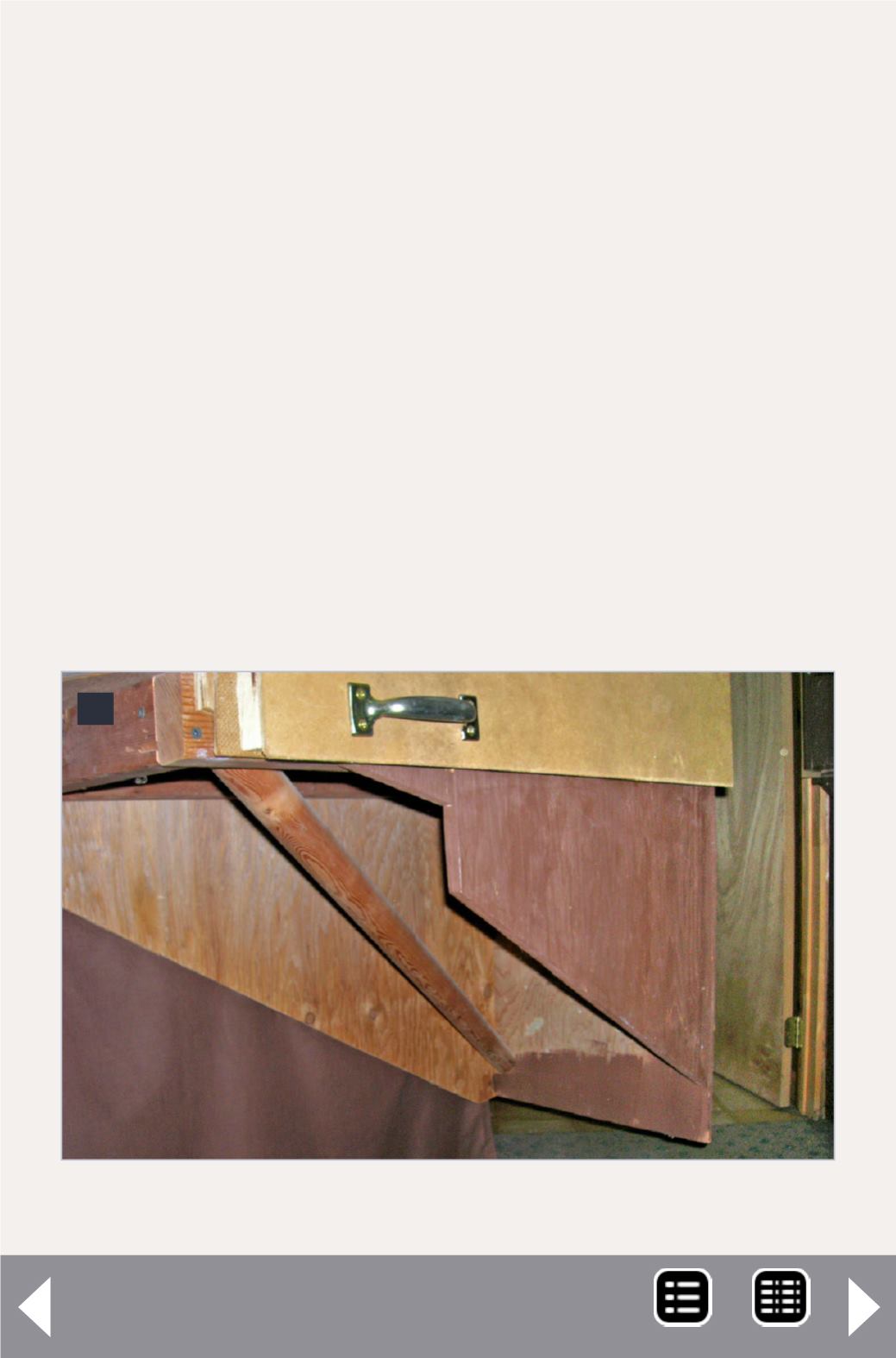

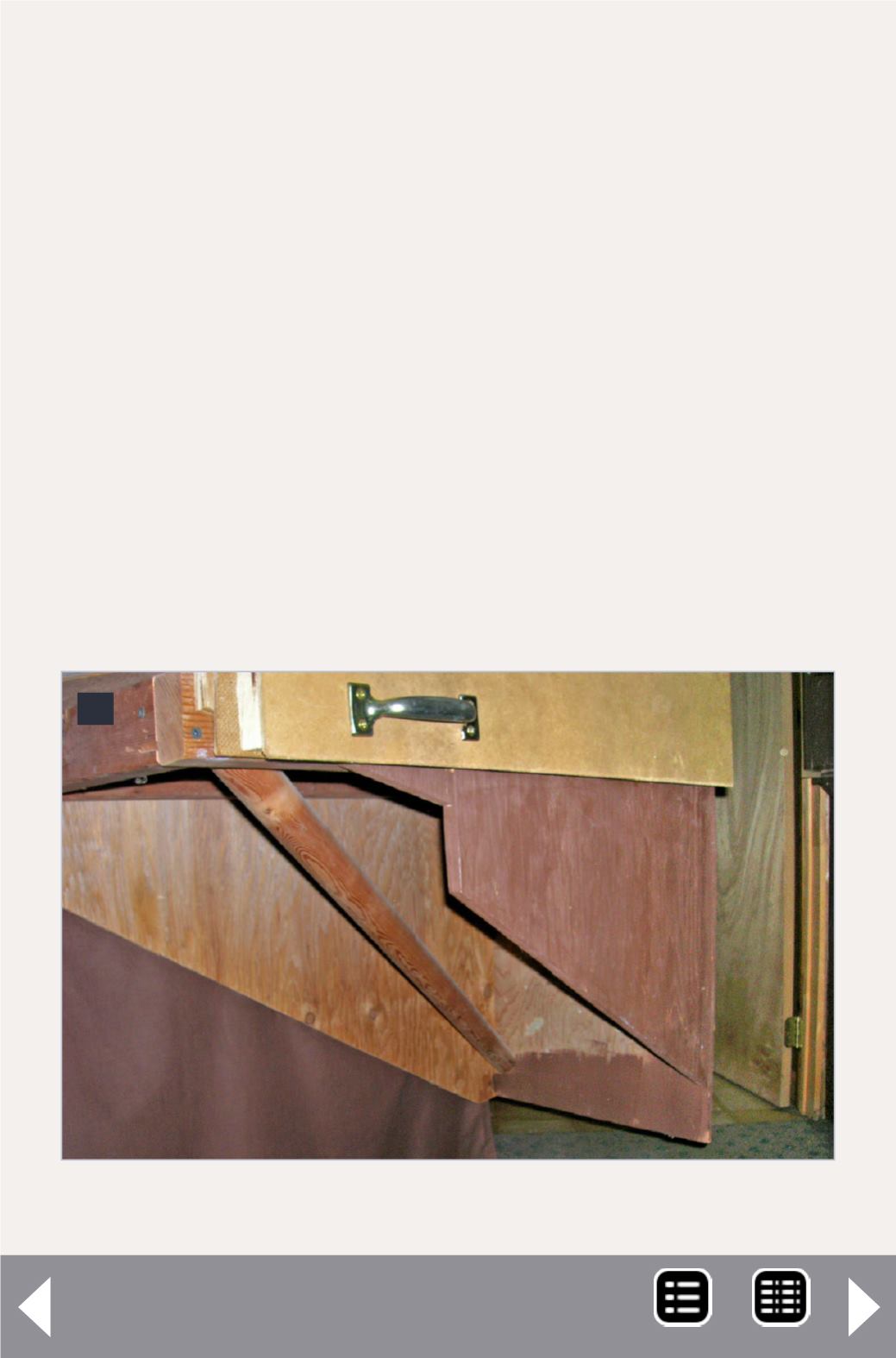

5. Underside of gate.

5

MRH-Feb 2013