DCC Impulses Column - 8

They are much less expensive than buying ready-made connec-

tors. The big trick is insulating them and marking them.

Here’s how I insulate

them. I use 3/64" shrink

tubing

If I have a lot of pins, the

shrink gets too tight. Then

I put the shrink on EVERY-

OTHER pin. Then I put a

larger shrink tubing over

the entire connector. That

way all pins are insulated

from each other and the

total package is insulated

from shorts to the frame,

and other conductive parts.

Finding space

The best way, in my opin-

ion, to find whether your

installation will work before

you buy the decoders and

speakers, is to try it.

I use the data from manu-

facturers' web sites to make wood mockups of the decoders and

trial fit them before hand. I make the mock-ups a bit oversized to

allow for shrink tubing hang-over and clearance for wires.

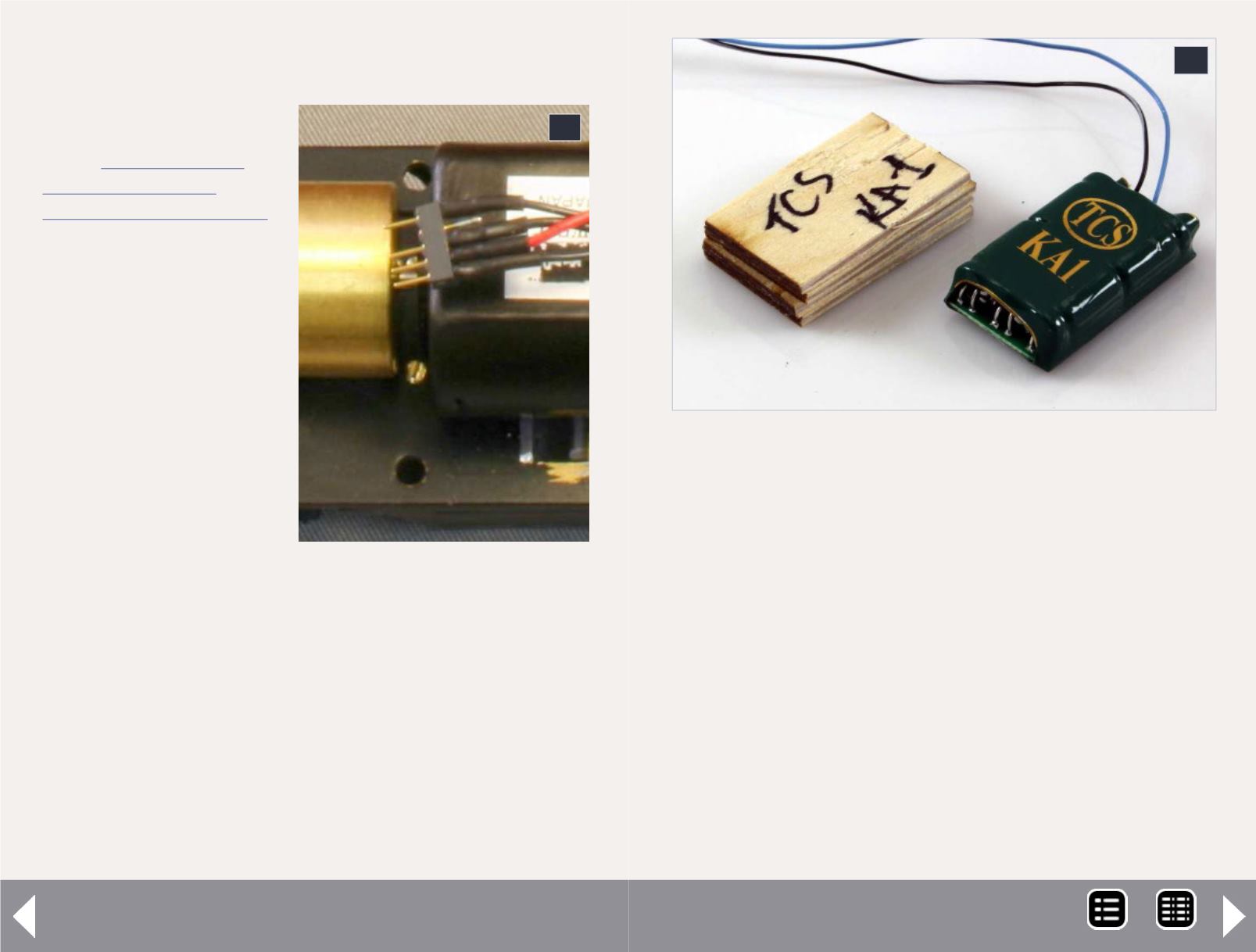

14: This photo shows a connec-

tor with 3/64"shrink tubing on

the connections, ready for an

overall sleeve to insulate and

stabilize the entire connector.

14

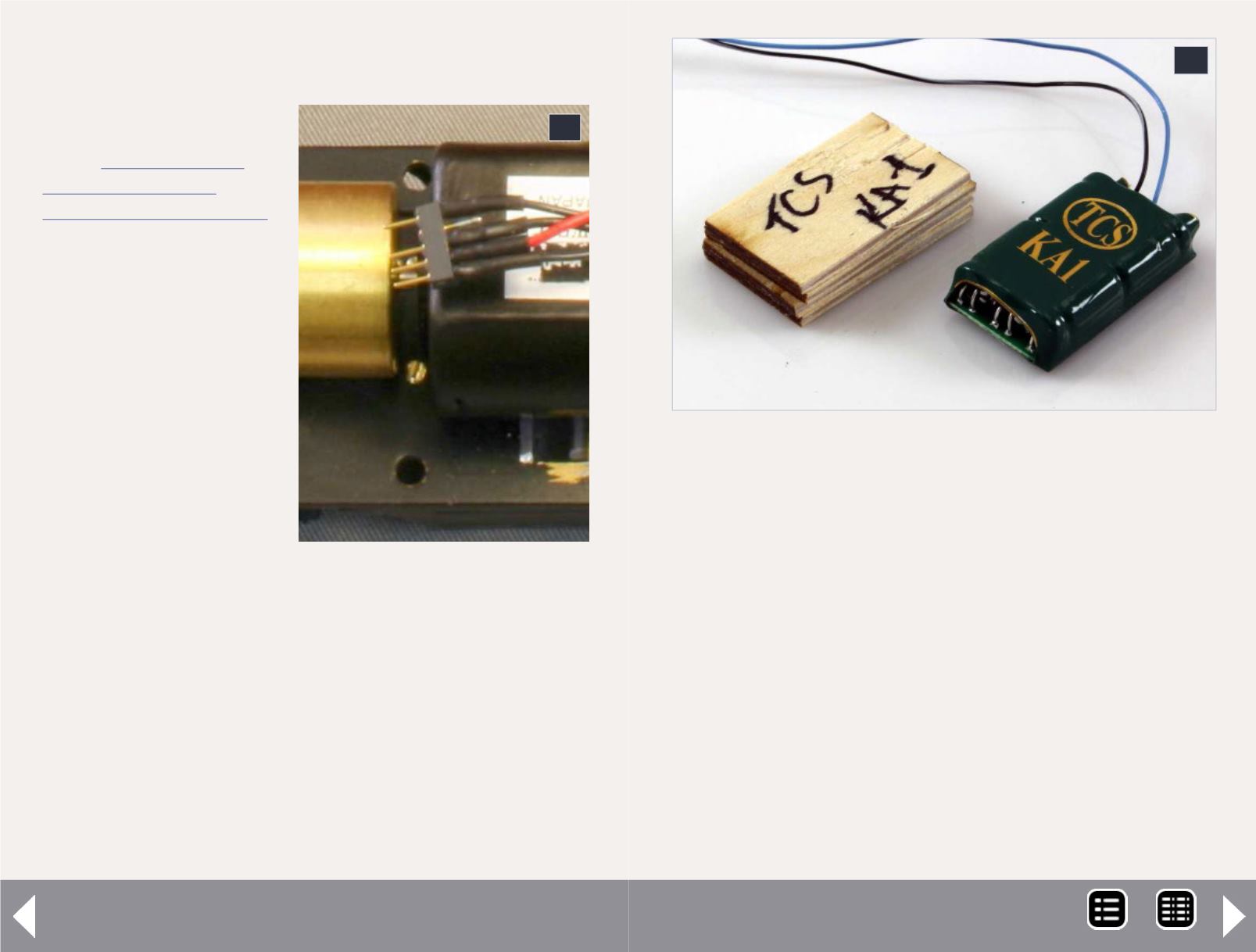

15: This photo shows the mock-up I made for a TCS KA-1 and

the actual part after I got it. I was able to verify that the KA1

would fit before I bought it with this mock-up.

15

Glue it fast

The wood mock-up discussed in “Finding space” was built from

bits of wood from a Fast-Tracks project, assembled with Pacer

Formula 560 Canopy Glue.

I don’t like this glue, I LOVE it.

It glues almost everything. It dries clear, so you can even use

it to make windows. It is fantastic for installing glazing. It even

works as an incredibly fast drying wood glue. I’ve built entire

loading docks in a very few minutes, assembling the parts on

waxed paper! Even though it will glue almost anything, it works

best on the more porous surfaces, like wood and plastic.

MRH-Jun 2013