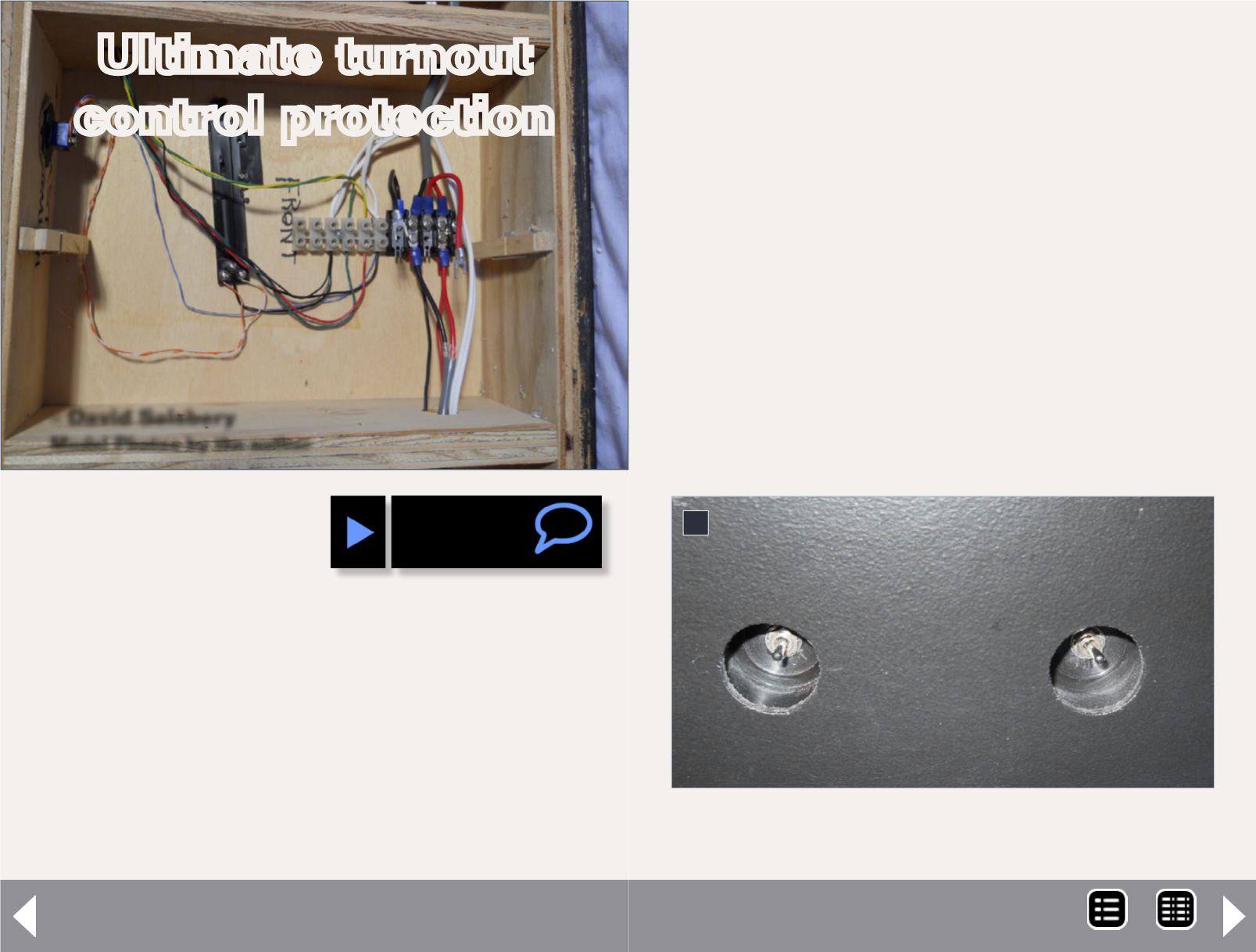

Ultimate turnout control protection - 1

I

started building modules, I knew that I wanted remote turn-

out control. This is the method I use to keep my control

switches from getting damaged. The modules get moved

around a lot and this has worked awesome for years now.

The turnout controls are flush-mounted in the operator side fas-

cia, and control the turnout motors mounted under the table.

My controls are mini momentary center-off toggle switches,

mounted to 1 ¼” “tips” from Ace Hardware. Spring-loaded

momentary switches are needed for twin-coil snap-action

Protect your turnout

controls from getting

hit accidentally ...

Ultimate turnout

control protection

– David Salsbery

Model Photos by the author

machines like Atlas and Peco. For stall motors like a Tortoise,

use a standard toggle switch. The toggles are mounted into a

¼” hole drilled into the frame. A 1” hole in the fascia material

gives access to the control (1).

Ultimate protection for traveling

This same method could be used for larger toggles but you

will need to use a larger cup or tip, like a cap for PVC plumb-

ing material, and larger holes. The mini toggle switches and

the tips are nice for modules as they are low profile, which

helps protect them from damage underneath as well as from

the outside.

The modules have a mix of Atlas and Peco turnouts and switch

machines. They all work great, but I like the Atlas products a

little better because of the lower profile of the switch machines

and their quiet operation.

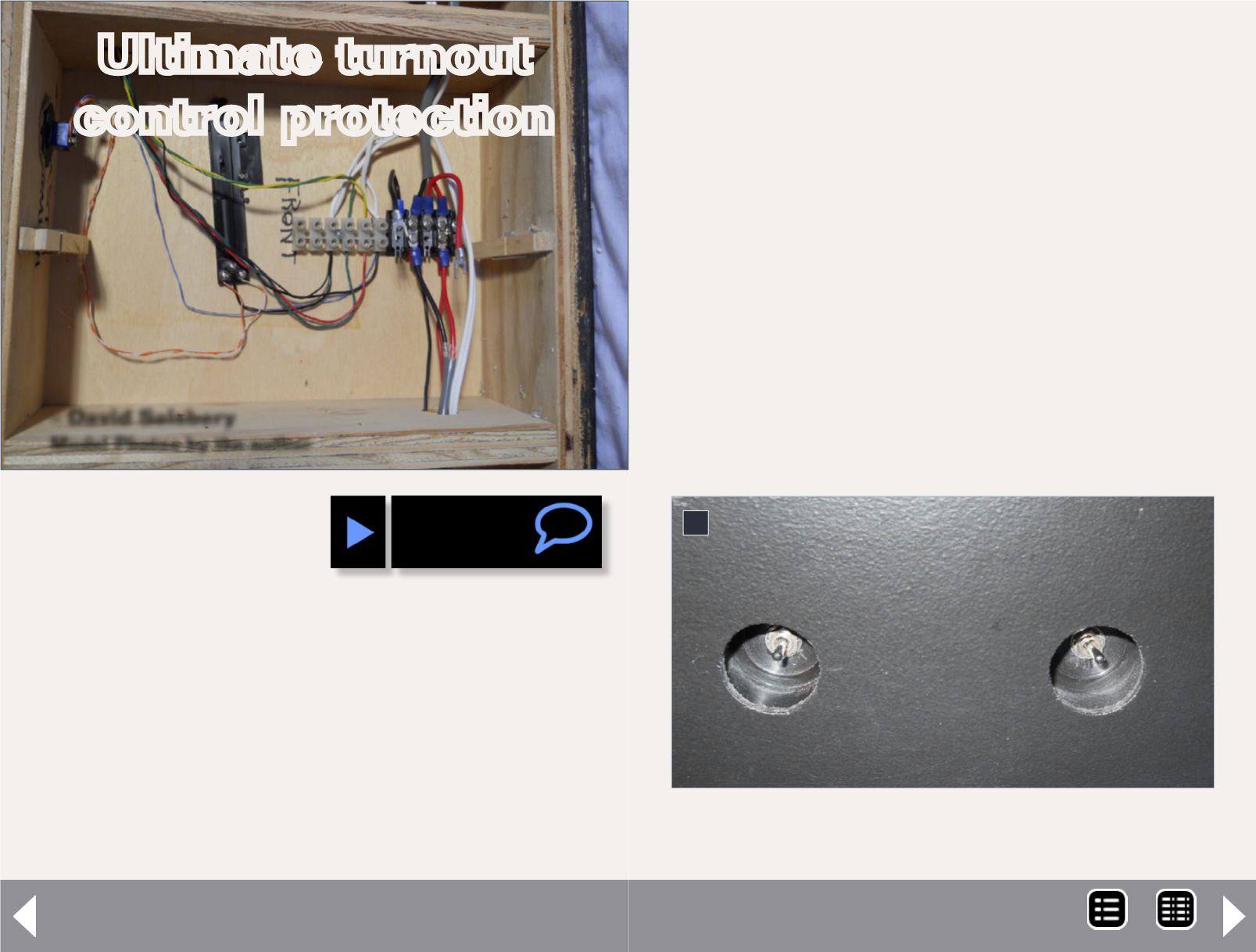

1

1: Recessed toggle switches are protected from

damage and accidental use.

MRH-Feb 2014