Theheadlight on the locomotiveand theback-up light on the

tender are the same size, somaking twowas as easyasmak-

ingone. I think they turnedoutwell for afirst-timeattempt to

make something like this.

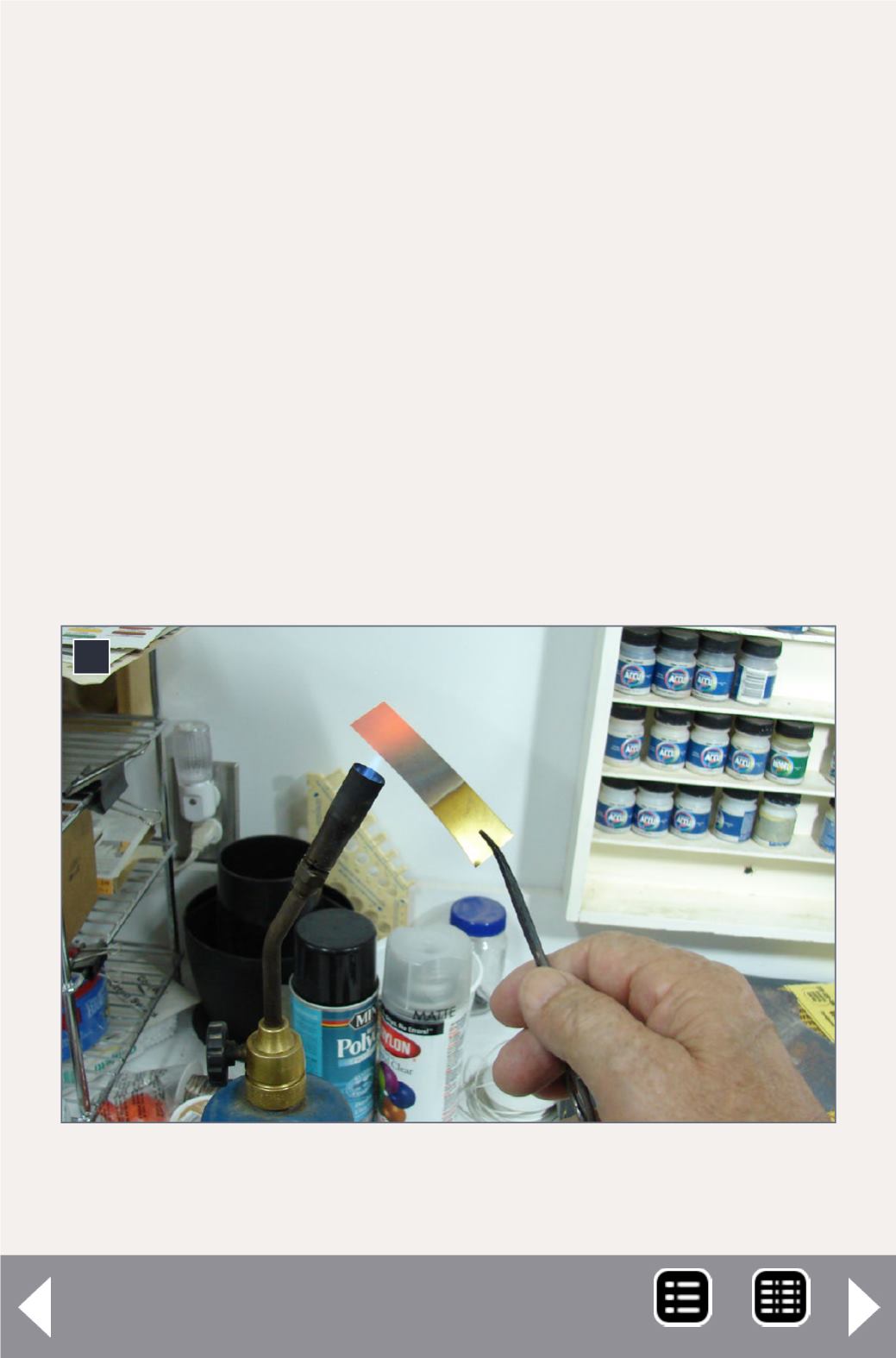

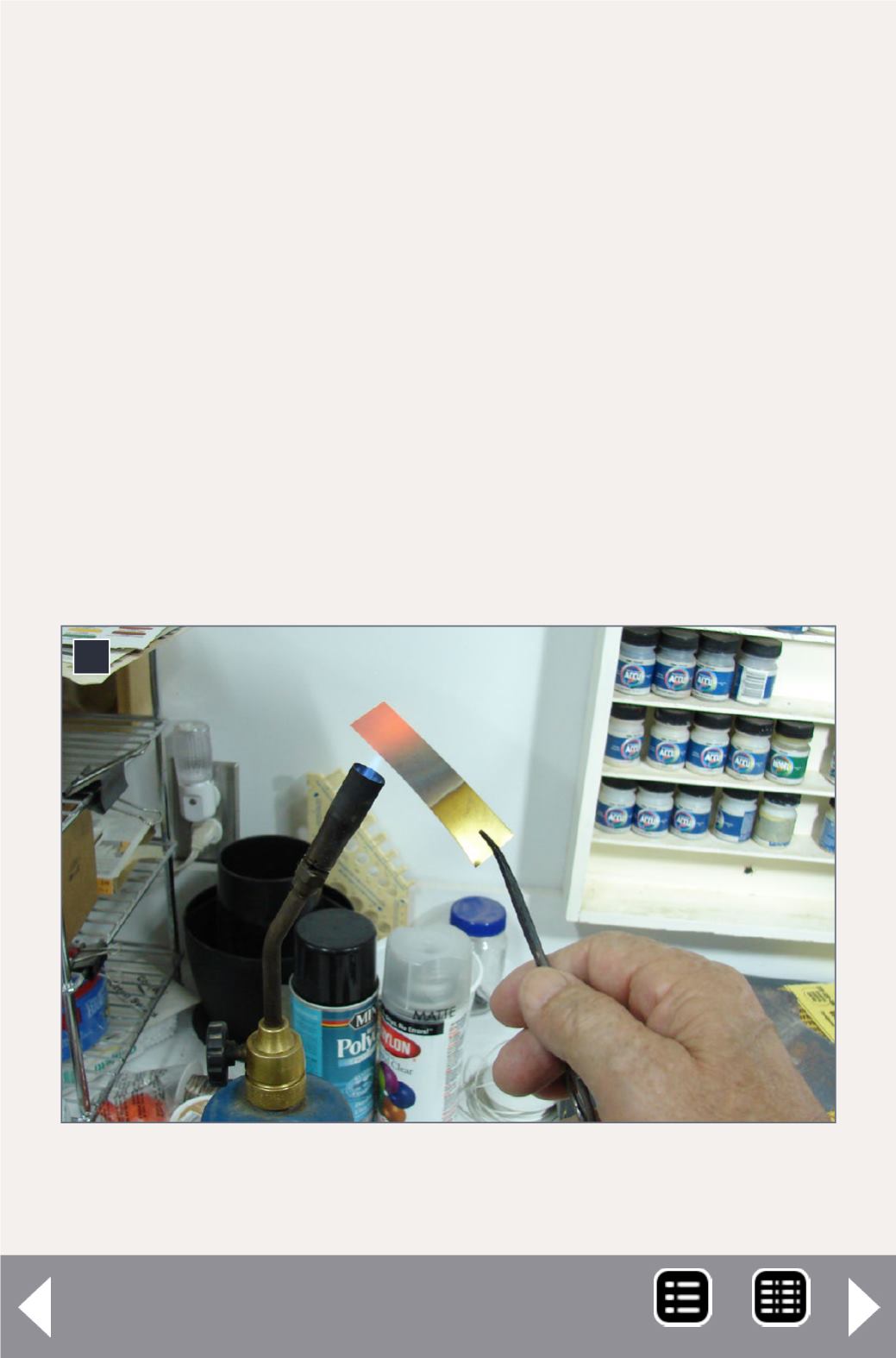

I startedwith some .010” thickbrass sheet stock, andafter

trying several different approaches, I settledonusingheat to

anneal (soften) thebrass, turninga3/8”diameterwooddowel

in thedrill press for thepunchor forming tool, andmillinga

concavearea intoawoodblock for thedie. Heating thebrass

toa cherry red color and thenquenching it softened it suffi-

ciently toallow thebrass to form the reflector in thedie (2).

Once thebrasswas annealed toa softmaterial, I began the

processofmaking the reflector by chuckinga3/8”dowel ina

drill press andbringing the turningdowel down to thebrass

plate, to force it into thedie in thewoodblock (3).

2

2. The brass is heatedwith a plumber’s torch, near a

bowl of water toquench the brass, tomake it very soft.