the nibbler head [3]. Be sure to stay clear of the pencil lines as

you enlarge the hole.

Once the hole is large enough to insert the head of the nibbler

[4], you can start cutting out the opening [5]. I usually nibble

my way to one of the sides, cutting right up to the pencil line.

This is easy because the cutting face of the nibbler is straight.

The sides of the nibbler cutter are also square to each other,

making it easy to turn the nibbler 90° and cut right up to a cor-

ner. The nibbler won't make very narrow cuts very easily, so it

is better to nibble to within 3/32″ of a line, and then cut right

to the line with the nibbler for the last cut.

If you are careful, very little cleanup will be needed to have the

window casting fit into the hole [6]. I tend to cut just slightly

4

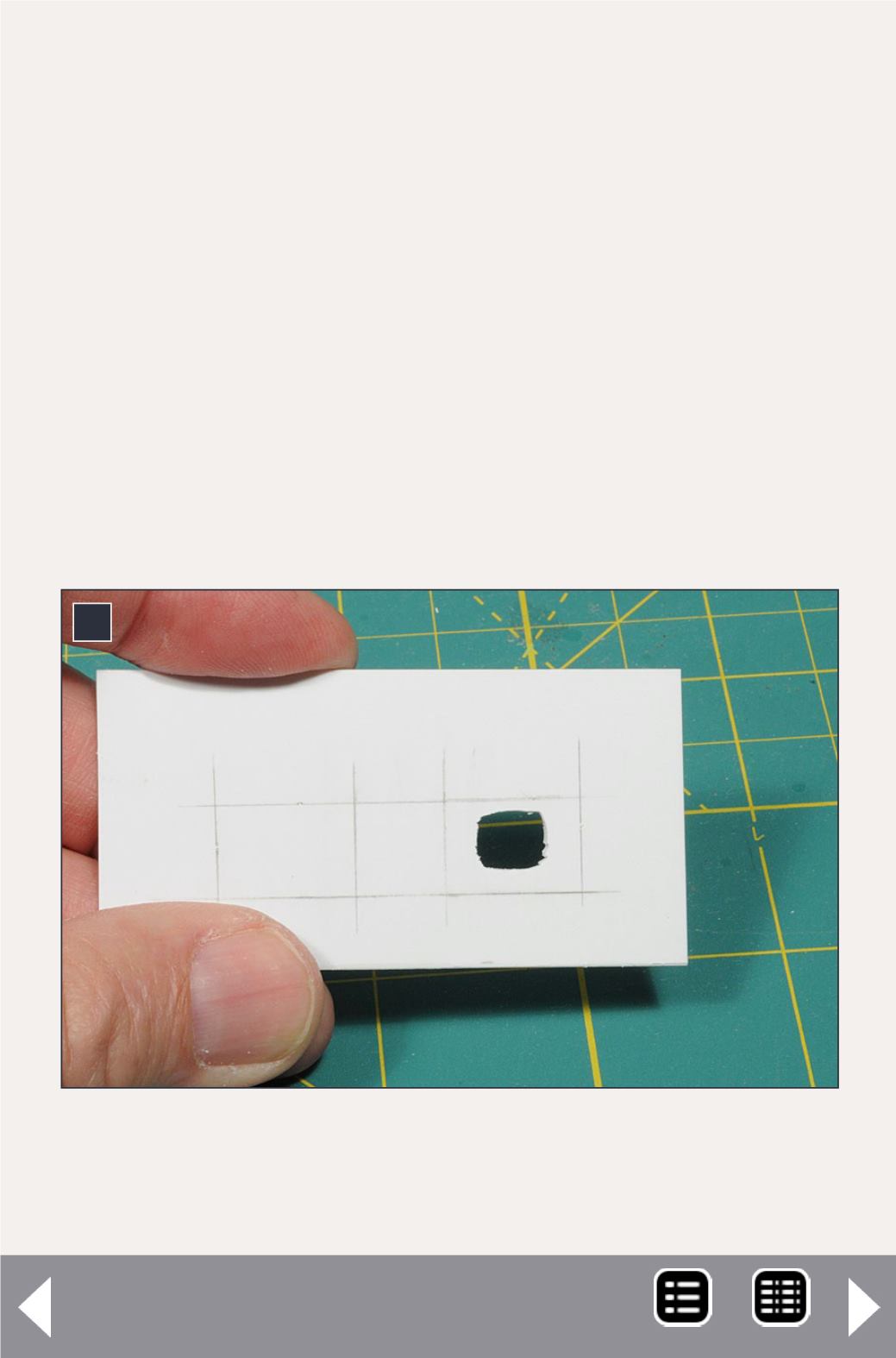

4. Here is the hole after carving. Since the nibbler head is a

rectangle, squaring up the hole will let the nibbler head fit

with less carving.

The Tool Shed - 3

MRH-May 2014