STEP 2: Pumping iron – bending styrene

Continued ...

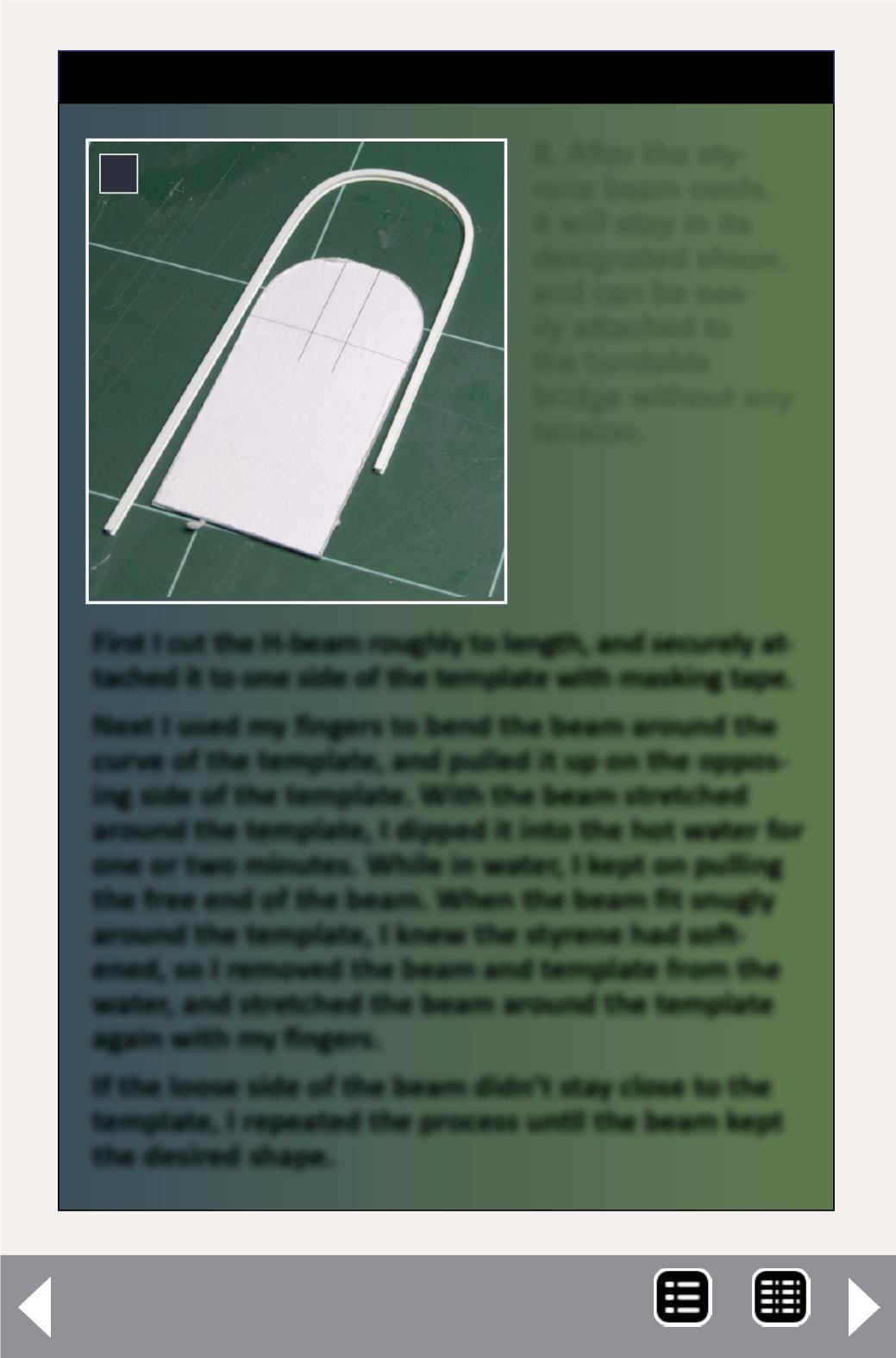

8. After the sty-

rene beam cools,

it will stay in its

designated shape,

and can be eas-

ily attached to

the turntable

bridge without any

tension.

8

First I cut the H-beam roughly to length, and securely at-

tached it to one side of the template with masking tape.

Next I used my fingers to bend the beam around the

curve of the template, and pulled it up on the oppos-

ing side of the template. With the beam stretched

around the template, I dipped it into the hot water for

one or two minutes. While in water, I kept on pulling

the free end of the beam. When the beam fit snugly

around the template, I knew the styrene had soft-

ened, so I removed the beam and template from the

water, and stretched the beam around the template

again with my fingers.

If the loose side of the beam didn’t stay close to the

template, I repeated the process until the beam kept

the desired shape

.