Some clamps work fine and others don’t. Generally, once I

realize a clamp isn’t working out, I regulate it to a secondary

status. The box in my tool drawer for my clamps can actually

hold a lot more than I have, so there is no incentive to toss

out those clamps that don’t work. As long as I can quickly

find the clamp I want, the secondary ones get to stay for a

while longer.

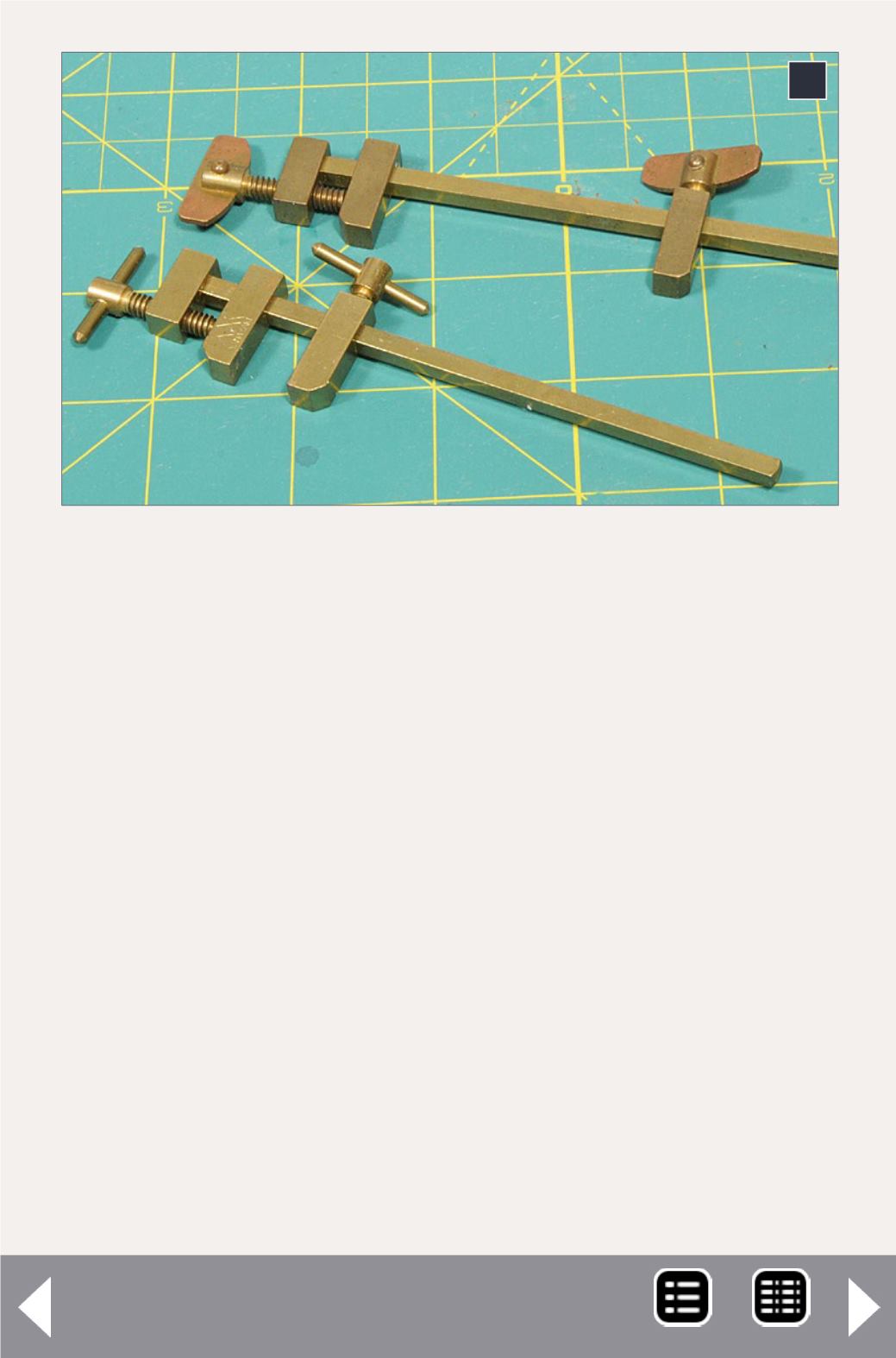

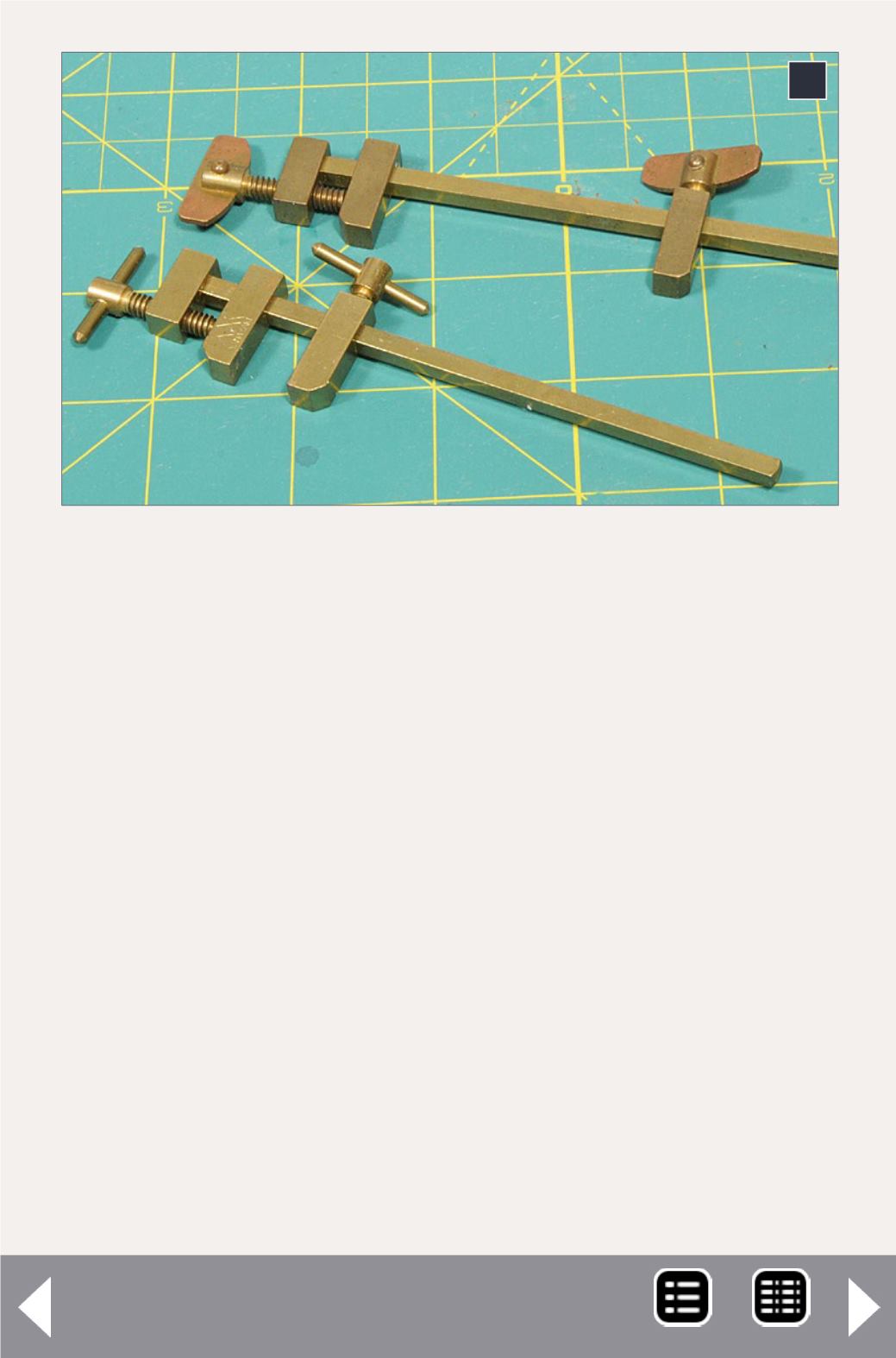

The brass bar clamps, as sold by Micro-Mark and shown in

(7), work as intended. These clamps might work well if you

build laser-cut wood structures and need to hold side/end

assemblies in place while the wood glue dries. To use one of

these clamps, you need to set the sliding jaw slightly wider

than the object being clamped before gluing the joints

together, but with the sliding jaw unlocked. Once the parts

are assembled, you can hold the assembly with one hand

7: Here are 3½" and 6" brass bar clamps. The wing head

thumb screw on top of the sliding jaw allows the jaw to be

locked in place, with final clamping provided by tightening the

end wing-head thumb screw.

7