A thin sheet of styrene gave it some depth and I drilled a hole

in the middle for the filler opening. The result looks convincing

enough to me.

Headlights

Next were the headlights. I used a chisel blade in my X-acto knife

to cut the old light castings off. The holes in the shell were now

in the wrong place for the new casting, so they need filling up.

TIP: Here’s a quick and easy technique to do this: Take a suitable

piece of plastic sprue, found in many plastic kits, and gently heat

this up (a lighter or candle works great) until it goes soft. Then

gently pull both ends so it stretches and starts to taper. Remove

the heat and let it harden. Cut the sprue at its thinnest part and

insert it in the hole. Use CA to fix it in place, and then cut off the

sprue flush with the shell using the same chisel knife. You’ll get

a smooth exactly fitting

patch without the need

for any plastic filler.

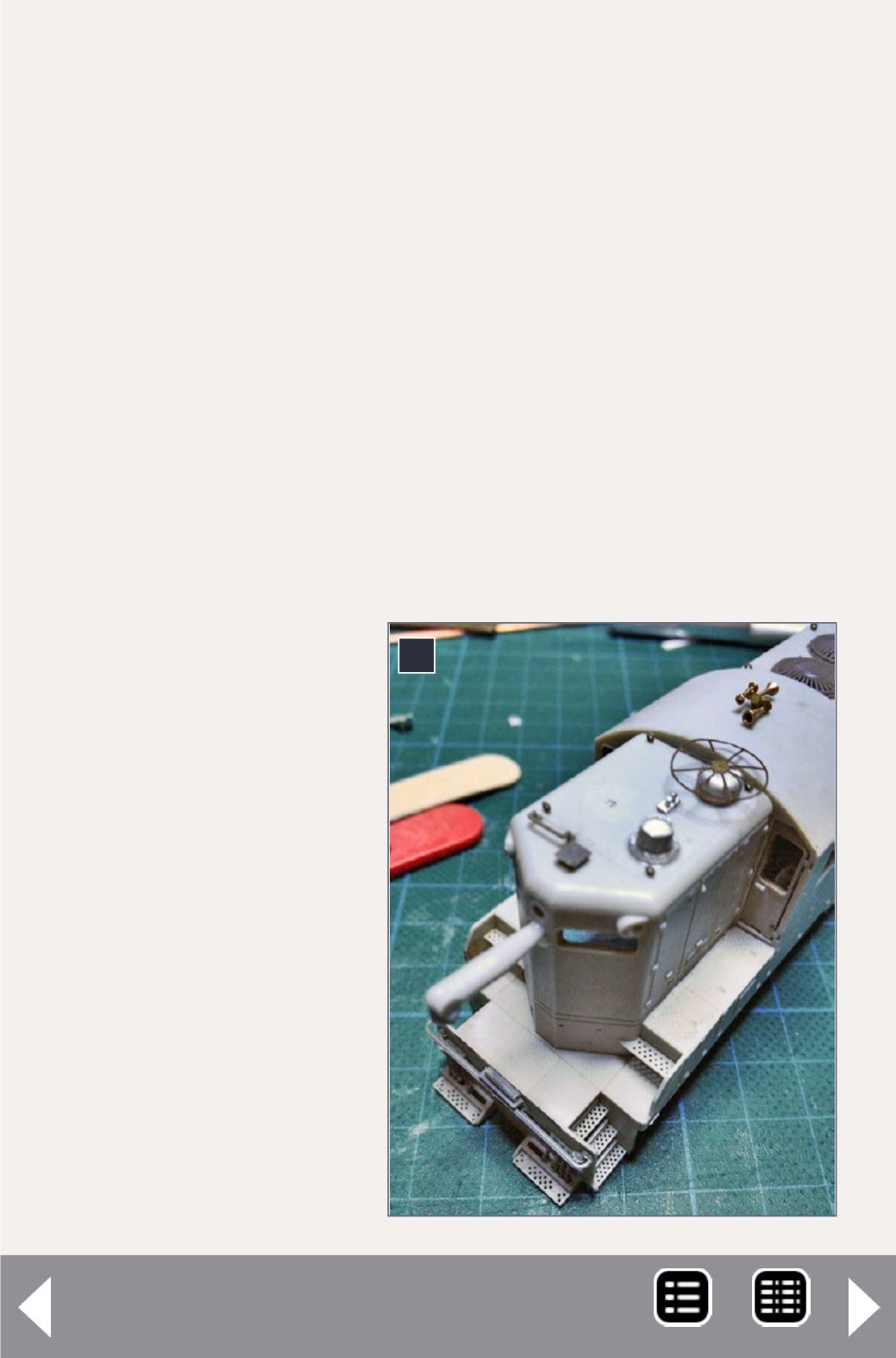

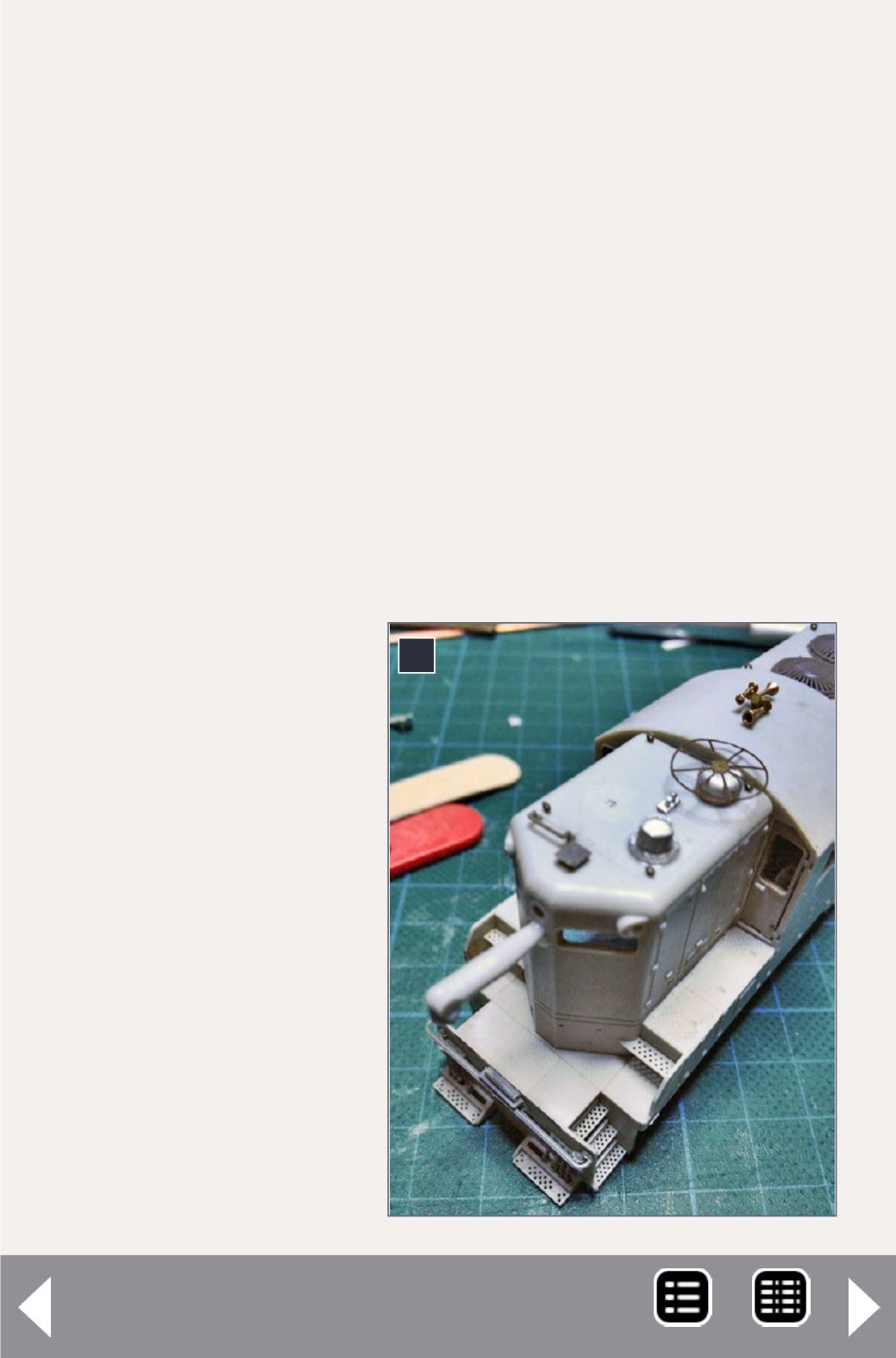

4

4. Headlights cut

off, and holes being

plugged with a bit

of sprue. Steam

generator details

in place. I decided

against the use of

the wagon wheel

antenna in the end,

as it would date the

model too early for

my use.