DCC Impulses Column - 6

This is one place where the PowerCab’s shifting from DCC track to

programming track and back is invaluable. No switches to throw

or think about. Let’s show how this works with a real-life example.

Real-life example

When I install a decoder (or do significant rework on an installed

decoder) my first place to go is the programming track. Why?

Because the current available is limited to a few thousandths of an

amp, as opposed to the many amps or many tens of amps available

on the DCC track. If I can write to and read from a decoder on the

current limited programming track, there is a 90+% chance that I’ve

wired the motor and track portion of the decoder correctly. If I’ve

wired it wrong, I probably won’t have damaged the decoder due to

the current-limited on the programming track.

So here’s how I finish an installation. My goal is to put the loco on

a current limited track and test it before I take it to the high power

DCC track.

I set the PowerCab into programming track mode (press PGM

and then 4), which will start it reading the manufacturer’s ID. I

don’t worry about what number comes up, as it will most likely

be wrong. Why? Because I can’t put the loco on the track until

the PowerCab starts to read the manufacture’s ID. Since the de-

coder gets connected somewhere in the middle of the read pro-

cess, it won’t necessarily return the correct value.

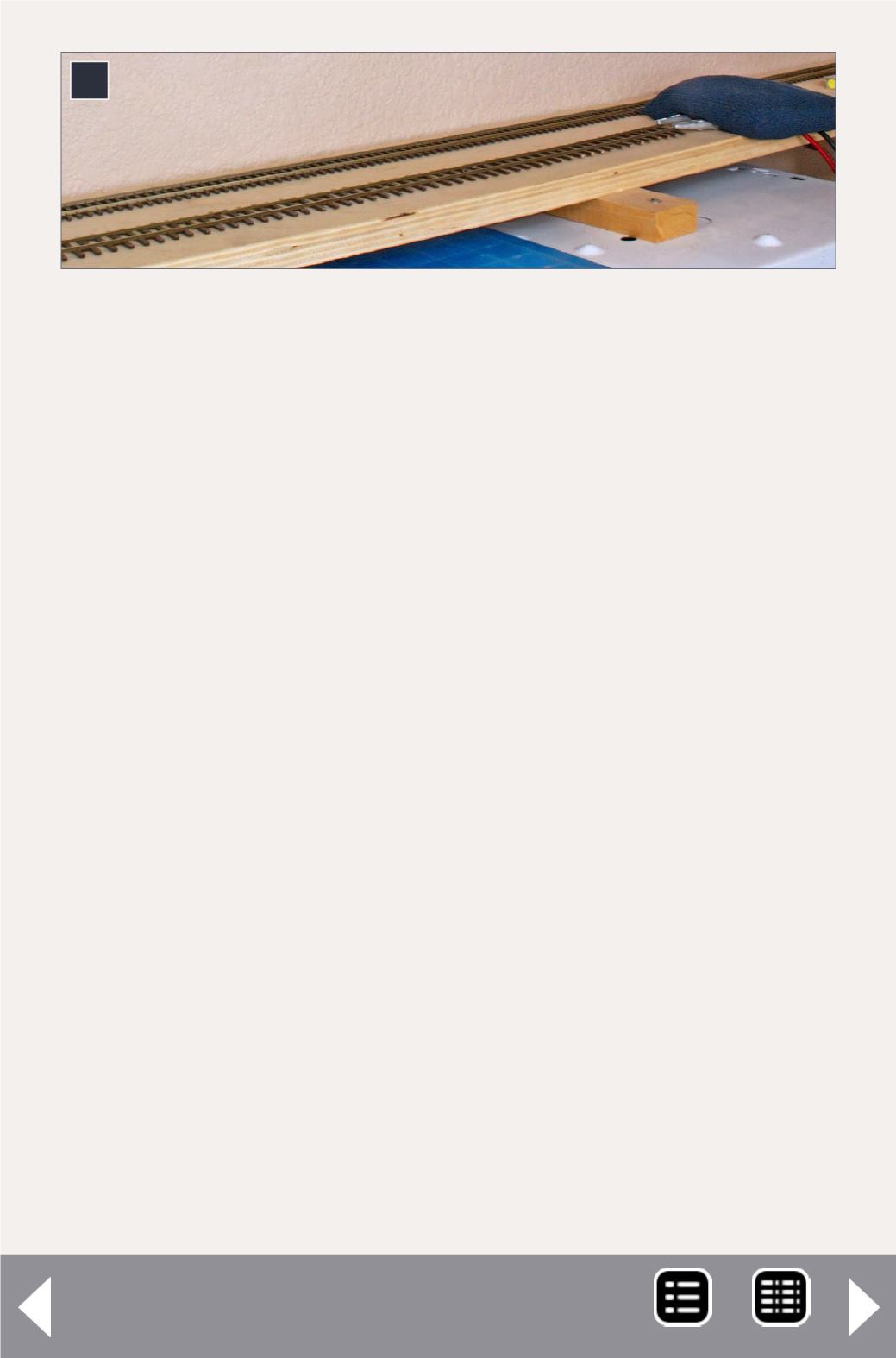

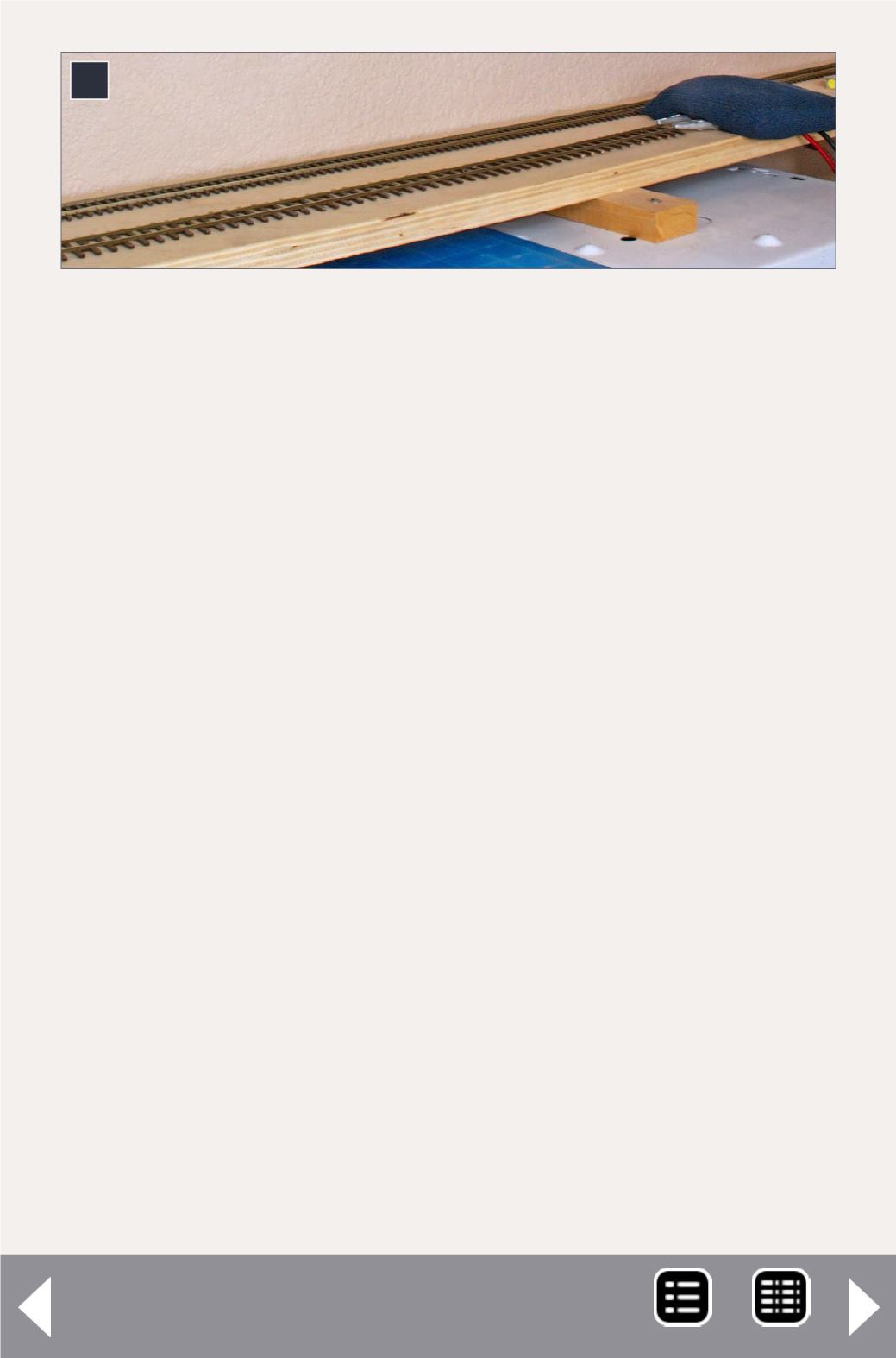

6. My shelf test/programming track.

6

MRH-May 2014