Comme-N-tary Column - 5

6

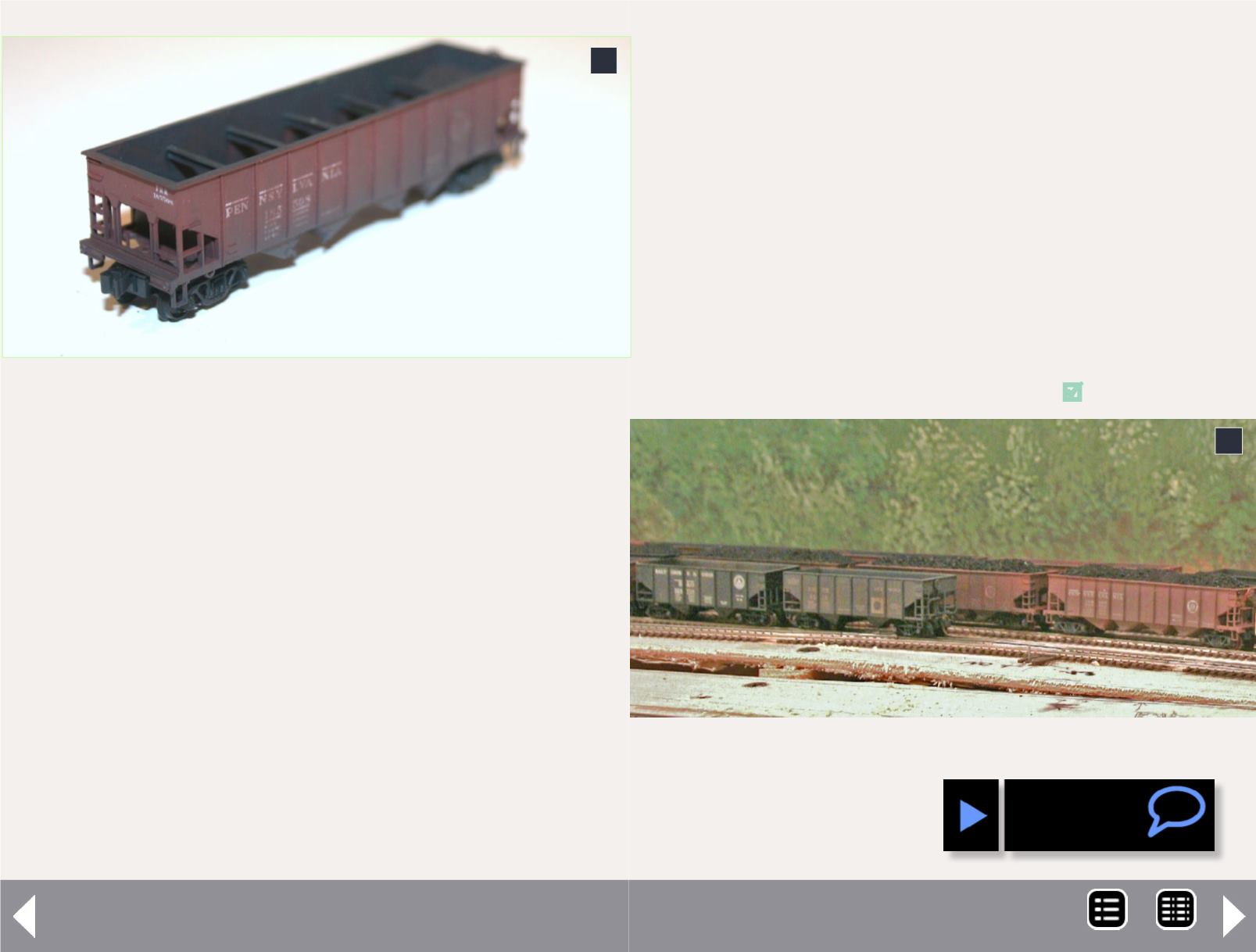

6: Internal bracing is applied to a PRR four-bay hopper

using plastic I-beam shapes.

top chord reinforcing angle between the bolsters. An Evergreen

.060" angle represents this perfectly. These modifications can

be painted to match the factory paint jobs; PollyScale Boxcar

Red is a pretty good match.

Weathering

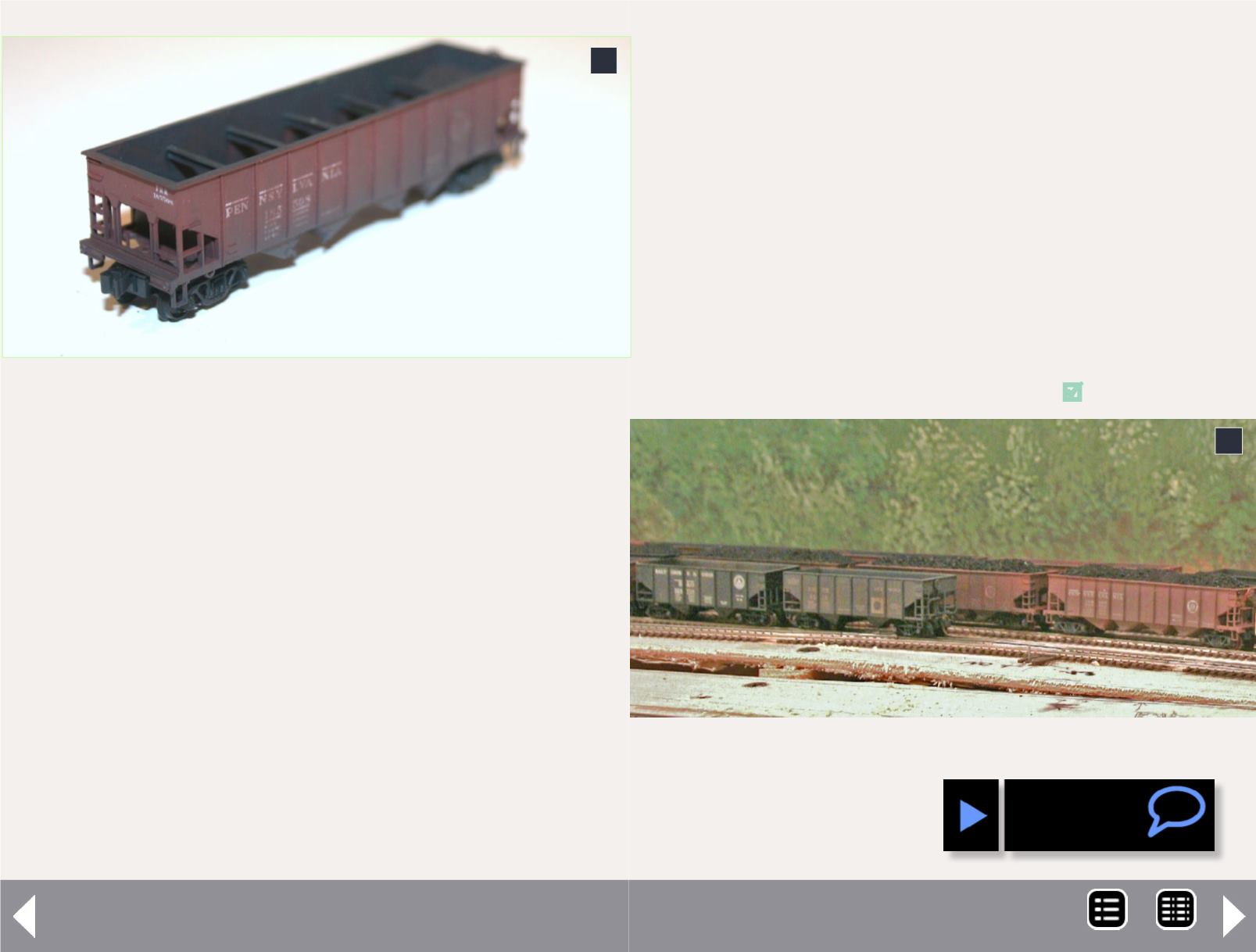

Hopper cars take a beating. They are showered with coal dust and

suffer from the harsh minerals in the coal dust soup that rains on

the cars in bad weather. And there are a lot of cars to do.

Fortunately, an airbrush does a great job of representing coal

dust and can ‘ruin’ a bunch of cars in a hurry. I try to work on a

dozen cars at once. Before airbrushing on the coal dust, I add

a few dark rust splotches irregularly on the sides of the cars.

Some of the lettering can be faded using a rubber eraser.

PollyScale Grimy Black is a great color to use for coal dust. I

airbrush it on greatly thinned to add just a little color at a time,

using vertical streaks. Repeated passes gradually build up a

heavier coat of coal dust. Leave some of the cars with a lighter

dusting to create a nice variety in the fleet.

Summary

These upgrades produce a great-looking fleet of hoppers.

Weights and weathering are added to all the cars in the fleet.

Add internal bracing only to the cars that will run empty. The

more ‘cosmetic’ weights also go to the empties.

Fully automatic magnetic couplers are included on the cars that

will be switched on local freights; non-operating body mounts

are installed on cars that will be backed in cuts; and non-oper-

ating truck mounts on mainline consists that won’t be switched

at all. A little prior planning can save time and money by apply-

ing only needed upgrades to each set of cars.

7: A set of empty and loaded hoppers weathered with

paint and an airbrush.

7

MRH-Jun 2013