2

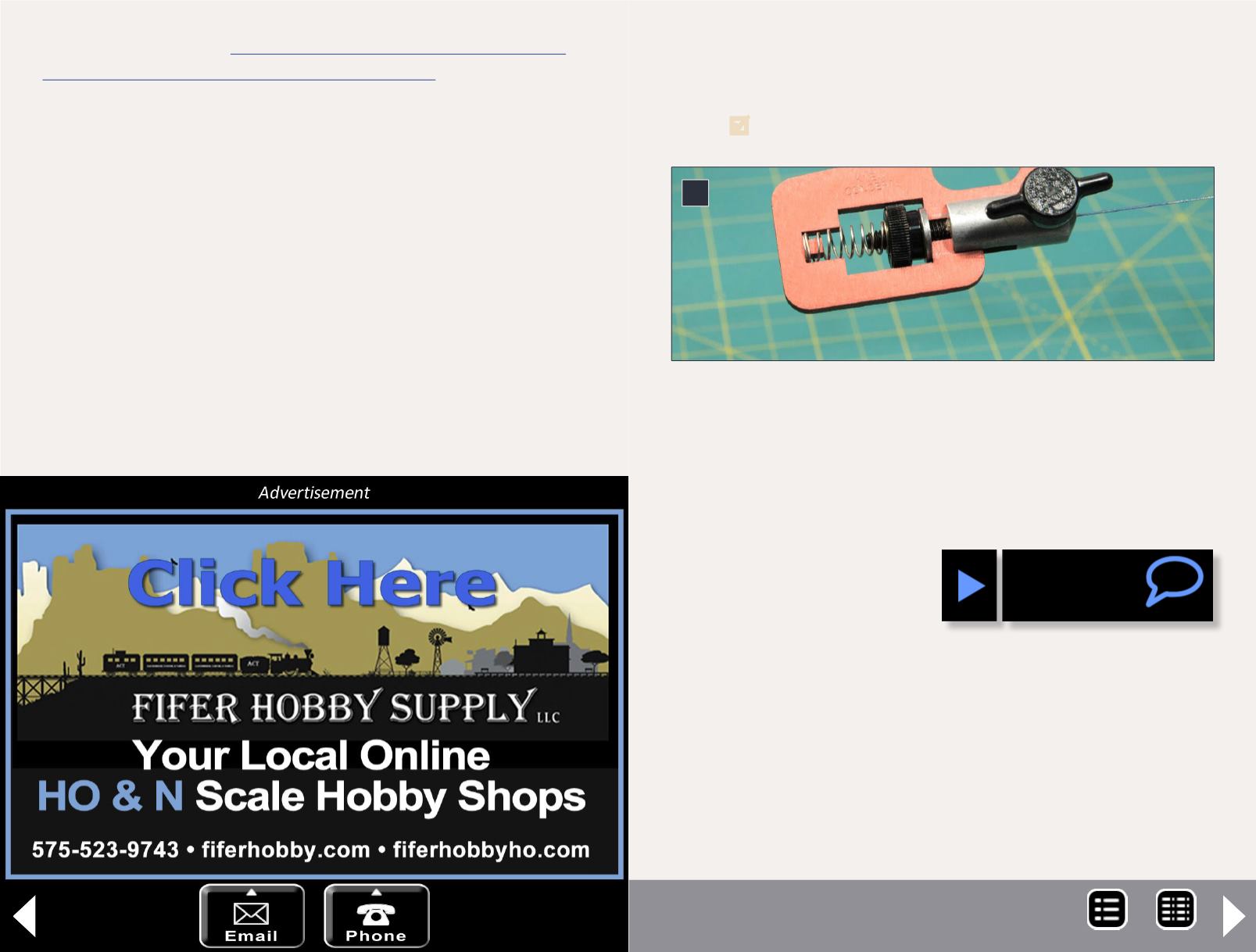

2: A close-up of the blade holder and tension adjustment. The

blade is inserted into a small hole in the grey-colored collet and

locked in place with the black clamp screw. Blade tension is

then adjusted with the spring-loaded adjusting knob. The blade

should be adjusted until you are satisfied with the “ping” when

the blade is flicked with your finger.

ence in cost between a quality tool and the less expensive tool

is appreciated every time you use the tool.

Disclaimer - I love good tools and don’t hesitate to invest in

them.

frame (item 149.653):

The design of this saw frame is absolutely rigid, minimizing saw

blade breakage. Blade placement is simplified by a design in which

the ends of the blade are inserted into small holes and clamped

into place. This eliminates the problems associated with the blade

not being parallel with the frame. Once the blade is clamped into

place, it is tensioned by a spring-loaded knob on one end of the

frame. Much simpler! These saws are made in the USA using only

USA-made parts including the screws. The saws use the same

small blades as the hobby-quality jeweler’s saws.

These saw frames cost $47 each compared to about $15 for

the standard hobby-quality saw frame. I think that the differ-