Questions, Answers & Tips - 2

After gluing, I set the coupler aside for several hours to dry.

Usually I assemble 50 or so at a time, so I just line them up on a

desk to dry.

The next day, I either start using the couplers or put them away.

Before installation, I coat both sides of the knuckle with graph-

ite, as well as the pushing surface of the coupler. I do this for a

pair, usually to go on one car, and then I couple the couplers, and

slide them up and down while stretched and bunched, several

times in each state. Finally, with them bunched, I turn them over

and let the balls get out of the way. Then I pull them apart and

push them together in such a way that it forces both knuckles to

open fully and close fully. I do this several times, until I am satis-

fied that both couplers are opening and closing smoothly. If any

fail to open or fail to lock, they go in a separate pile for me to fix

or toss, depending on the cause.

2

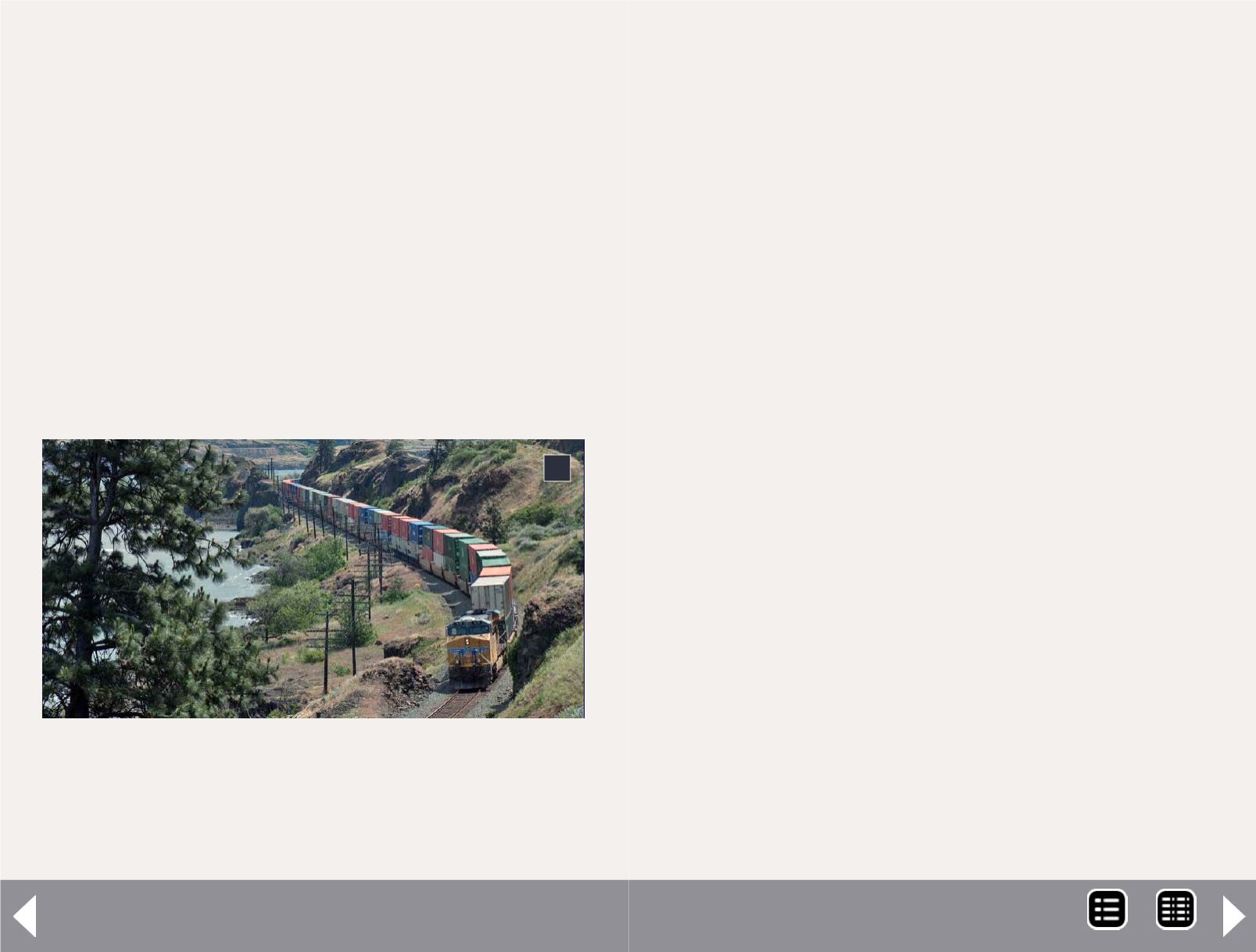

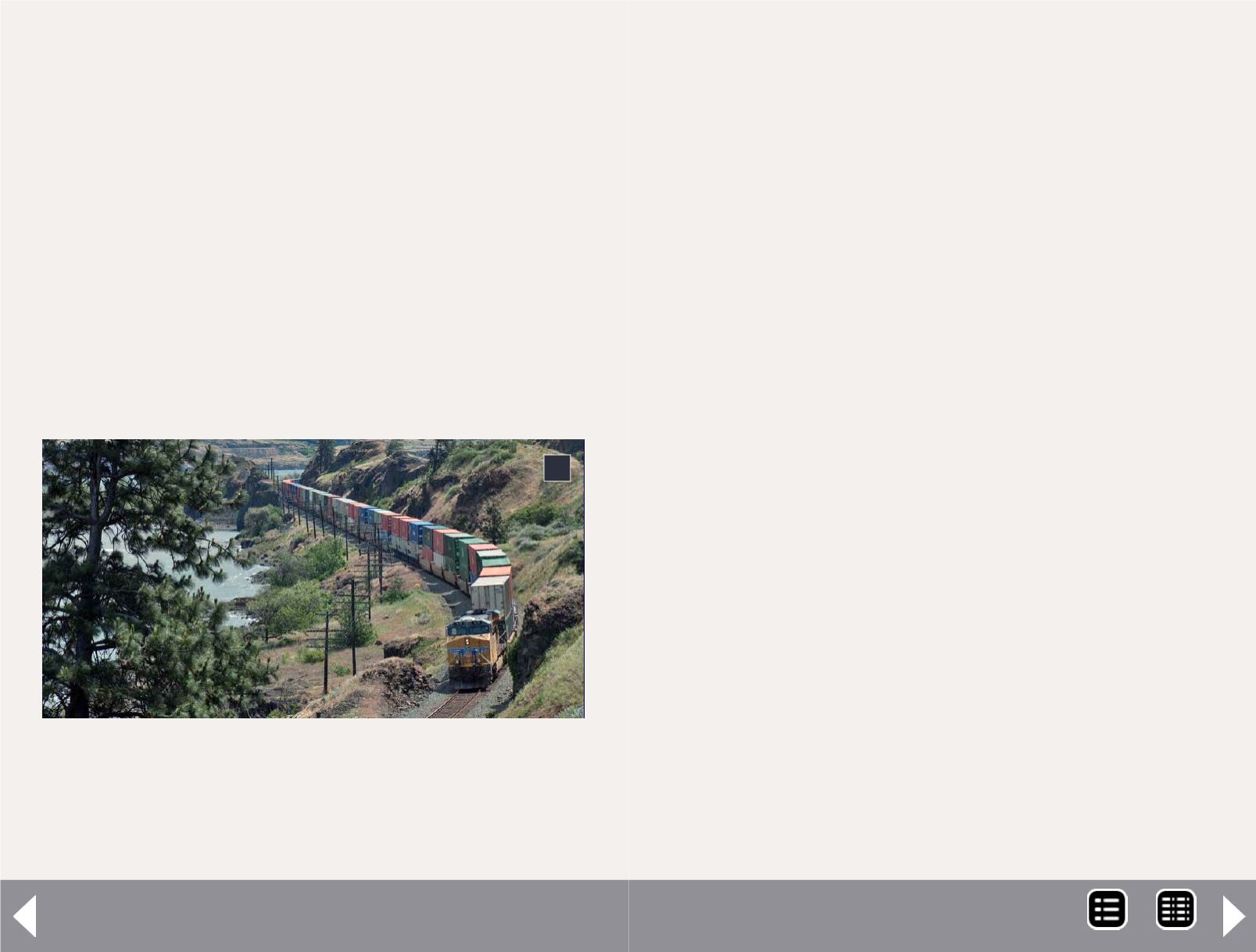

2: This Union Pacific diesel unit, eastbound at Rowena,

OR, is a distributed power unit (DPU), not a helper.

DPUs on level track can be represented by careful

speed-matching with the head-end locomotives, or else

by adding a dummy engine.

Some of the coupler styles only come assembled and are not

available as kits. For those, I graphite both sides of the knuckle,

the pushing face, and apply as much as possible in the slot on

the back of the pushing surface, so that some graphite gets into

the ball and knuckle tongue area. Before installing them, I go

through the same break-in procedure as the kit couplers. The

factory couplers can be disassembled if they have problems, but

that must be done with some care. I have rebuilt a few particu-

larly uncooperative ones, and they operate just fine now.

– James Ogden

The only thing out of your recommendations that I did not do

previously was to apply graphite to all the internal parts. All the

couplers passed the upside-down working test before installa-

tion, and all of the working surfaces of the knuckle were pol-

ished with a graphite pencil in the same manner that James

suggested.

As an experiment, I went back and looked at some of the cou-

plers I've been having problems with and applied some graph-

ite inside. I took a tube of graphite, made a small pile of it, then

took a fine brush and picked up some of it, carefully placing it

inside the assembled couplers both upside-down and right-side-

up. I then used the magnet wand to cycle the locking ball several

times to be sure that all sides were coated. I'm happy to report

significant improvement.

When I assembled all these, I was not a stickler for flash. I looked

at only the two spots recommended on the instructions. Now I

know a few other places to check.

– Kevin

Taming helpers

Q.

We are trying to run helpers on my layout, which includes

several 2% grades and 30" radius curves. So far we have shoved

MRH-Sep 2013