is extended as needed to put the blade in tension and the frame

locked into place. If the saw frame flexes or the blade flexes too

much, the blade can easily break. It is exasperating to put a new

blade in place, tension it as much as possible, and then have the

blade break part way into the project due to flex. Other times,

the blade would pop out of the clamps as I tried to tension the

saw frame, another aggravation.

The shortcomings of my inexpensive jeweler’s saw could prob-

ably be overcome by taking more time to carefully position the

blade in the clamps and tension the saw frame as much as pos-

sible. But I don’t have much patience, especially when it comes

to the tools that I use. Instead, I prefer to replace the tools that

don’t meet my expectations. After all, this is a hobby and I don’t

like to use tools that cause me frustration.

I found a replacement jeweler’s saw at Otto Frei, a jeweler’s sup-

ply company in Oakland, CA. It is a saw frame made by Knew

Concepts of Santa Cruz, California. Here is a link to the saw

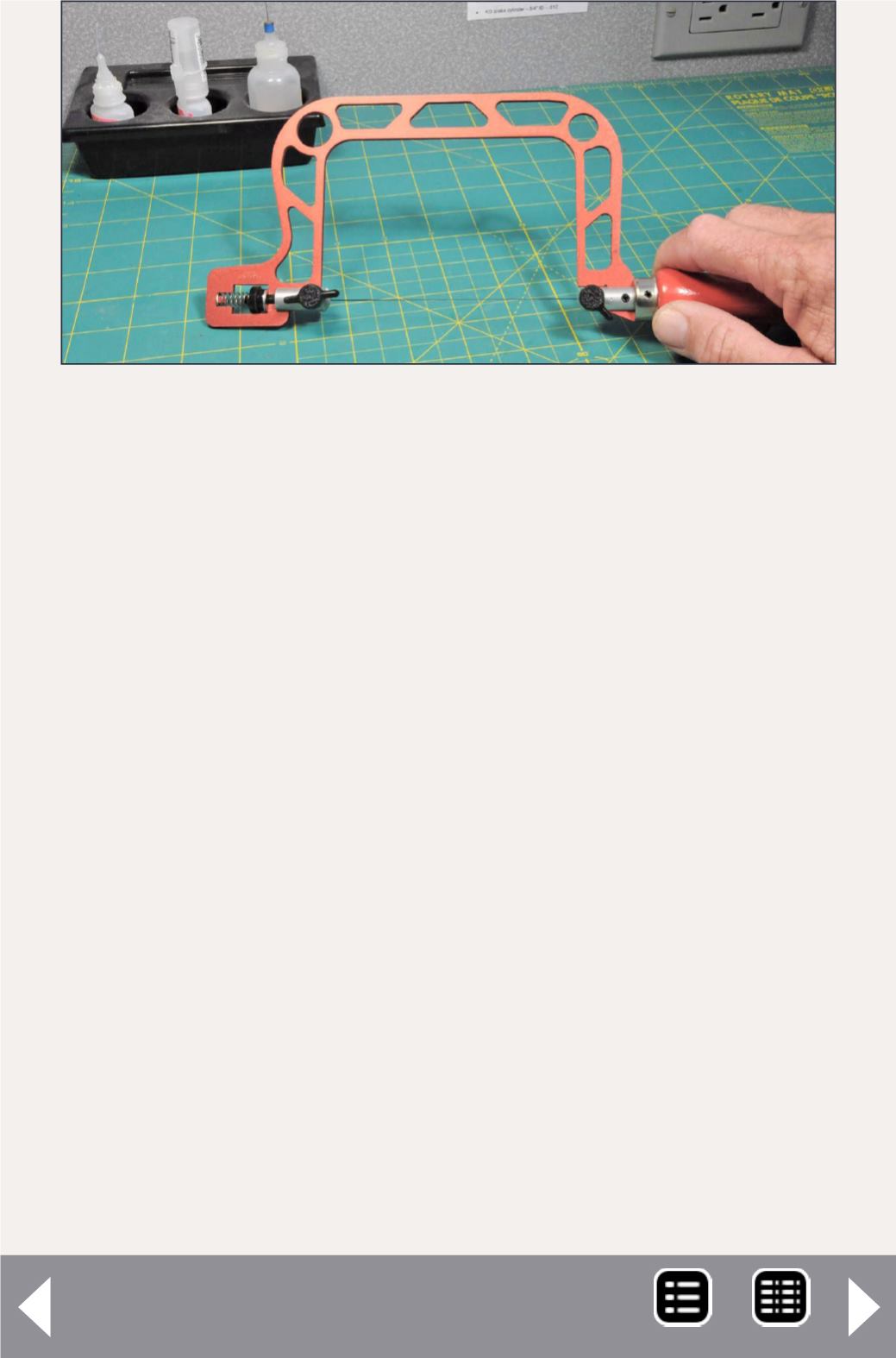

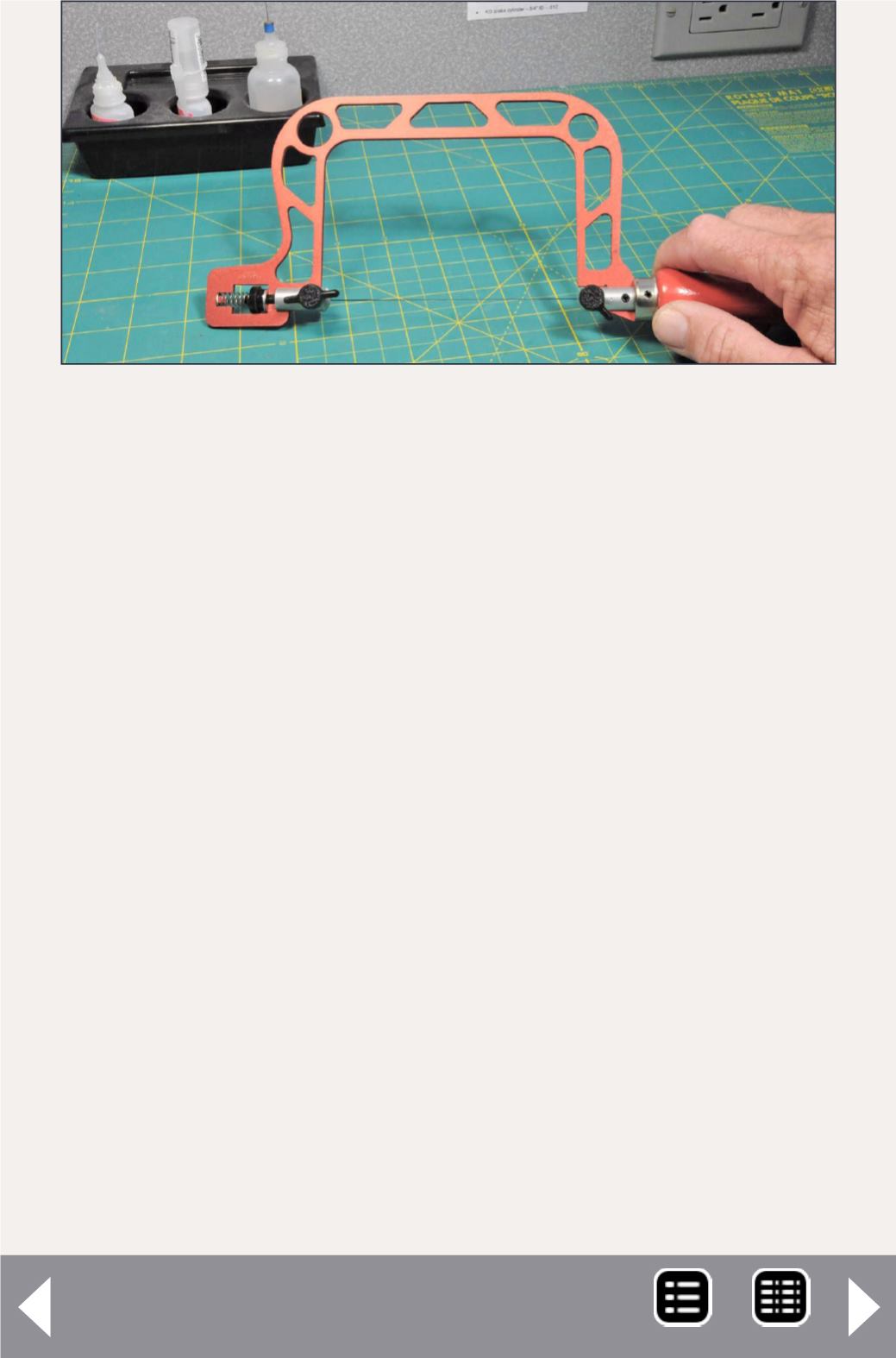

1: This is the Knew Concepts jeweler’s saw. The frame is laser-

cut from aluminum. According to the manufacturer, “…red col-

ored handles are used because clinical trials have shown that

the color red promotes accuracy.”