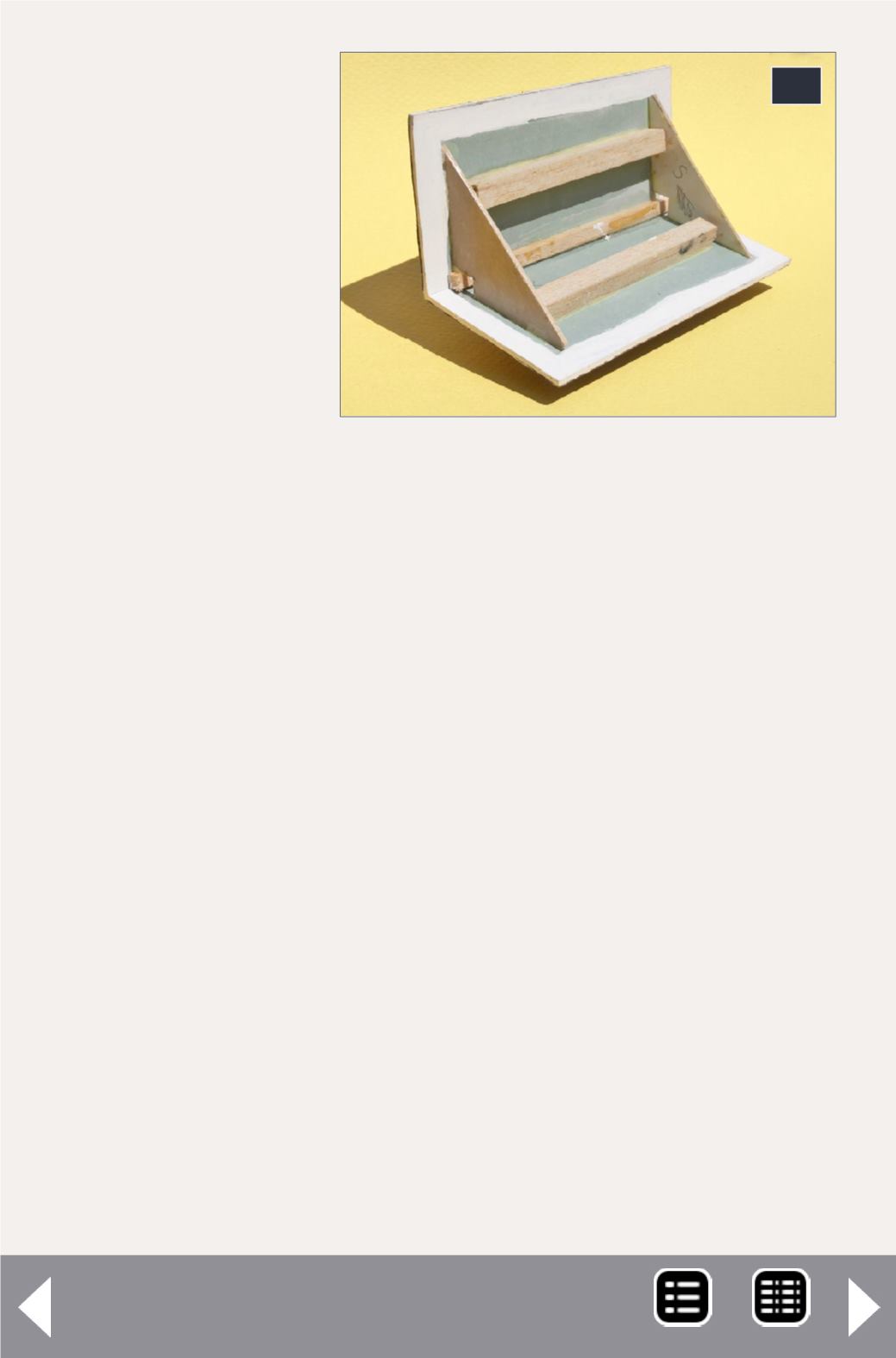

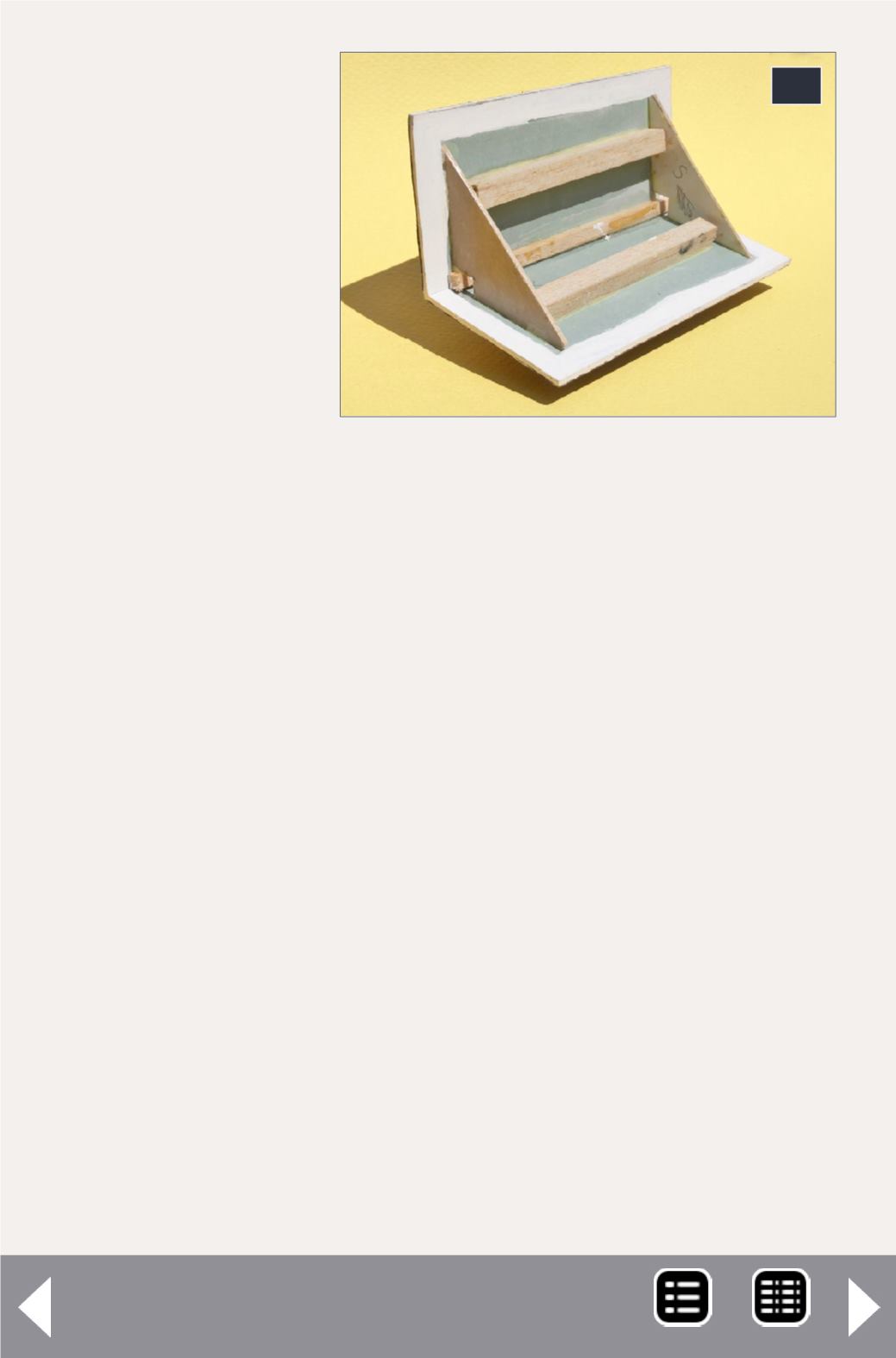

the inside of the

completed structure

(32) – very simple

styrene modeling.

Almost all my struc-

tures have remov-

able roofs, for future

access to replace

window glazing, add

lighting if desired,

and so on. You can

see the roof con-

struction for this

structure (33), which

is heavy cardstock

amply reinforced. I

modeled the sides of

the clerestory atop

the roof with styrene

clapboard, to sug-

gest louvers in the clerestory.

An end view of the ice house (34) shows where drive-up cus-

tomers would purchase ice. A small-town ice facility like this

would likely manufacture small amounts of clear ice for con-

sumer sale, but would have limited ability to produce ice in

the quantities needed for icing refrigerator cars around peak

harvest season.

I present an overview of the ice house and deck here (35). The

deck is entirely of stripwood, pre-stained and built board-by-

board, and supported on bents hat were constructed using a sim-

ple fixture to ensure that they would be identical.

33: The ice house roof is made

from heavy cardstock, thoroughly

reinforced inside with quarter-inch

square balsa and with cardstock

roof formers to ensure matching

roof pitch with the building ends.

The outside of the roof has mask-

ing tape cut into strips to simu-

late rolled roofing, and painted

medium gray.

33